Engine: 289 Windsor

Trans: C4 Auto

Diff: 8 3/4" Sprint

In the meantime, Troy had changed his mind and decided he wanted a V8 powered XPso, after considering all their options, the decision was made to sell the white Fairmont and carry out a full rebuild on the $600 'parts car'. After stripping it down, it was discovered much more work would be required than first thought. All four floor wells were rusted but fortunately the sills and pillars remained quite solid. John formed some replacement floor pans and welded them into place. Both front door were replaced with N.O.S whole doors while the original rear door frames were fitted with N.O.S outer skins.

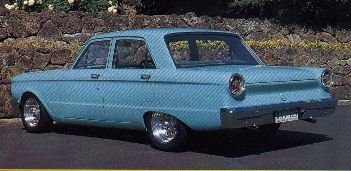

Similar hand made panels were made to enhance the underside of the floorpan. They are held in place by button head stainless steel fasteners. With all the body repairs and improvements completed the whole car was painted in approximately 12 coats of Spartan Pastel Green acrylic. Everything that could be painted was painted the same as the body colour and all the original brightware was either rechromed or polished for a totally rejuvinated look.

Transmission in the Falcon is a C4 auto which has been fitted with a shift kit and has a borg-warner trans oil cooler mounted on the front of the radiator core. The diff is an 8 3/4" American Falcon Sprint and a stock XT Falcon tailshaft bolted straight in without shortening and uses the same size universals. Rear springs have been reset three inches lower than standard and had two extra leaves added. The front suspension was lowered by using a pair of two inch lowered spindles and a pair of 1 1/2 inch lowered springs. Pedders gas filled shock absorbers are used front and rear. Front brakes are ventilated HQ Holden discs which have been redrilled to Ford bolt pattern. The XP rides on a set od Cragar wheels, 15x6 and 15x7 fitted with Yokohama 205/60 and 215/60 series A509 radial tyres.

Absolutely every aspect of the car is either new or thoroughly reconditioned. The pastel green theme continues into the interior with the dash, instrument cluster, steering column and seat bases all colour matched to the body. The grey velour upholstery material is used extensively but it is highlighted with green piping. Front seats are Sigma buckets and the rear bench is a stock XP seat. The standard instrument cluster is complimented by water temperature and oil pressure gauges mounted in the console for the B&M Megashifter. A SAAS Twirler steering wheel is fitted to the stock XP steering column and the original heater/demister unit has been retained. Inertia reel seat belts have been fitted for all occupants.

Troy and John spent two years working together on the Falcon. One week before last years Muscle Car & Mega Bike Show in Melbourne, the car was being detailed to appear in the show when it slipped off the jack which had been placed on the diff before smashing into the fuel talk and carrying on its destructive path up into the floor of the boot which then looked like it had a hill in it. Put yourself in this position andit would be very hard to describe your feelings, but the show had to go on and after burning much midnight oil repairing, repainting and reassembling the car, the XP made it to the show on time.

At the end of the weekend all the extra hard work was rewarded with the car winning 'Top Engine Bay' and '2nd Street Machine' in a field of high dollar pro-built cars. All aspects of the XP's rebuild including all the painting were carried out in the Thornbury's backyard workshop. Others who assisted in the end result were Don Burton at Don's Motors - mechanical; Mark Craig at Milner's Upholstery - interior trim and Dave Inge at Inge Bros - auto electrical work. The car is fully engineer approved and street legal.