Working With Unusual Materials

Since I have been making klingon costume, due to the weight of

the materials, I find it necessary to use under support for

certain areas. I like to work with metal mesh. They can be

found at the hardware store in various weights and sizes. The

weight of weighted metal wire use to create the mesh. The

size refers to the size of the cubes in the mesh. The mesh

may be very lightweight using a nylon strand to create find

metal mesh tiny cubes. This is usually used for screens.

The larger mesh requires metal cutters to cut the mesh.

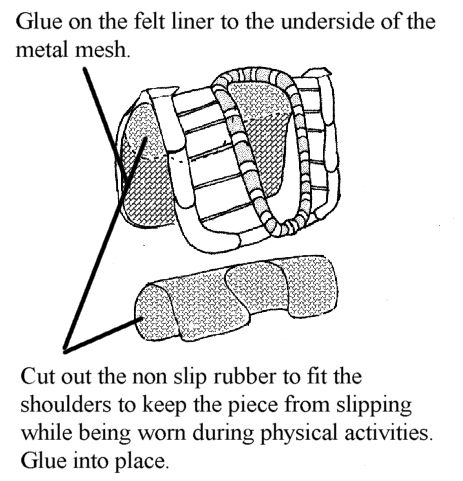

It is intended for creating farm cages and fencing.

When working with the meshes I have found that they can all be sewn with the sewing machine. I usually start with the top material. I candidate to shape and assemble as required. If the material is thin or will show the mesh through it, I sew a layer of interfacing underneath. I then sew them to the metal mesh. I always cover the bottom of the metal mesh with inappropriately colored felt. The felt can be sewn on or glued with Sobo glue. When cutting out the mesh I trim off all the little pieces that stick out. If I am working with a heavy gauge mesh, I bend over all the end pieces and wrap the edge with felt. This is particularly important when it will be to the skin.

Style 1

Style 2

When traveling with metal mesh it may get squashed in luggage. Just reshape and there should be no problems.

Style 2

Style 1

When cutting aluminum I usually use a grease pencil to market the pattern on the surface. I use a jigsaw to cut out the general shape. I use a grinding wheel and buffing wheel to clean up the design. I have found that a dremel can work in small corners better than the larger wheel.

Style 2

Style 1

If the aluminum is thin, I may sandwich it in between wood. If it is very thin, I use metal snips to cut out the design. When using this snips, you have to be careful to cut in a long smooth motion. Sand the edges and remove any burs. I either rivet the metal in place, or I drill it and sew it on with Kevlar thread. If the metal has to be attached to other metal or wood I use Velcro adhesive.

When working with brass there are some extra steps you must take. First of all, I only work with thin sheets of brass. I use metal snips to cut out my design. I pre-drill any rivets I might use. I then sand the edges and buff and polish the brass. I then gave it a coat or two of sealer. If you don't you will have every fingerprint showing each time you touch it, and the brass will tarnish between wearings. Once the brass is completely dry, I then applying it to the project. You may have to periodically re-touch pieces that get scratched or get a lot of wear.

Style 1 printable pattern

Style 2 printable pattern

Creating the doral tail.