Taig lathe mounted on blocks to suit my preferred

working height, swarf pan added and various other modifications

4-step sheave adapted to Taig to suit

'universal' drive motor mounted inside work bench.

Tailstock lever extension made from old nut driver

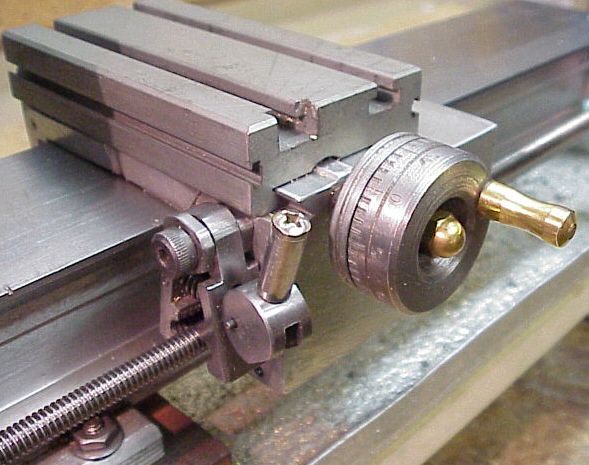

Lead screw (1/4-20 UNC), engaged split nut and

locking lever. Face of carriage milled flat and square

Split nut disengaged.

Link and compression spring barely visible

Shop made steel knobs on tailstock. Leadscrew bearing assembly mounted under lathe bed

Aluminum leadscrew knob and steel index bracket. 1 revolution = 0.050" travel

Steel carriage locking knob. Small diameter to allow cross slide travel. Note depth stop moved to rear of headstock

Index plate made with Dividing Head; 'barrel bolt' style locking pin mounted on headstock

15:1 speed reducer to get reasonable sfpm on larger diameters of stock

Note turnbuckle tensioner.

Motor under bench has pivot mount so tension is supplied by it's own weight

Another view showing a work-piece in the 4-jaw chuck