|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Standard Slag Company

1962 - 1989 |

|

|

|

Back to Directory |

|

|

|

|

|

|

|

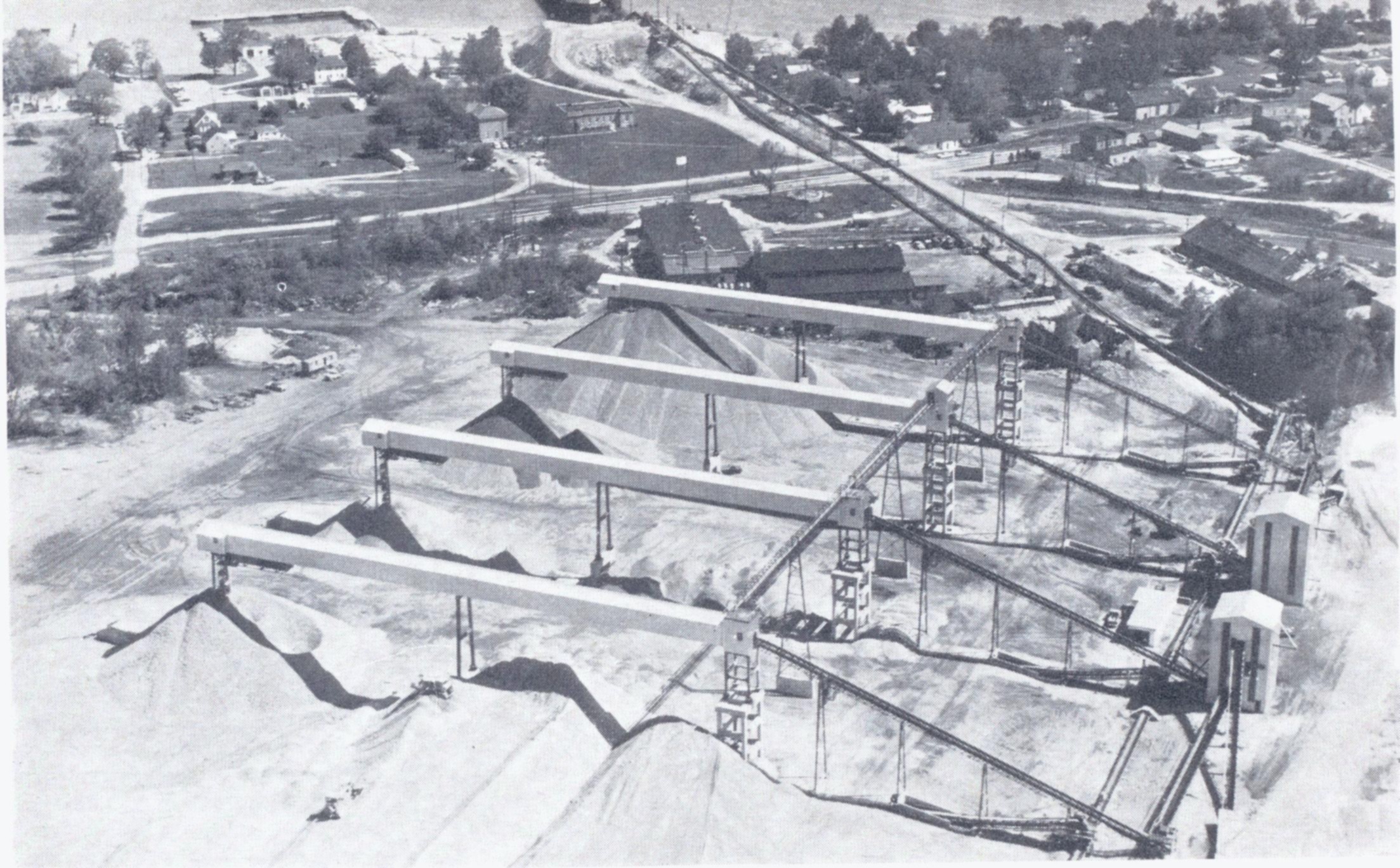

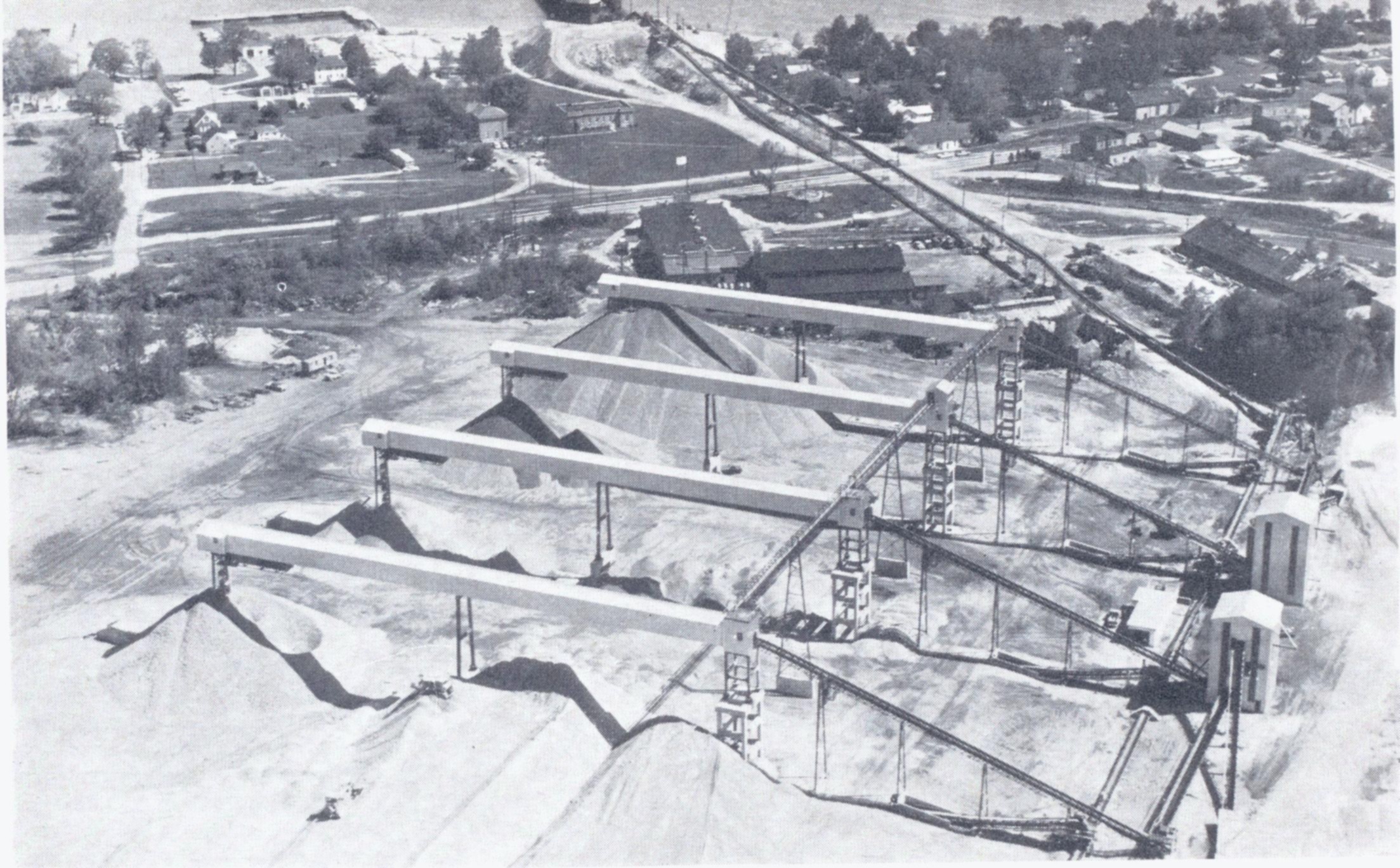

Standard Slags new plant in phase one of a two phase project. The plant was state of the art at the time of completion in 1964 |

|

|

|

|

|

In December 1962, The Standard Slag Company based in Youngstown, Ohio took control of the quarry. Standard Slag leased the property and railroad stock from the Minerals and Chemicals Corporation of America after Chemstone Dissolved. Standard Slag was made up of merged steel suppliers in eastern Ohio. The Company seen the quarry as an investment to produce the lower levels of limestone suitable for building and concrete production.

But the switch from fluxstone to pure aggregate was not going to be cheap.

One of the large problems faced with the company was the old Plant "D". Poor maintenance contributed with many problems with the plant. Standard Slag soon made modifications to the plant so that it could produce the lower dolomitic limestone. |

|

|

|

|

|

|

|

International Trucks with old easton wagons were a new sight in the quarry after the plant upgrades. |

|

|

|

|

|

Also the plant was in such decay that maintenance was nearly impossible to keep up with breakdowns. Immediately the company looked towards constructing a new plant to handle aggregate production and tonnage requirements. Designs for this new plant were completed by Siebert and Associates in Chicago. Early in 1964 the new plant called Plant "C", was erected and the project lasted till completion in 1967.

The new plant consisted of automated crushing and screening facilities, washing station, finished product stacking, and conveyor systems to the loading dock. |

|

|

|

|

|

|

|

A Bucyrus Erie 150B machine from the KIL&T days loads a tandom International truck in 1968 |

|

|

|

|

|

Operations in the quarry became steady in the middle section of the property close to the newly constructed plant. Soon a large working face and pit was formed in what used to be a high elevated area. All other areas of the quarry became abandoned, especially around the old Plant "D" area. The old Crusher "B" area which has been abandon became a dump area for scrap, and the Dryer Building was leased to a company called Chapin and Chapin. In the Dryer, it was used to manufacture gauge systems for automobiles for a short time. In the early 1980's the building was then leased to Lakeside Marine for boat storage. As for the Lakeside and Marblehead Railroad, it became extinct in late 1964. After this the remaining diesel locomotives and railroad became Standard Slags own industrial road. Another large change in the quarry was equipment. The once mighty Autocars were being replaced by International tractor trucks. The use of the Easton wagons continued, including purchasing of new and repairing of older units.

|

|

|

|

|

|

|

|

A Caterpiller 988 wheel loader dumps a load of shot rock into a well used 1948 Autocar truck. |

|

|

|

|

|

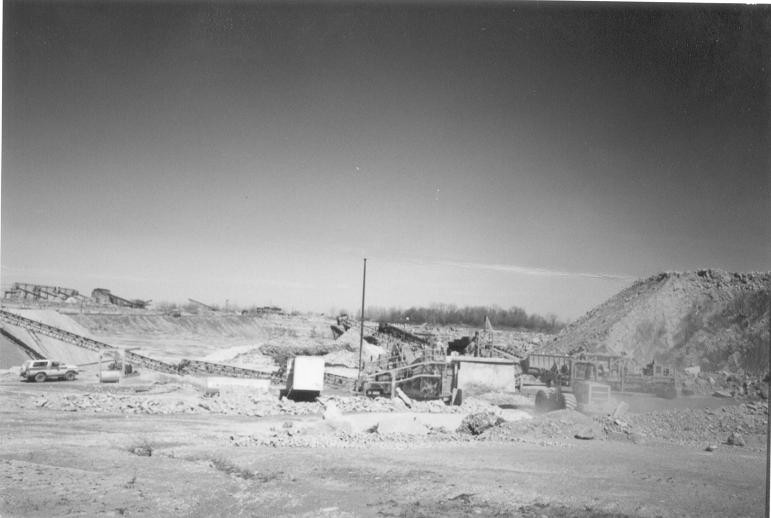

The International trucks were capable of towing in tandem two wagons compared to one by an Autocar. Standard Slag officials even experimented with the use of three units to one truck which turned out to be rough on the truck as it needed to climb the main haul road out of the pit. Also many of the Euclid R50's and 35's that were once used for loading the concrete bins at the loading dock were being used for shot rock hauling to the crusher. The three large Bucyrus Erie 150B shovels and the P&H shovel continued to do their work until the late 1970's. They were abandon due to more use of Caterpillar and Michigan front end loaders. The last remaining use of the Autocar trucks was reported around 1970. In the mid 1970's most of the International trucks were phased out for the larger Euclid and Caterpillar trucks. In the 1960's and 70's, the company filled many orders for road builder's throughout Ohio, and Michigan. These orders were being done by truck rather then railroad or lake shipping. In the early 1970's an auxillary portable plant was installed to help with production of base stone for construction. This plant was abandon in the 1980's. |

|

|

|

|

|

|

|

In the early 1970's this early portable plant was installed to process contractor aggregates. |

|

|

|

|

|

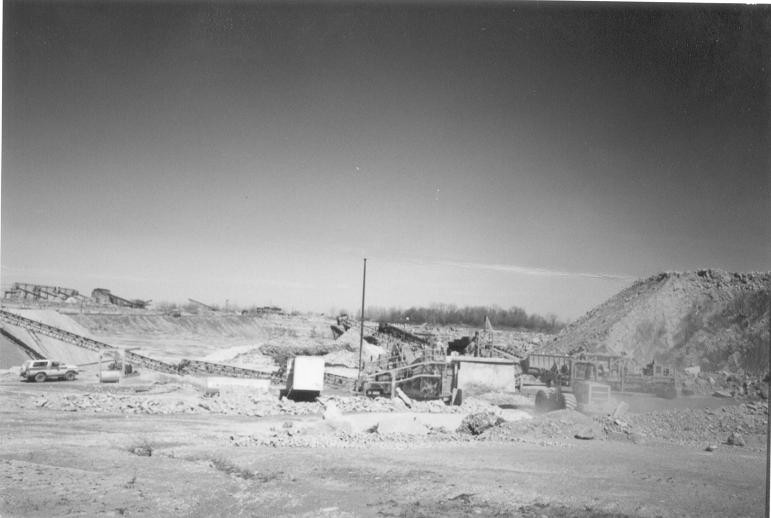

In 1980 as the railroad continued to decay, a large order of rip rap stone was taken. This shipment would be the last time the railroad would be used. Diesel engine 51 was taken out of stalemate and put back to work. A large track cleaning project was also underway since the road has not seen use for almost 10 years. Cleaning consisted as small brush removal and light track maintenance. This was done from the old enginehouse through Lakeside and along the main line to Danbury. A small portion of property near Plant "B" was cleared and quarried for the project. A clamshell crane loaded gondola cars with rip rap along the old main line curve. Then Number 51 would take the gondolas out to Danbury yard to await pickup. After the order was filled all rail movements ceased forever. Number 51 was put back into the enginehouse were at remained until it was scrapped in 1996. In the 1980's quarry operations remained steady in the central location. |

|

|

|

|

|

|

Standard Slag started to quarry deep, with two levels of working stone. |

|

|

|

|

|

|

In 1987 Standard Slag officials were looking into possibilities of installing a new automated crushing and screening plant. This plant would be of the outmost design and technology. The trend was movable primary crushing plants loaded with stone by front end loaders. This would make transporting shot rock from the face to the crusher by truck obsolete. Standard Slag began the project in 1989 but never seen it completed. That year the LaFarge Corporation of Reston, Virginia purchased Standard Slag and its holdings. The new division was created calling itself Standard LaFarge. |

|