Twincharged 20-Valve 4AGZE for AE86 Corolla

The page is rough... I'll be cleaning it up soon...

-updated 3-5-2005- water pipes+ ARP.

I put together a twincharged 16-valve 4AGZE about 5 years ago, and drove it for a couple of years. The turbo choked on a chunk of metal that broke off of my 1-way valve, so I pulled the engine out to repair the turbo.

I took the opportunity to do some modifications while the engine was out.

The car had good low-end torque with the supercharger, then the turbo would spool up and the power would steadily increase until the 8000 rpm rev limiter kicked in. Boost peaked around 12-14 psi. I was just to the point where I had exceeded the flow requirements of the 360cc injectors and had just upgraded to 440cc/min injectors.

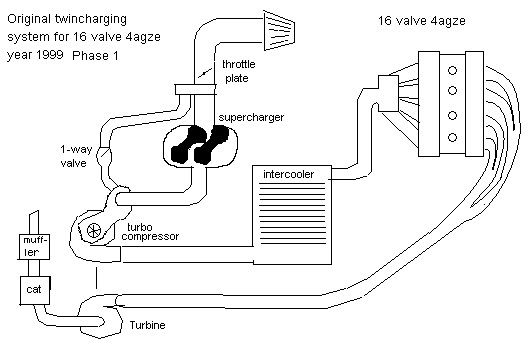

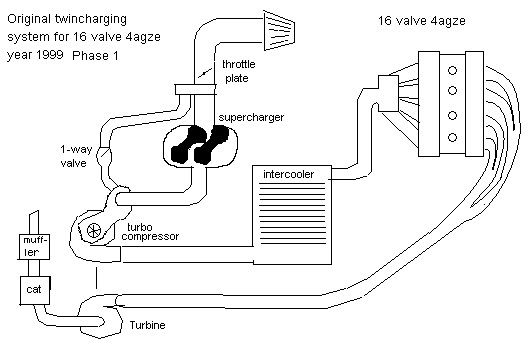

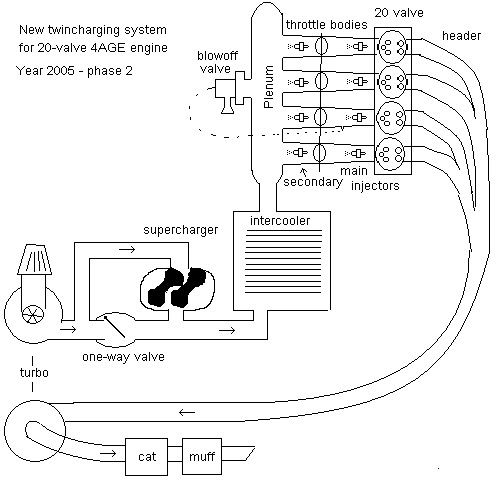

This is a diagram of how it was all connected together... The supercharger is a Toyota SC12, The turbo is a Garrett TO-3, 60 trim compressor and 48 trim turbine.

The engine was at a very mild state of tune with a 'safe' ignition timing map and enough fuel to keep the 02 gauge reading rich when in boost. When I took the engine apart, everything looked good, nothing overheated, plug tips fine, exhaust valve edges fine too. I will be a little more agressive with my tuning this time :)

I really wanted to change the intake manifold while the engine was out.. I'll tell you why..

The stock 4ac engine makes about 72 hp.

The Twincam 4age engine (bluetop) makes about 116 hp.

The US-spec 4agze makes about 140 hp at 8 psi with the help of a supercharger.

A Turbo 4age makes about 180 hp with at 8 psi of boost.

The 4agze makes about 75 hp without the supercharger.

(My setup provided a separate air path that went around the supercharger when it was turned off, I was watching intake manifold vacuum, and no the turbo was not a restriction to airflow.)

Why does the 4agze make less power than the 4age when manifold pressures are equal?

You lose 4% of your hp by reducing compression by 1 full point, but that doesn't account for much of the drop. There is no difference between the bluetop and the 4ag in the cams, head, ports, bore, stroke or displacement.

There is a big difference in the intake manifold though. The T-vis system lines up with each intake port and delivers high velocity air from a plenum in a straight line to the port (a good design). The 4agze has almost no plenum, very short runners with large cross-sections (low air velocity) that line up poorly with cyl #1 and #4. It's so bad that #1 runner meets the port at a 45 degree angle. So I wanted to replace the intake manifold. Just about anything would be better than what was there. But the reason that the stock intake manifold was so bad is that there isn't room for much else. The runner for cyl#1 can't be straight, it goes around the supercharger. I tried to install a T-vis manifold, but since it bends downwards away from the head, it interfered with the supercharger.. and I wasn't about to remove the supercharger! Same with the non- T-vis small-port manifold. Plus the throttle body was on the wrong end of the plenum and would need serious re-working to get it into the car.

I also wanted to get headwork done to the head, since it was nearing the 90,000 mile mark. Some 264 degree cams would have worked nicely.. But the cost.. Cams are about $300 each. A valve job and re-shimming would add a couple hundred bucks to the total.. so I could invest about $800 in the head, and I still had this awful manifold to deal with.

I knew about the 20-valve engines, but never seriously considered getting one because of the distributor location. I did not want a hole in my firewall. I was using the stock computer when I was putting the twincharger together the first time. I could not even find a 4agze computer, where would I find a J-spec 4agze computer that uses twin coilpacks to replace my distributor, and interface it to my american-spec wiring? No.. not an option. But now I am running Megasquirt as my fuel and spark controller, and IT DOES support a distributorless ignition system. It's the Ford EDIS system. They are plentiful here.

I looked at the intake system of the 20-valve and noticed that the intake ports are much higher on the head than the 16-valve. I also noticed that the intake throttle bodies are angled slightly upwards away from the head. From what I could see in pictures, it looked like the 20-valve intake system would clear the 4agze supercharger.

So, here's an engine that has a head that can be bolted to my existing block, it flows better than a re-worked 16-valve (or at least AS good). It has 250 degree cams with VVT (15 degree advance), has under-bucket shims, and has the coolest intake manifold ever.

Instead of spending $800+ on headwork, I purchased an entire low-mileage silvertop 20-valve from Japan for $500 and had it shipped to Phoenix.

Now I saved myself money, and ended up with a spare block, crank, rods, 16-valve head and I got rid of the horrible 4agze intake manifold at the same time!! Good deal.

Using the 20-valve head forces a few changes, but I think I can deal with them.

The timing belt is slightly longer when using the 20-valve head. I heard that a Porche 924 belt works. I have not tried this, and the belt that came with the engine looks almost new, so I will re-use it.

The bolt pattern on the exhaust side of the head is not exactly the same. One bolt is moved about 1/2 inch farther forward. I will have my header modified to fit.

The 20-valve water pump interferes with the supercharger, so the 4agze water pump will be used, also the thermostat housing is on the back of the head and probably won't fit in the car. I made a block-off plate with a circulation pipe and heater pipes. I will use the 4agze thermostat housing.. there will be pictures up here eventually.

The distributor will be gone! Typically the Ford EDIS ignition system works off of a 36-1 crank trigger wheel, but I don't want to use one because my front pulley already has an extra belt on it for the supercharger, and I also want power steering, and there isn't room for everything on the pulley, so I will use a 72-2 tooth trigger wheel on a cam sprocket instead of the crank. I have this working on my workbench, so it should work in the car.

I need to control the VVT solenoid with my ECU. I upgraded my megasquirt software to Megasquirt-Extra. I'm gonna have to add a LOT to my megasquirt page just to explain all of the new features in this software... I'm amazed. (and I don't amaze easily!) The Megasquirt will control Fuel, Spark (distributorless), Supercharger on/off, variable turbo boost control, knock sensor, wideband O2 sensor, fuel pump #1, fuel pump #2, injector bank #2, oh and VVT too! I could not have done this project without the Megasquirt Extra. Period.

I have to build a plenum to cover the four throttle bodies and hold 4 extra injectors. I will attempt to use carbon fiber and see how it works out. I will need a blowoff valve, because I am totally re-working my supercharger and turbo plumbing to make a blow-thru system.

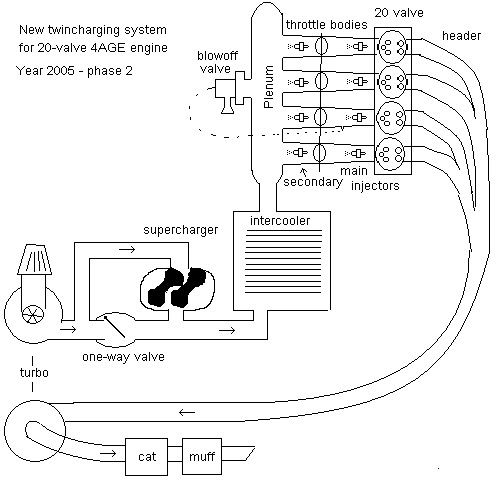

Here is a diagram of how the new plumbing will go. There are several advantages of this setup compared to the first setup.

1- The turbo inlet is open to air - there is no throttle plate before the turbo anymore. More air to the turbo is always good :)

2- The 1-way valve is a 2 inch valve instead of 1 1/4 on the old system.

3- The throttle plates are 3 inches from the intake valves, not 8 feet and on the other side of an intercooler like before. This will help throttle response and will stop idle fluctuations.

Other improvements not related to plumbing, just upgrades.

Changed engine blocks, now using low mileage 20-valve block with oil squirters.

New rings and bearings

Cometic metal head gasket

Wastegate actuator replaced with much stronger one!

Turbo inlet opened up and funnel-shaped.

Joel Britt's Quick-spool mod done to turbine section.

ARP head studs + main bolts.

Wideband O2 sensor

Knock sensor

Just when you thought I couldn't do any more to the engine.. I have another mod in store for it....

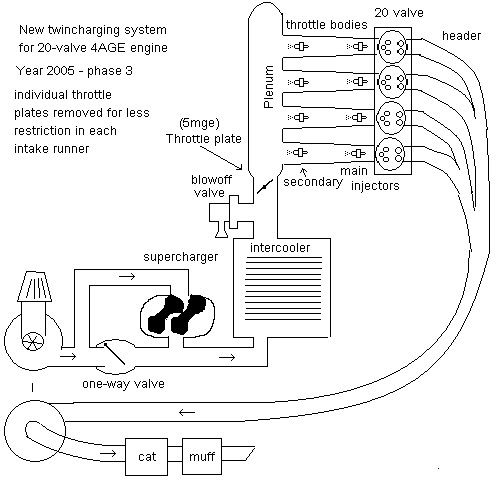

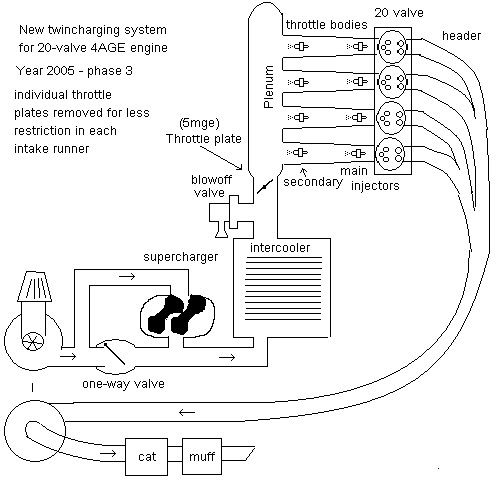

Eventually I will relocate the throttle plate. I will remove the throttle plate from each runner and use one throttle plate at the inlet to the plenum. This will clean up the airflow in each runner. It should be good for a few hp.

Home

20 valve page 2 - pictures

20 valve page 3 - it runs!