*

1.

Electron Emission

Electron emission is

actually the basic of tube working principal, it is defined as liberation

of free electron from a surface of a substance caused by the externak energy

transfered to the electrons.

Electron emission tends to occur on metal,

because metal is a substance with much free electron in between its molecul.

Nucleous attracting force does not strong enough to put the electron standstill.

Every time the free electrons move around from

one molecul to another but it can't leave out from metal

surface. In order to emit from the metal surface these free electrons

require additional external energy. The amount of outside energy

require by electron to emit from the metal surface is known as work

fuction. The work function ussually defined in elctron volt (eV) unit.

The additional external energy require by

the electron to emit from the metal surface could come from few sources

such as heat enery, energy stored in the electron field, light energy or

kinetic energy.

Accordingly there are following

four method of obtaining electron emission from the metal surface.

1.1 Thermionic emission

1.2 Field emission

1.3 Secondary emission

1.4 Photovoltaic emission

1.1 Thermionic Emission

In this method the additional

energy come to the electron in the from of heat energy, by the electrons

the energy trasnfered into kinetic energy. As the kinetic energy

of electron increase its movement become uncertain and then finally there

will be electrons that leave out from the metal surface.

The substance where the electrons

emit from, is known as emiter or cathode.

In case of vacum tube it is preferably to

call as cathode. And the substance that receive electron is known as anode

or plate.

With regard to thermionic emission there

are two type of cathode :

a) Direct Heated Cathode ( in short

DHC)

b) Indirect Heated Cathode ( is short IHC)

The simplified figure of DHC seen of Figure

2. In this type of cathode, both heater current and also emited electrons

come from it.

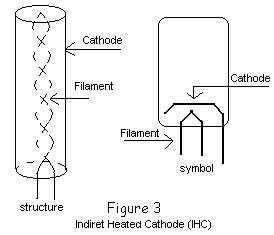

And the simplified structure of IHC seen

of Figure 3.

Heater current does not flow through the

cathode, but through the heater element that is known as filament. The

heat energy from filament conduct into cathode through insulator placed

between cathode and heater.

Material used for cathode must have the following

properties :

a. Low work function, so that the

electron emission could accur using only small

amount of energy

b. High melting point, as the thermionic

emission occurs at high temperature so the

substance used ascathode

must have high melting point

C. High mechanical strenght, Substances

used as cathode must have strong

mechanical strenght to

withstand the bombardment of positive ions.

In vacum tube no matter

how crefull the evacuation there

still always present

of gas molecul which

may be in the form of ion by impact with electron. Under

the influence

of electric field these positive ions will strike the cathode and if

the high voltage is being

used, the cathode is subject to considerable

bombardment and can be damaged.

Commonly used Thermionic Cathode

The high temperature

needed for satisfactory thermionic emission in vacum tubes limit the number

of suitable emitters to such substances as tungsteen, thoriated tungsten

and certain oxide coated metals

a. Tungsteen

It was the earliest material

used as cathode and has slightly higher work

function (4.52 eV). Theimportant

factors in its favor are : high melting point

(3650 degress K), greater mechanical

strenght and longer life. The

disadvantages are : high operating

temperature(2500 degrees K), high work

function and low emission efficiency.

Therefore, it is used in application

involving voltage exceeding

5kV, example XRay tubes.

b. Thoriated Tungsten

A mixture of two metals

may have lower work function than either of pure

metals alone. Thus a

tungsteen emitter with a small quantity of thorium has a

work function 2.63 eV

compared with 3.4 eV for thorium

and 4.52eV for

tungsteen. At the same time

thoriated tungsteen provides emission at

lower

temperature (1700 degress K)

and require smaller amount of heat energy.

c. Oxide-Coated Cathode

This type of cathode

consist of nickle ribbon coated with barium and strontium

oxide. The oxide

coated cathode has low work function (1.1 eV), operate at

comparatively low temperature

(750 degrees K) and also

has high emission

efficiency. However it

can't withstand high voltage,

therefore it is mostly

used in applicaation

where voltages involved do not exceed 1000 V.

In this type of emission additional

energy come in the form of electric field. When a conductor put in a place

very close to high voltage conductor, the electric field from the

conductor will exert attractive force on the free electron

in metal. If the positive field is big enough the free electron will succeed

in ovecoming restraining of the metal surface and it will emit from

the metal surface.

Very intense electrid field is required

to produce field emission. Ussually a voltage of the order of a million

volts percentimetre distance between the emitting surface and the positive

conductor is neccesarry to cause field emission. Field emisson can

be obtained at temperature much lower than required for thermionic emission

and therefore it is also sometimes called as cold cathode emission

or auto electronic emission.

Electron emission from a metalic surface by the bombardment of high speed electrons or other particles is known as secondary emission. When high speed electrons suddenly strike a metalic surface, they may give some or all of their kinetic energy to the free electrons in metal. If the energy of the striking electrons is sufficient, the free electron will escape from the metal surface and this phenomenom called as Secondary Emission. The principle of secondary emission describe on Figure 5. A glass envelope consisting electron source, cathode and plate. When electrons from electron source strike cathode they will knock out secondary electron from cathode which are attracted to plate by positive voltage from plate. The effect of secondary emission are very undesirable in many electron device for example in tetrode where secondary emission is responsible for negative resistance.

In this type of emission the additional energy

come to cathode by photons. When a beam of light strike the surface of

cathode the energy from photons will be transfered from the photons to

free electron within the cathode. If the energy from photons is greater

than the metal work function the free electron will knock out from the

cathode surface. The emitted electron called as photo electron. The amount

of photo electron depend of the light intensity.

We've just finished with electron

emission and hopefully you enjoy the discussion.

Now we're going to talk about

vacum tube and its working principle.

Vacuum Tube

An electric device which the flow of electron

is through a vacum is known as Vacum Tube.

There are several ways of classifying vacum

tubes according to the number of electrode. Vacum tube are classified as

under :

- Vacum Diode

- Vacum Triode

- Vacum Tetrode

- Vacum Pentode