|

|

|

MOCK EXAMINATION 1999 SECONDARY TWO EXPRESS DESIGN AND TECHNOLOGY

|

| Name : | Time : 1hour 30 minutes | |

| Class : | Marks : /100 |

|

INSTRUCTIONS TO CANDIDATES This paper consists of three sections. You should write your answers to Questions 1 to 7 in the spaces provided. Question 8(a) should be done in the isometric grid paper and Question 8(b) in the square grid paper. You are advised to spend not more than 20 minutes on Section A 20 minutes on Section B 50 minutes on Section C. This paper consists of 8 printed pages. |

|

|

Section A (30 marks) You are advised to spend not more than 20 minutes on this part. Attempt all questions. 1. Name the following tools and state their uses: |

| Name of tool :auger bit Uses : used with a ratchet brace for cutting large holes in wood. |

||

|

Name of tool : curved snips Uses : used for cutting internal curved edges on sheet metals. |

|

|

Name of tool : protractor Uses: Used with a scriber to marks lines that are at an angle to the datum edge of a metal workpiece or to text the angle of a bevel in a workpiece. |

|

|

Name of tool : rasp Uses: Use to shape wood. |

|

2. Fill in the blanks with suitable words. a.In plain sawing, the log is cut into planks by parallel saw cuts. 3. Suggest a suitable material for making each of the following products: (6 marks) e.g. raffia polypropylene a. garden bench chengal (1) b. air conditioning duct zinc (1) c. soft solder lead(1) d. cooking pot stainless steel (1) e .sculpture bronze (1) f. barrel bolt brass (1) 4. Answer the following questions in complete sentences. a. List two advantages and two disadvantages of plastics. Advantages : ability to be coloured,ability to take complex shapes,ability to be softened with heat,withstand shock,flexibility or corrosion resistance. Disadvantages : it is not as strong as metals and most plastics do not have a very high resistance to heat. b. Suggest some suitable materials for making templates. Why are they suitable? c. Name the tool that is used test the angle of a bevel. d. Give an advantage of knock-down furniture. e. Why is a pair of plastics gloves not suitable for working with hot acrylic. f. Explain why it is sometimes necessary to heat up a metal workpiece before bending is carried out.

Section B (20 marks) You are advised to spend not more than 20 minutes on this part. Attempt all questions. Answer the following questions in complete sentences 5. Describe how you would make an acrylic photo holder by filling in the blanks under the four steps given below: Step 1 : Marking out - Describe how you would mark out on the acrylic. Step 2 : Cutting and Shaping - Describe how you would cut and shape the acrylic. Step 3 : Finishing - Describe how you would finish. Step 4 : Thermoforming - Describe how you would thermoform and shape the acrylic. 6. The steps in joining two metal parts are shown below. Fill in the blanks to describe how the two metal parts are joined together. (10) |

|

|

|

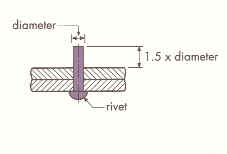

| 1.Drill a hole through both pieces of metal. | 4.Use the flat face of hammer to swell the end of the rivet. | |

|

|

|

| 2. Cut rivet to correct length. | 5.Use ball pein hammer to hsape the head of the rivet. | |

|

|

|

| 3. Press the two parts together with a rivet set. | 6. Form the rivet head using a rivet snap. |

|

Section C (50 marks) 7. You have been asked to design a small wooden shoe box. Any two : safety, appearance, materials and cost. b. What type of wood would you use to make the shoe box? (2) Pine c. Give one reason for your choice of wood. (2) Easy to work with. d. Suggest two types of joints you would use to assemble the parts. (4) finger joint for the carcase and through housing joint for the shelf. (similar answers will also be accepted). e. In the space provided, sketch a 3-dimensional view of the shoe box. (5) Show clearly the joints that you have chosen.

8. The figure shows a geometrical solid. a. Draw an isometric view of the solid on the isometric grid paper. (15 ) b. On the square grid paper, draw the Front Elevation, End Elevation and Plan of the solid as viewed from the direction of the arrows. (20) All dimensions are in millimetres. Do not dimension your drawings.

END-OF-PAPER

|