A source of light

is essential for campers, especially at night. The pressure lamp

is 1 main source of light in the NPCC campsite. Therefore, it is

neccessary for cadets and instructors to familiarize themselves

with the basic knowledge of lighting pressure lamps.

- Safety

Precautions

- Ensure

that no spirit or kerosene is placed near to the

pressure lamp when lighting.

- No

kerosene should be stored in the kerosene

container when the pressure lamp is under storage

for a long time.

- Do not

leave the pressure lamp in the open when they are

still hot.

- Do not

store pressure lamps when they are still hot.

- Do not

touch the mixer flame assembly directly after

distinguishing the pressure lamp as it is

extremely hot.

- Discontinue

pumping air into the pressure lamp once the

needle in the pressure gauge is near the red line

on the pressure meter.

- No

lighted pressure lamp is allowed in the tents.

- Do not

use methylated spirit to clean the glass chimney

even though it is easier to remove the soot with

it. Use newspaper to clean the glass chimney

instead.

- Do not

touch the mantle once it is burning.

- Never

pour kerosene into the kerosene container through

the pump opening.

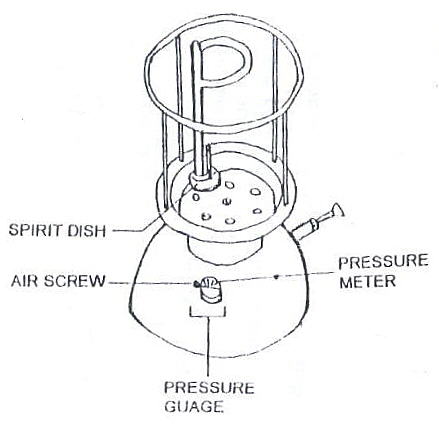

- Pre-lighting

Checks

- Check

whether the pressure lamp is in good working

condition. Do this by first tightening the air

screw and then by pumping in air. Release the air

screw to check whether pressure has build up in

the kerosene container.

- If the

pressure gauge shows no change or a decrease in

the air pressure, unscrew the pressure gauge to

check whether the rubber seal is in good working

condition. If the rubber seal is worn out or

missing, replace a new one.

- Remove

the mixer flame assembly to check that the

cleansing needle is not worn out. This can be

achieved by turning the regulator upwards so that

you can feel the presence of the cleansing needle

with your fingers.

- Lighting

Procedure

Stage

1

- Free

the ventilator cap by loosening the 2 side nuts

attached to the handle of the pressure lamp.

Stage 2

- Remove

the ventilator cap and lift out the mixer flame

assembly.

Stage 3

- Unscrew

and remove the pressure gauge, then till the

kerosene container with kerosene using a funnel.

(Do not loosen the rubber seal in the pressure

gauge.)

Stage 4

- Pour

in the kerosene until the kerosene container is

between half to three-quarters full.

- Screw

back the pressure gauge tightly.

- Remember

to tighten the air screw as well.

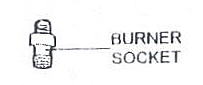

Stage 5

- Tie

the mantle to the burner socket. (Ensure that the

burner socket is firmly fixed to the mixer flame

assembly.)

- Excess

string from the mantle may be cut away.

Stage 6

- Replace

the mixer flame assembly

Stage 7

- Fill

the spirit dish with methylated spirit through a

small opening beside the regulator.

Stage 8

- Light

the methylated spirit with the regulator pointing

upwards.

- Wait

for the mantle to be heated up.

- When

there is sufficient heat, you will see a red glow

in the mantle.

Stage 9

- Start

pumping in between 50-60 strokes.

- Turn

the regulator until the mantle brightens.

- At

intervals of 3 to 4 hours, increase the pressure

to substain the glow of the lamp.

Distinguishing

Procedure

Loosen

the air screw slightly to release pressure in the

kerosene container. The pressure lamp will distinguish

after there is no more pressure in the kerosene container

to supply the mixer flame assembly with kerosene.

- Care and

Maintenance

- Never

place the base of the mixer flame assembly

directly on the ground to avoid damaging the

burner socket.

- Turn

the regulator downwards when replacing the mixer

flame assembly to avoid damaging the cleansing

needle.

- Ensure

that the glass chimney does not come in contact

with water when it is still hot to prevent the

glass chimney from cracking.

- Use

the proper tool of the right size when

dismantling or assembling the pressure lamp. A

spanner with a larger gauge when required will

damage the hexagonal shape of the joints.

- Filter

all kerosene before pouring them into the

kerosene container. Dirty kerosene will choke the

channels of the pressure lamp.

- Check

the washers periodically to ensure that they are

firmly embedded in their positions.

- Replace

the leather washer in the air pump if it has been

worn off.

Simple Repairs to

the Pressure Lamp

Blockage of

kerosene passage - Dismantle the passage tube and use an air jet

to blow off the dirt or to a slight extent. Light the lamp and

turn the regulator quickly to the left and right. The cleansing

needle will force the dirt out of the nipple.

Needle too short -

unable to block the nipple - Dismantle the kerosene passage and

remove the cleansing rod. Adjust the nut at the base of the

cleansing rod respectively.

Leakage

- Determine the leaking part. Dismantle the lamp except for the

kerosene passage. Turn the regulator upwards to block out the

nipple and tighten all remaining parts. Start pumping until the

sign of kerosene shows. If the leakage comes from a joint,

tighten it. You may need some soldering plaster if the screw

threads are worn off.

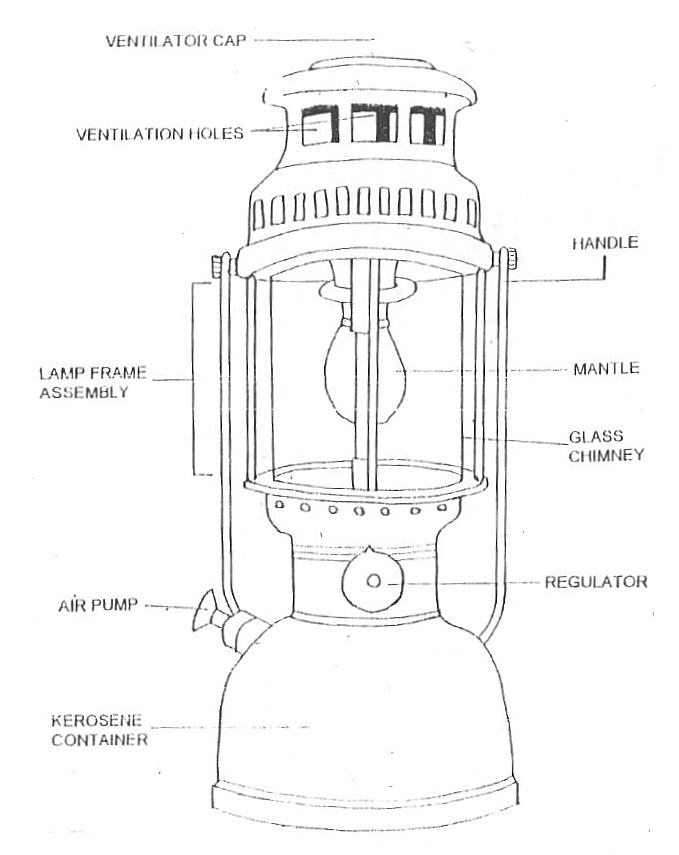

Parts of the

Pressure Lamp

BACK TO

HOMEPAGE