Twin Spark engines

Double ignition

The Alfa Romeo Twin Spark technology was developed by Alfa to enable it to achieve a higher power output from its engines and to enable their cars to comply with EC Stage 2 exhaust emissions and noise standards.

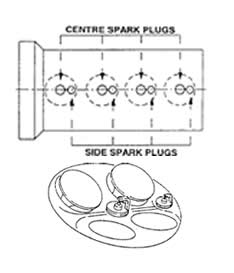

The Twin Spark name comes from the fact that there are two spark plugs per cylinder. The second small spark helps to reduce harmful emissions and protects the three-way catalytic converter by ensuring that less unburnt fuel should reach it.

The Twin Spark technology was first introduced

in 1985, when the old twin-cam engine from the Alfa 75 was redesigned

to incorporate two spark plugs per cylinder (as Alfa had done in

the past in various race engines). All Twin Spark engines are 4

'in line' and have been developed with 8 or 16 valves. All cars

featuring the Twin Spark engines since the Alfa Romeo 155 use the

16 valves ones. Porsche and Mercedes have also developed engines

with two spark plugs per cylinder, but Alfa Romeo is the only one

to put two spark plugs and 4 valves per cylinder. |

All Twin Spark engines available on the Alfa 145/6 use a 10mm diameter and a 14mm diameter longlife platinum spark plug per cylinder.

|

|

These engines also incorporate two devices to improve the performance and the fuel management efficiency: the Camshaft Phase Variator and the variable geometry intake systems (the second one only available for 1.8 and 2.0 versions).

Camshaft Phase Variator

The valve variable timing system allows the camshaft to be shifted into two different angular positions in order to modify the intake valve opening durations.

The Phase Variator is an electro-hydraulic actuator controlled by the injection system that adjusts the angle (or phase) of the air intake camshaft to allow the valve open and close time to advance when the engine RPM exceeds 4300. A similar process is used by Honda and Toyota on their VTEC and VVT-i engines.

Valve timing actuator logic is predetermined so that overlap - that fraction of the engine's operating cycle when both the exhaust and the intake valves are open simultaneously - is shorter at low rpms and with lighter loads, and longer at higher engine speeds when extra power is required.

More information about the Timing Variator

Variable geometry intake system

This device is managed electronically by the injection system and assures the optimal cylinder air filling at all rpm levels. The intake manifold contains two plastic (nylon reinforced by fiberglass) ducts and use the longer one (560 mm) at low rpms and the shorter one (380 mm) at higher rpms.

This system was presented on the 1.8 and 2.0 TS versions of the Alfa Romeo 156 and adopted at the Alfa 145/146 on 1999. This system gives 4-5 bhp increase in top power and a reduction of 500 rpm at peak torque.

The notable effect that these devices have is that the engine will surge powerfully forward on hitting the 4300 RPM mark, right up to the RPM limiter. On the Alfa 145/6 TS the red line is at 7.000 rpm and the fuel cut-off at about 7.300 rpm.

Another technical features

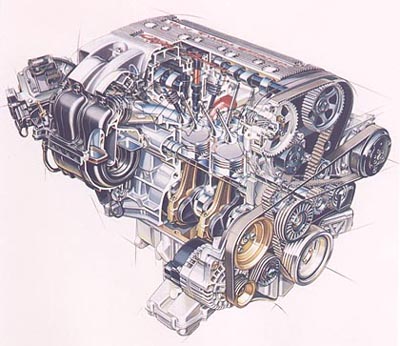

Cylinder heads with hemispherical combustion chambers that ensures a fast, wide flame front when the air-fuel mixture is ignited.

Cylinder head with a narrow 47 degree V-shaped valve arrangement.

Twin overhead camshafts and four valves per cylinder operated directly by hydraulic tappets.

A lubrication system which uses specially designed jets to spray oil onto the piston crowns, ensuring highly effective cooling.

Automatic belt tensioners which, theoretically, free the engine from frequent maintenance.

Twin balancer shafts system that minimizes the vibration normally associated with inline-4 engines (only for the 2.0 version).

|

|

Common faults

Timing Belts

Alfa originally recommends changing cambelts at 120.000 Km but after some premature failures they unofficially recommends changing it at 80.000 km or five years, together with the tensioners. In some countries they recommend changing it every three years.

Phase Variator

Another common fault is the "diesel-noise" from the Twin Spark engines. It's a typical failure of the Phase Variator that produce loss of top power, less power under 3.000 rpm and higher fuel consumption. It also produces the typical "diesel-noise".

The "diesel-noise" will in the beginning last only a few seconds after turning your key to start the engine. But it will last longer and longer. There should be no problem driving with this, you will not damage anything, but it should be fixed together with the cambelt change.

Erratic idle speed

The idle speed of a Twin Spark engine is about 900 rpm. A common fault is that the revolutions ups and down between 500 and 1500 rpm while stays at idle. The cause of this problem could be a faulty idle speed motor or some dirt at the butterfly-valve.

Engine powerloss, missfire

Sometimes, in cold starts, the car seems to have a bit of a problem pulling away but a few seconds later it will be OK. After a couple of minutes things seem fine. This problem is difficult to fix because it could be caused by several reasons: fouled injector, faulty lambda sensor, air mass meter or water temperature sensor, dirty spark plugs, . . .

High oil consumption

It is recommended to check usually the engine oil level because some Twin Spark engines have high oil consumption.

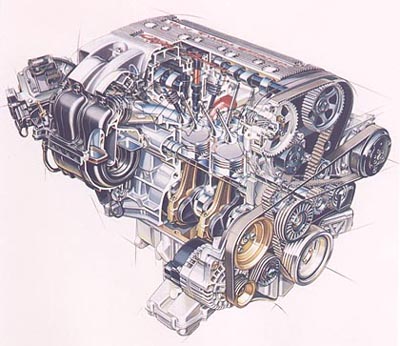

Engine diagrams

|

|

|||||||

|

|

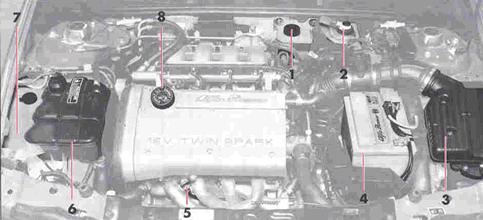

| 1 Hydraulic power steering fluid. |

| 2 Brake and clutch fluid. |

| 3 Air filter. |

| 4 Battery. |

| 5 Oil level control. |

| 6 Cooling fluid. |

| 7 Windshield wiper fluid. |

| 8 Engine oil filling. |

| Alfa Romeo 146 Junior WebSite ( http://www.oocities.org/alfa146website ) |