What you need:

A piece of threaded rod of aproppriate size,

two nuts and a piece of scrap PCB, G10 or similar.

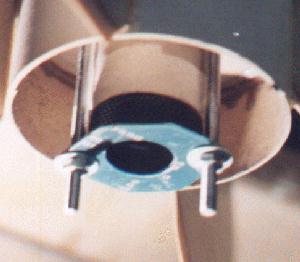

How it fits together

Cut two pieces of appropriate length from the threaded rod and make a retainer plate from the PCB/G10/whatever material.

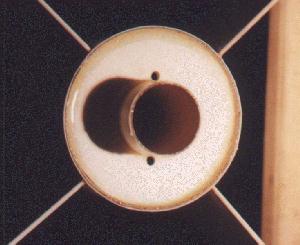

A test fit should look like this.

Prepare the rocket

Drill two holes for the threaded rod into the lower centering ring.

..now test fit the parts...

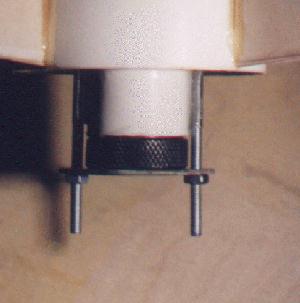

Now glue it!

First protect your motor or reload casing with some tape. Then pour some epoxy (15 to 30min) through the holes in the CR, fit the holder, fix it with some tape and add generous fillets to the bolts. Rotate the rocket until the epoxy sets.

There it is: positive motor retention!