TECHNOLOGY UPDATE

From ROAD & TRACK, January 1998 (US car-magazine)

IN THE EARLY days of emissions controls, we ran a droll cartoonshowing

a clean air car sucking in smog and emitting crystal-clear exhaust.

Well, guess what? Honda's ZLEV technology, announced at the 1997 Tokyo

Motor Show, is very much along these lines. The letters stand for Zero-Level

Emissions Vehicle; and, to avoid possible confusion in our

clean-air alphabet soup, here's Honda's definition: A ZLEV's emissions

are the same as those emitted by a state-of-the-art electric utility when

the latter is producing the power to propel an electric vehicle the same

distance.

The relevant pollutants are carbon monoxide (CO), the nitrogen

oxides (collectively, NOx) and the non-methane organic gases (NMOG). These

last, by the way, are the hydrocarbons (collectively, HC) that actually

contribute to smog.

To put ZLEV numbers in perspective, they're typically less than 0.10

of Ultra Low Emissions Vehicle standards, hitherto the lowest promulgated

for internal combustion engines. What's more, this is the first time I've

seen a quantification of emissions from "Zero" Emissions Vehicles, or ZEVs,

when the remote emissions of the electric utility are factored in -- as,

of course, they should be.

That is, as I noted a while back, ZEVs would be more logically called

REVs, Remote Emissions Vehicles. On the other hand, our clean-air alphabet

soup recipe is complex enough as it is, so I rather doubt my suggestion

will catch on.

Honda dernonstrated this new technology in a most astounding manner.

I got to drive one of the ZLEV cars at its Tochigi, Japan, R&D facility.

Its operaüon was utterly transparent, with exemplary driveability

and good power. In particular, even on light throttle, 1 sensed no lean-burn

hunting whatsoever. A perfectly normal Honda.

Then the car was brought into the emissions lab, hooked to the analyzer

and run through the final portion of the U.S. Federal Test Procedure.

Its NMOG for instance, were around 0.5 parts per million; sure enough,

equivalent to 0.10 ULEV level. Next, engineers removed the sensor from

the ZLEV's tailpipe and exposed it to the lab's ambient air. The NMOG level

in the lab measured around 1.6 ppm; quite clean, really; about half

of a typical Los Angeles ambient reading -- but also more than three tinies

dirtier than the ZLEV's exhaust.

Literally, ZLEV operation imitates that R&T cartoon in cleansing

the air.

ZLEV technology is an iteration of Honda's existing ULEV practice.

A 32-bit Electronic Control Unit gives extremely precise control

of the air/fuel ratio. A series of catalytic converters operate at especially

high efficiency. And Honda's VTEC variable valve timing hardware plays

an important role as well.

lt's a three-stage strategy. First, in cold start, VTEC induces a marked

swirl of the incoming charge to reduce unburned HC. Any HC that is

produced gets absorbed downstream on one layer of an innovative dual-bed

catalyst. Second, during warmup, the converter residing immediately next

to the exhaust manifold quickly reaches its operating temperature. In the

meantime, farther downstream, the HC is "de-absorbed" and treated as the

threeway portion of the dual-bed catalyst heats up. The gases then travel

into an Electrically Heated Catalyst directly downstream of the dual-layer

device. The EHC's operation is optimized for highly efficient treatment

of this remaining HC.

Third, in normal Operation, the advanced 32-bit Electronic Control

Unit offers two benefits in engine management. Emissions are reduced at

the source through a more stable combustion process. And an extremely precise

control of the air/fuel ratio provides "feed gases" that keep the converters

operating in their most efficient range.

It's noteworthy that Honda's ZLEV technology is essentially evolutionary,

not particularly radica1. Also, this is an ordinary car burning gasoline,

not some exotic alternate fuel.

About two years ago, I drove a prototype of Honda's ULEV Accord. It's

now available in selected U.S. markets. Expect a similar lead time for

Honda's ZLEV

IMA, an electronic turbo

THE SECOND MAJOR innovation shown by Honda at Tokyo was its IMA, Integrated

Motor Assist. This hybrid powerplant combines a 1.0 litre 3-cylinder VTEC

Gasoline Direct Injection engine, an electric motor/generator linked to

in ultracapacitor, and a continuously variable drive.

It's a parallel hybrid, with each power source contributing to propulsion

on demand; this, as opposed to a series hybrid, where one power source

feeds the other, which, in turn, drives the wheels.

In fact, think of the IMA as a small displacement gasoline engine augmented

by electric supercharging.

An ultracapacitor is a largish

condenser, an electrical device storing its charge between internal plates.

The IMA´s ultracapacitor array is about the volume of a Suitcase

-- decidedly smaller and lighter than any EV battery pack. On the other

hand, it's purely for intermittent use: IMA's fully charged gizmo offers

perhaps 13 seconds of boosted operation.

The IMA's high efficiency comes from several interacting strategies.

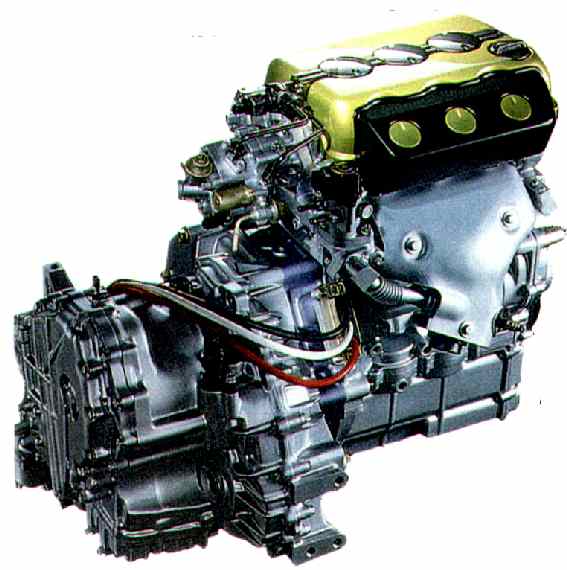

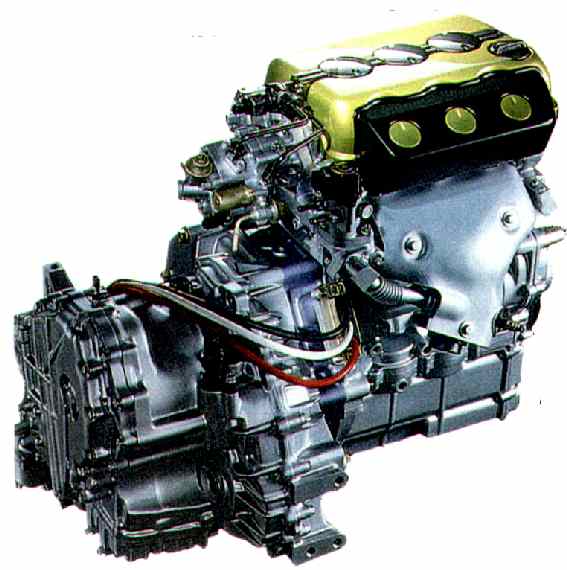

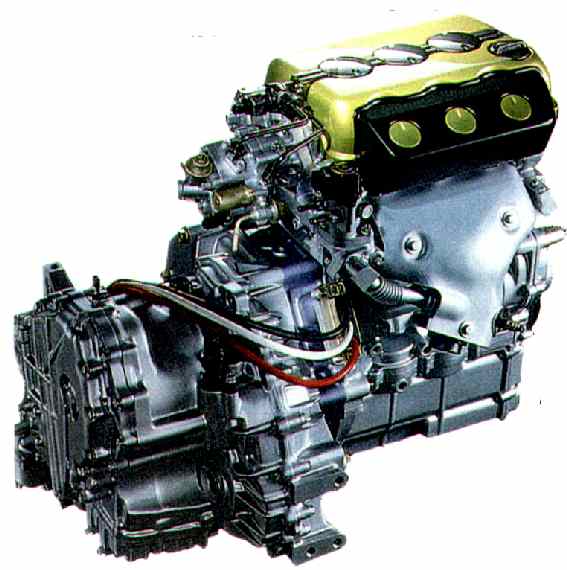

Honda's integrated Motor Assist sandwiches a high torque electric

motor between its direct-injection gasoline engine and CVT gearbox.

The result is 70 mpg in Japan city mode testing.

Honda's integrated Motor Assist sandwiches a high torque electric

motor between its direct-injection gasoline engine and CVT gearbox.

The result is 70 mpg in Japan city mode testing.

First, under light load, the gasoline engine and CVT operate in regimes

of GDI lean-burn high efficiency. (For details of Gasoline Direct Injection,

see "Technology Update: The Last Internal-Combustion Engine?" December

1997.) VTEC promotes this light-load combustion with high-swirl-inducing

valve timing. Also, the small displacement of the IMA engine translates

into reduced frictional and pumping losses.

Second, gradual demands for power are met essentially by the gasoline

engine alone, its VTEC valve hardware changing over to optimize engine

performance at higher revs.

Third, to invoke immediate power, IMA calls on the ultracapacitor.

Its charge is routed to the electric motor/generator nestled between the

engine and CVT. This DC brushless motor is derived from Honda EV Plus technology.

Also, its controller is programmed to invoke a subtle reverse torque on

the gasoline engine's output, thus reducing torque fluctuation of its configuration.

Fourth, in braking, the motor/generator operates regeneratively, charging

the ultracapacitor for its next boost.

Neat, eh?

What's more, all this hybrid activity happens essentially transparently

to the driver. I had an opportunity to tool around Tochigi in an IMA powered

Honda Life city car and can report that an "Assist" light on the dash was

the only way I could sense any transition from gasoline power to ultracapacitor

boost.

Honda says the basic gasoline engine produces some 70-80 bhp, with

the electric motor contributing another 50. The entire package weighs

about 110lb. more than a conventional 1.5-liter powerplant, this

latter actually yielding somewhat less performance. Also, the IMA's control

strategy is designed to optimise the high rpm power of the VTEC GDI engine

with the high torque available from an electric motor on demand.

An important benefit is IMA fuel efficiency (and hence its reduced

CO2 production). Fuel economy is said to be better than 70 mpg on the Japanese

city mode test. The IMA package is part of Honda's J-VX sports coupe exhibited

at Tokyo (see Ampersand). This hybrid technology is likely to appear on

the roads of Japan within two to three years and here as well in time.

Ampersand:

HONDA JV-X

At Honda, the theme was "Small is Smart." And this 2+2 JV-X concept

car looks smart indeed, sort of a CRX for the next millenium. Beneath the

hood of this California styled front driver is a totally new power unit,

a lightweight, clean-burning, direct-injected, VTEC-aided 1.0-litre inline-3

that has an ultrathin motor/generator mounted between it and the continuously

variable transmission. This motor/generator serves as an extra power source

for the JV-X when it's accelerating. Honda says that, thanks to IMA (the

Integrated Motor Assist system), the JV-X accelerates like it has a 1.5-litre

engine rather than a 1.0.

IMA also helps make the JV-X's fuel economy excellent, a heady

70 mpg. Under braking and deceleration, the motor/generator transforms

kinetic energy into electric power. Of note, the electricity is stored

in (and quickly released from) huge capacitors, which weigh 66 lb.

Power capacitors (Ultracapacitors) from:

HONDA JV-X

At Honda, the theme was "Small is Smart." And this 2+2 JV-X concept

car looks smart indeed, sort of a CRX for the next millenium. Beneath the

hood of this California styled front driver is a totally new power unit,

a lightweight, clean-burning, direct-injected, VTEC-aided 1.0-litre inline-3

that has an ultrathin motor/generator mounted between it and the continuously

variable transmission. This motor/generator serves as an extra power source

for the JV-X when it's accelerating. Honda says that, thanks to IMA (the

Integrated Motor Assist system), the JV-X accelerates like it has a 1.5-litre

engine rather than a 1.0.

IMA also helps make the JV-X's fuel economy excellent, a heady

70 mpg. Under braking and deceleration, the motor/generator transforms

kinetic energy into electric power. Of note, the electricity is stored

in (and quickly released from) huge capacitors, which weigh 66 lb.

Power capacitors (Ultracapacitors) from:

Maxwell Technologies

Energy Products

4949 Greencraig Lane

San Diego, CA 92123

Tel 619-496-4123

Fax 619-576-7672

email: powercache@maxwell.com

http://www.powercache.com