Stereo Video Digitizer

The stereo video digitizer will

accept video input from 2 PAL CCD video camera. It digitizes the video

and display both the video sources on a PC monitor. My digitizer support

only greyscale video.

A software has been written

to display the digitized video on a PC monitor. There are 2 versions of

the sofware:

winepp standard

version, for still image capture

wineppx utilises

the Direct X 6.1 library. Requires Direct X 6.1 installed.

This is actually my university

thesis project. For simplicity, I convert the chapter 3 of my thesis into

this page, so all the pet label in this page start with 3.x. Please bear

with it. You can download my thesis

in MS Word format.( 1.1 MB)

The Hardware and Theory Description

In this chapter, the entire stereo video digitizer hardware is broken into

subtopics and explained. There is also a part on building the hardware

board—schematic design and PCB fabrication.

System Description

Figure 3.1 System Block Diagram

Basically, this project can

be separated into several main functional blocks. Each of these blocks

perform a specific task, which would be explained in the later section.

As a stereo video signal

(dual video sources) goes into stereo video digitiser, only one channel

is being chosen at one time by the Video Multiplexor. A video amplifier

will also amplify the video signal. The amplified video signal will

be route to an analogue to digital converter (ADC) to be converted into

digital raw data.

A Synchronization Separation

and video timing circuit is aimed to generate a suitable sampling clock

to drive the Analogue To Digital Converter (ADC), as well as the write

clock into the digital data storage.

Having digitise the analogue

video signal, it is stored in a digital data storage block. The data can

then be sent to a PC through the parallel port in Enhanced Parallel Port

(EPP) mode.

The control logic block

is meant for doing the handshaking signals required by the EPP protocol.

Video Input Multiplexing And Amplification

The CCD camera used in this

project is a PAL standard camera. Its output range from 0 to 1V.

As shown in figure 3.2,

the digitizer has 2 BNC header as input for 2 CCD cameras. The signal is

terminated using a 75W resistor, and fed into the MAX4313 video amplifier,

which will be explained in section 3.3.2.

Several ceramic capacitors

are used to decouple the voltage source to ground. This is for noise suppression

purpose on the power source, which will be explained in section 3.4.

Figure 3.2 Video Input, Multiplexing and Amplification

Both the video signals will

then be fed into a video-multiplexing amplifier, the MAX4313. Although

the stereo video digitizer has two video-input channels, only one channel

is routed to the Analogue to Digital Converter at one time. By using the

multiplexing feature of the MAX4313, only one video channel is selected

each time.

MAX4313 also provides a

fixed gain of +2V/V. This device has a 40ns channel switching time, low

10mVp-p switching transient, and a 150MHz –3dB bandwidth, making it ideal

for video switching application.

Synchronization Signal Separation

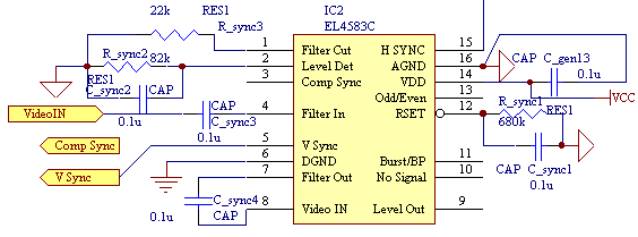

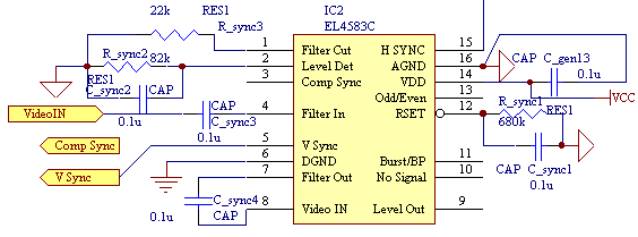

Figure 3.3 Sync Separation

The circuitry in figure 3.3

is used for extracting synchronization signal from the video input signal.

These sync signals are later used by other parts of the digitizer.

The Elantec’s EL4583C is

used as sync separator. It is configured for extracting timing information

from a PAL video signal such as composite, vertical and horizontal synchronization,

burst/Back porch and Odd/Even field information.

The video signal, having

been amplified by the video amplifying circuitry, is fed into pin 4 of

the EL4583C. The IC has a built in 3 pole active filter to attenuate the

chroma signal to prevent colour burst from disturbing the sync slice.

Composite and Vertical Sync

outputs of the IC is used later throughout the stereo video digitizer circuitry.

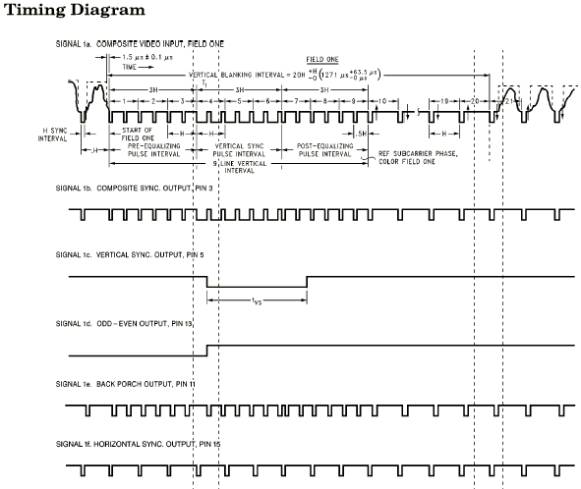

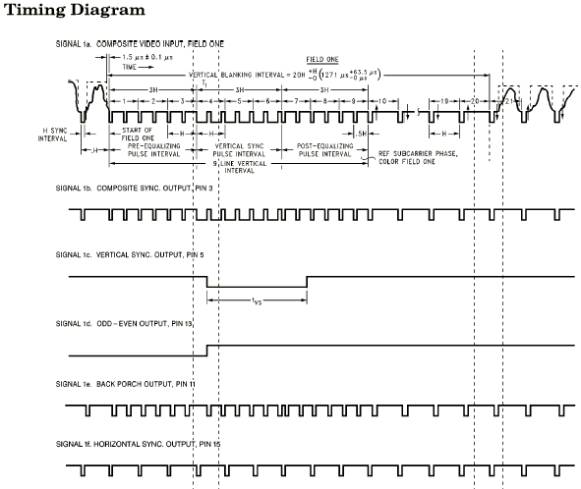

Figure 3.4 EL4583C’s timing information

Figure 3.4 shows the timing

diagram of the synchronization signal output of the EL4583C. Basically,

the IC isolates 5 different synchronization signals. They are composite

sync, vertical sync, odd-even output, back porch output, and true horizontal

sync.

The composite sync output reproduces

all the video input sync pulses, with a propagation delay.

Vertical sync leading edge is coincident with the first vertical serration

pulse leading edge, with a propagation delay.

Odd-even output is low for

even field, and high for odd field.

Back porch goes low for

a fixed pulse width on the trailing edge of video input sync pulses. Note

that for serration pulses during vertical, the back porch starts on the

rising edge of the serration pulse (with propagation delay).

Horizontal sync output produces

the true ``H'' pulses of nominal width of 5ms. It has the same delay as

the composite sync.

Video Timing ( Clock Generation )

Figure 3.5 Timing Circuit

Figure 3.5 shows the circuitry

where all the timing information needed by the digitizer hardware is extracted.

This includes the sampling clock used by the ADC and write clock used to

drive the SRAM (section 3.3.6).

The IC 74HC4017 counts past

the first 10 lines-some of which are in reality only half-length, and inhibits

collection of those-otherwise the captured picture would sometimes wrap-around.

Reset logic to 74HC74 is a crude attempt to give pseudo line locking of

what is essentially an asynchronous clock. The 74HC74 D flip flop in conjunction

with the 74HC4040 binary counter ensures a controlled number of samples

are made per video line (By setting the jumper at pin header H1). For example,

QA is 10 MHz, QB is 5 MHz and so on. For this project, a 20MHz oscillator

is used. 10 MHz is used as sampling clock to the ADC, while a ~5 MHz clock

for writing data to the digital storage block. This mean, we will get a

320 X 320 pixels video, with 8 bit per pixel.

T =1/f

=1/5M

Line Duration =320 * T

=64us

which is the same as the PAL line duration

Analogue To Digital Conversion

Figure 3.6 Analog To Digital Conversion

Figure 3.6 is the circuitry

for analog to digital conversion. Here, analog video input signal is sampled

at 10MHz, and an 8 bit digital data is obtained.

The TLC5540 8 bit

high speed ADC is used to convert the analogue video signal into digital

data. The ADC is always enabled, and running on a free running clock of

10MHz. It is configured for converting analogue signal in the range of

0.61V – 2.63V. Ferrite Bead is used to give a clean undistorted supply

voltage as required by the ADC.

The data output lines of

the ADC is fed into the 74HC541 octal line driver for buffering purpose.

The enable pin of the 74HC541 is controlled in such a way that signal conflict

on the shared data line(Y1-Y8) will never occur.

Digital Data Storage

Figure 3.7 Digital Data Storage

Digital data storage is meant

for providing a temporary storage for the sampled digital video data prior

to transferring it to the PC. It is shown in figure 3.7. Basically, the

digital data storage block is made up of the TC551551CP-70L static random

access memory (SRAM), and some 74LS193 counter ICs. The TC551551CP-70L

acts as an asynchronous data buffer as the speed of data being written

into RAM is a lot faster than the speed of data being read from it.

The TC551551CP-70L is a

1M bit (or 128K byte) SRAM. It is chosen as the resolution of the video

been captured by the stereo video digitizer is at 320 X 320 pixels (8 bit/pixel).

This means a capacity of 100K byte is needed. The TC551551CP-70L

has a 70ns access time, which is sufficient for a 10 MHz sampling-clocked

system. (Note: 70ns is about 14.3 MHz). However, use of a faster SRAM is

recommended in improving the system performance. The only drawback is that

it is hard to find one in Malaysia.

The series of 74LS193 binary

counter connected in cascade is meant for generating address for the SRAM

address line. The output data pins of these counters are connected to the

address pins of the TC551551CP-70L. There is a Master Reset (denoted by

MR) control pin for resetting the address line to 0, and a Count Up (denoted

by CU) for counting up the address when there is a clock provided.

The WE control line on the

TC551551CP-70L is meant for controlling data read or write onto the SRAM.

When WE is low, the SRAM data pin is meant for input; when it is high,

the data pins are meant for output.

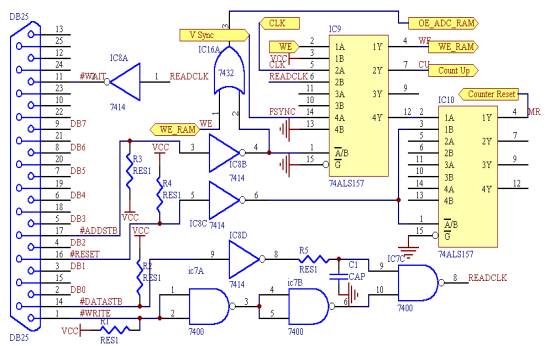

Control Logic And Enhanced Parallel Port Interfacing

D0 through D7 (or pin 2 through 3 of IC 11) should be fitted with 4.7 kW

pull down resistor.

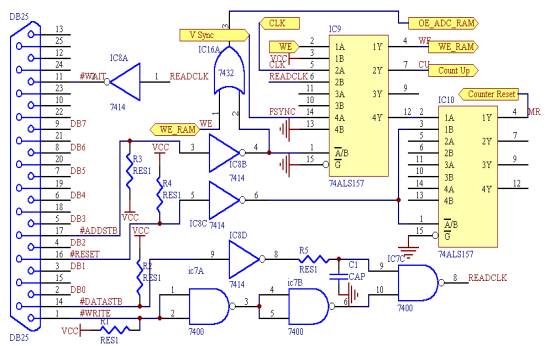

Figure 3.8 Control Logic and EPP interfacing

The circuitry in figure 3.8 is meant for generating handshaking signal

as defined by the IEEE1284 Enhanced Parallel Port protocol. Please refer

to figure 2.1 for timing diagram reference.

Figure 3 shows a typical

read cycle. During read cycle, write and data strobe will be held low by

the PC parallel port internal circuitry. On seeing this, IC8 and IC7 will

generate a high at the Wait control line, so that the PC will read data

from IC11 (74HC541 octal buffer). A pulse named READCLK is generated during

this process, which is used for clocking the CU pin of the digital storage

block.

Since the MR and CU of the

digital storage block should be controlled by the parallel port interface

logic during read cycle; but should be controlled by the analogue circuitry

of the video digitizer otherwise, a multiplexer is needed for selecting

the correct control signal at correct time for MR and CU. For this purpose,

two 74LS157 quad 2:1 MUX are chosen. The Address Strobe and Reset pin of

the EPP port are used as control line to drive these two MUX, since they

are not needed in the EPP handshaking.

During read cycle, the Address

Strobe is pull low to select READCLK for the digital storage CU. Reset

line should be pulse low for a short interval to reset the counter in the

digital storage block. In short, the counter will be reset, and data is

read out from the SRAM.

When the read cycle ends,

both Reset and Address Strobe are pull high. This will let the control

signals from the analogue circuitry (the sampling CLK and V Sync) to take

over the control over the CU and MR or the digital storage block. As long

as another data read cycle does not start, the SRAM is constantly been

updated with data sampled from the video signal.

Apart from that, the pulse

that is generated by the Reset line will also trigger the 74LS76 flip flop.

Configured as a toggle flip flop, the 74LS76 will let the stereo video

digitizer switch its video input channel whenever a complete frame of video

is transferred to the PC. With this approach, the PC can get a digital

stereo video source.

Power Supply

Figure 3.10 Power Supply

The stereo video digitizer needs +5V and –5V supply. The digitizer board

has circuitry onboard to provide a regulated +5V and –5V votage source,

as shown in figure 3.10. This part is also important in the sense

that it regulate the input voltage, and protect the digitizer board from

problem as over-current, spikes, and voltage surges.

The +5V supply is realized using a 7805 voltage regulator. ICL7660

is used for inverting the input power supply. A 7905 is used for generating

a regulated –5V supply. The main supply should be in the range of

7—9V.

Building the Hardware

Building the stereo video

digitizer involves 3 main steps. They are drawing the schematic diagram,

design and fabricate the printed circuit board and mounting the electronic

components.

For drawing the schematic

diagram, the Protel Advanced Schematic software is used (see figure 3.11).

A schematic diagram let us graphically connect different electronic together

in order to make up a circuit.

Figure 3.11 Protel Advanced Schematic schematic drawing software

After the complete schematic

of the stereo video digitizer is drawn, we will extract its netlist. This

netlist will be used in a subsequent software in the Protel family, the

Protel Advanced PCB, for designing the printed circuit board (PCB) layout.

Figure 3.12 shows a screen capture of the Protel Advanced PCB in action.

For this project, the circuit

board is designed in double-sided. This provides a more compact design.

When the design is completed,

we can fabricate it by sending it to any chartered PCB fabrication factory

for fabricating the PCB.

Lastly, when the PCB is

fabricated, we will mount the needed electronic components onto it.

Figure 3.12 Protel Advanced PCB

Due to time constraint, I only fabricate PCB for the analog part. The

digital part is done on strip board. You can download

the Protel PCB files which i've drawn here. However, their are scattered

not in sequence. Please refer to the circuit described in this page.

Known Problems and Limitation

The first limitation of

the stereo video digitizer is that it does not do any chroma signal filtering.

If a colour CCD camera is to be used, the colour burst chroma signal should

be attenuated prior to been sampled by the ADC. Otherwise, the video will

display unwanted herringbone pattern.

The CCD camera is connected

to the digitizer using a coaxial cable. Thus, the video input connector

should be terminated using 75W resistor to match the coaxial cable impedance.

The parallel port interface

is susceptible to noise. The control line Address Strobe and Reset from

the PC will cause unwanted result on the video grabbed if there are spikes

within the lines (which usually have). For example, a spike on the Reset

line might reset the address counter when it should not; whereas spike

in Address Strobe might incorrectly trigger the counter. A low pass filter

(simple RC network) should be connected to these lines to attenuate the

spikes. Actually, i didn't solve this problem in my project. It cause my

captured video to experience drift, a serious problem. Should somebody

fixed it, please email me.

Although the EPP interface

has a rated speed of up to 2 Mbyte / s, the actual data transfer cannot

achieve this speed. This is due to the fact that there are other hardware

delays within the digitizer circuitry, and software overheads at the PC

part.

In theory, to get a picture

with square pixel, a clock rate of 14.75 MHz for PAL should be used.

Since the stereo video digitizer

contains digital and analogue circuitry on the same board, current spikes

from the digital part may reach analogue part where they gets amplified

and cause errors, oscillations or instability within the whole analogue

circuitry. To solve this, the digital ground plane should be separated

from the analogue ground plane. The interconnection of the two separate

ground plane can e done on the most stable reference ground point of the

system (ie: the power supply ground point ).

Future Development

In order to improve the data transfer

rate of the digitizer, it can be ported to a faster bus (rather than EPP)protocol,

such as the ISA bus which has a clock of 4MHz. You can take a look on my

simple ISA prototyping board described elsewhere on my homepage.

The circuit design can be

greatly simplified by using a FIFO as digital data storage rather than

SRAM. This is due to the fact that a FIFO does not need any address line.

For example, there are FIFO from OKI, IDT and ISSI.

The digitizer can be used

for colour signal decoding through software. For a headstart, check out

W.A

Steer home-built video digitizer page.

Eventually, feel free to email me

on any issue relating to this project.