Introduction

After completing my first clockwork project ("Windus", the Meccano-powered tram engine), I started thinking about my next one. I didn't want to spend as much time building it as I did "Windus". In particular, I preferred to have a clockwork drive that was complete with wheels, so that led me to using a

vintage commercial mechanism. I had a Hornby Model 40 0-4-0 O gauge locomotive that was built in the fifties (albeit with a rather amazing top speed), seemed to have the perfect coupled mechanism for a small 16mm scale narrow gauge locomotive. Not wishing to sacrifice my intact Hornby locomotive, I was able to get a mechanism (complete with wheels and coupling rods) of the same vintage off eBay at a reasonable price. After a thorough cleaning and a bit of lubrication, the motor was ready to be incorporated in my creation. With the bare chassis, I started experimenting to see how much weight I needed to add in order to slow it done a bit. It was kind of fun to watch the thing whiz around the railway for a couple loops, anyway. But what to build?

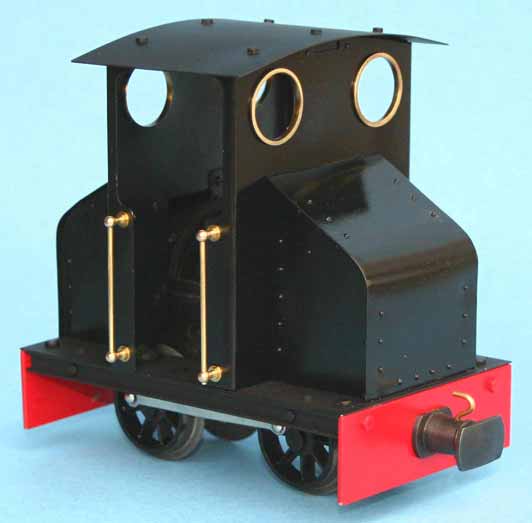

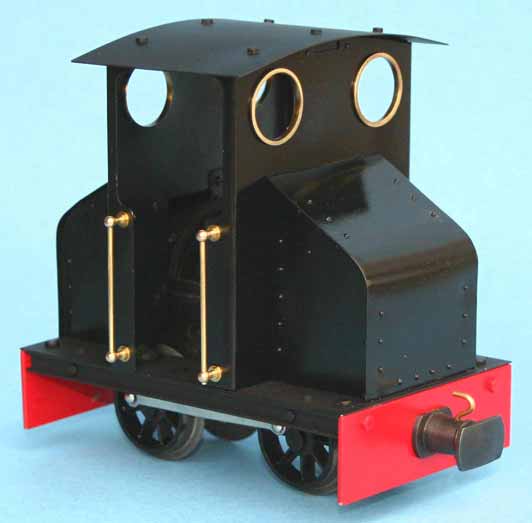

I dig through the parts bin yielded a couple of cab ends complete with spectacle rings from derelict Mamod live steam locomotives. I figured that would save me some construction effort. Playing around with them I came up with the idea of a very small steeplecab locomotive, maybe the sort you would have seen on a narrow gauge railway in a quarry or a steel mill.The frame was made from the usual material-of-choice for these sorts creations- K&S 0.032" thick sheet brass. Brass "C" channel was added to give the sides some depth and strength. These pieces also allowed me to add (and hide a considerable amount of lead weight onboard) in order to slow it down. Thick brass strip and Brandbright center buffer couplers were added to complete the chassis and it was fastened to the Hornby mechanism using the two existing standard mounting holes.

The Mamod cab ends were then sandblasted to remove the original paint and lining. As they have to fit over the mechanism (with the spring in the unwound position), I cut holes in the ends with the trusty Dremel and a cutoff wheel. A bit of playing around with cardboard mockups yielded an acceptable design that fit over the mechanism. The end cowls were then made from sheet brass and soldered up, with a few decorative rivets added for good measure. The roof was made from sheet brass as well. The cab ends, cowls and roof were all bolted together, then the whole body was finally bolted to the frame.

The winding shaft on the clockwork mechanism lined up perfectly with the side opening between the cab ends. On the unaltered Hornby Model 40, the two control rods (on/off brake and reverser) protruded from the back the tank locomotive cab quite a distance. (Unsightly from a model locomotive perspective, but necessary to allow the figures of younger locomotive drivers to grip them, I presume.) On my creation, I wanted both control rods to be hidden neatly in the cab. A piece of brass rod was turned in the lathe to round off one end and the other end was drilled and tapped 6 BA for a mounting bolt. It was simply bolted to the reverser lever arm on the motor. For the on/off brake, a control rod was bend up and one end was connected to the lever on the clockwork motor and the other end was brought back into the cab through a hole in one of the cab ends. A Mamod buffer (perhaps from the same scrap locomotive as one of the cab ends?) was turned in the lathe to make a nice control knob.

With the locomotive complete, it was painted a very dark gloss Brunswick green (so dark that it appears black in most photographs). The end beams were painted bright red for contrast. Brass spectacle rings were added, along with handrails on the cab sides. It is still awaits proper cast nameplates (mainly because I haven't thought of a suitably clever name for it yet). In the interim, it carries plates with the number "7".

In April 2005, the completed locomotive won a "Highly Commended" certificate at the Association of 16mm Narrow Gauge Modellers annual general meeting at Stoneleigh in the UK. It also has the distinction of traveling through the Channel Tunnel in my suitcase, aboard the Eurostar). It currently sees service on my garden railway, hauling everything from tipper wagons to inspection trains (as shown below).