|

| Flywheel Removal Tool Cheap and Homemade |

|

| Tired of busting knuckles trying to remove your flywheel? Have you ever 'gently' pried it off with a crowbar? Although it works (kinda), it really isn't fun, and who knows what you're chewing up with that bar. As for me, I'm just a regular guy with a garage full of tools, but the tools I don't have are the special 'one use only' items that cost a lot, such as a crank gear removal tool, a nice Ron Lummus Flywheel removal tool, or a number of other things. Since I had to remove my 8 dowel flywheel, and have an 'active' imagination, I though I would give this a try. |

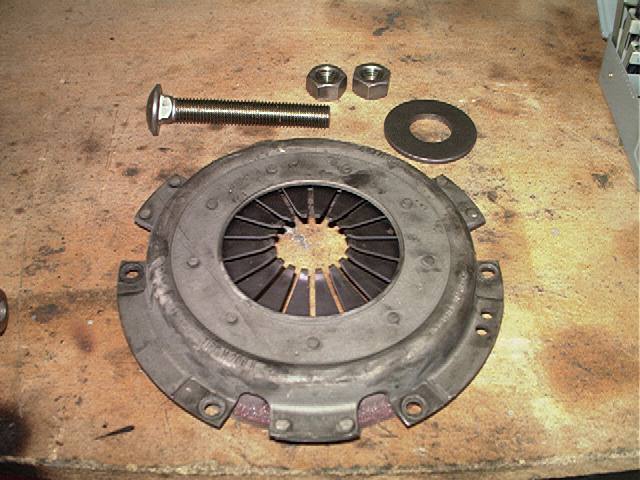

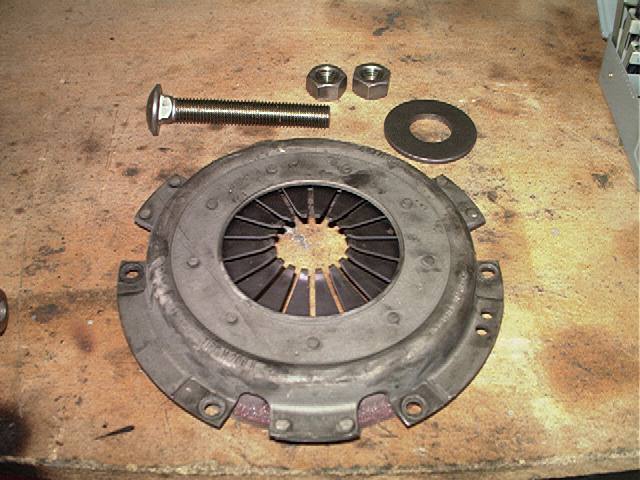

| Here's what I'm starting with: A very old, and very rusty stock pressure plate, a couple of 3/4" nuts, and a matching carriage bolt to go with it that has about 4.5 inches of useable thread on it, and a large washer that barely fits the nuts in the middle of. All the steel is regular, not zinc plated or galvanized, since they have to be welded. |

|

| First thing I did was to grind away all the rivits holding the two main pieces of the pressure plate together, then grind off the rivits that hold in the spring steel with all the 'fingers' on it. I found grinding did this faster than drilling. |

|

|

|

| Next, I cut two 6.5" pieces of angle stock. Then, after spending a good amount of time to make sure I had the washer centered in the upside down pressure plate. I put the bolts that hold the pressure pate to the flywheel around the inside edge of the center hole on the pressure plate, and was able to center the washer easier. I then laid the two pieces of angle over the washer, inside the pressure plate, and tacked it together. |

|

|

| After fully welding the angle to the pressure plate and the large washer around all the seams, I again laid the pressure plate on its back, and welded the 3/4" nut flush with the washer. I did a washbead on all my welds with a pretty hot setting on my welder to make sure I got the strength that I would need. I made several attempts to get a better photo than this, but my camera's 'auto focus' had a hard time focusing on the reflective metal. I think you can see the jist of it though. |

| After the whole thing was tacked together, I welded every seam where the angle met the pressure plate, and everywhere the angle met the large washer. The way this will work, is the washer will have a pulling force on it to try to pull it off the angle, the angle will be forced into the pressure plate. To do it over again, I would have actually designed it differently, but we'll see if this works first. If not, I have another rusty junk pressure plate laying around. |

| And with the gland nut off the flywheel (wish I had the KYMCO tool for that), I put the flywheel lock on just finger tight, I did not want the lock to 'wedge' the flywheel on. So should we give it a test, and see how it does? It's not the prettiest thing in the world, but looks don't make tools work, so let's see what we happens! |