|

System |

After upgrading to a 35 lb CQR with 30 feet of chain, it only took a couple of times of weighing anchor to see the need for a washdown system. A CQR has an amazing way of bringing half the seabed with it and I needed a way to keep the foredeck and anchor locker clean.

The following is a list of items required for the installation:

1. 1 ea. Sure Flo Pro Blaster washdown pump ($89.95 at Boater's World)

2. 1 ea. Par Pump Guard strainer ($12.99 at Boater's World)

3. 1 ea. 15 amp circuit breaker ($15.95 at Boater's World)

4. 1 ea. Single circuit breaker panel ($15.95 at Boater's World)

5. 14 ft. 3/4" hose ($10.50 at Boater's World)

6. 7 ft. #12 AWG duplex cable ($6.23 at Boater's World)

7. 1 ea. Bronze 3/4" T ($4.99 at Boater's World)

8. 3 ea. 3/4" NPT to 3/4" hose barb ($11.97 at Boater's World)

9. Misc. Cable ties (on hand)

10. Misc. Cable terminals (on hand)

11. 4 ea. #10-32 machine screws, washers and nuts (on hand)

12. Misc. hose clamps (on hand)

13. Silicone caulk (on hand)

Total cost of project: $168.53

The following is a list of tools used to complete the project:

1. 3/8 in. battery powered reversible drill

2. 1 set drill bits

3. 1-1/8 in. hole saw

4. Screwdrivers

5. 1/4 in. drive socket set.

6. Wire strippers

7. Crimp tool

8. Ty-wrap tool

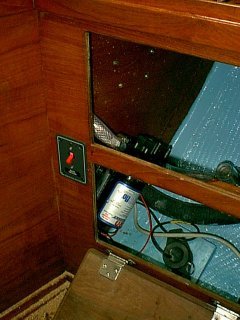

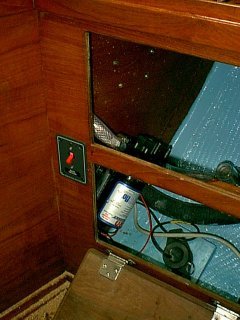

After studying the situation, I decided to locate the pump beneath the starboard side of the V-berth behind the lower locker door and on the forward bulkhead of that compartment.

Since the anchor washdown system would not be used at the same time as the shower, I decided to tie into the DC power for the shower sump pump to avoid one more long DC cable run. This left me a 7 foot cable run and I installed a single circuit breaker panel on the teak face below the V-berth.

The pump's intake was plumbed into the seawater intake for the head using a bronze 3/4 inch T and three 3/4 inch NPT to 3/4 inch hose barb fittings.

The pump's output was plumbed to a 3.4 inch bronze sillcock located in the anchor locker.

This 3/4 inch hose was routed through the forward bulkhead that the pump was mounted on after cutting an appropriate hole with a hole saw. The line was then routed along the fore and aft vertical bulkhead above the holding tank and secured with cable ties.

Copyright 2001-2009 No duplication of any portion of this website without express permission.

Permission may be obtained by e-mailing the webmaster at

earlylight160@yahoo.com.