0. Introduction

The equations in this paper were derived mainly

because the author has been kown to ask the question,

"How was this equation derived?" In his

time as a curious boy, not one toy was spared from

being disected and reverse-engineered. On the other

hand...

In the case of vented-box loudspeakers, ports are

used to extend its low-frequency extension by using

the energy at the rear side of the driver unit's cone.

In the case of bandpass enclosures, ports are used to

limit the passband of the loudspeaker system. Vented

systems are known for being sensitive to design and

construction errors or misalignments. The driver's

Thiele-Small parameters should be as accurate as

possible so that equations and CAD software can yield

results that are most relevant to the driver and

design parameters. We want to further reduce the

chance of misalignment by carefully building the

enclosure, but the question of port diameter and port

length now arises.

As well as being a function of enclosure volume

and vent radius, port length is also dependent on the

speed of sound. Several books and Internet sites

quote equations for port diameter and vent length,

but nearly all of these equations assume the speed of

sound to be 344m/s. It will be shown that the actual

speed of sound is a significant factor in calculating

the required port length. Although the effects on the

enclosure's resonant frequency may be insignificant,

the exact port length would be helpful in calculating

enclosure dimensions. More so when enclosure size is

critical.

It is often the case of the vent(s) being too long

to fit in the accompanying enclosure. The builder has

to reduce the port radius so that port length is

consequently reduced, but in doing so the problem of

port noise arises. Introducing flares to the port can

significantly reduce port noise while still having

practical port dimensions. However, the author has

yet to see an equation for calculating the dimensions

of flared vents. In this paper, an equation is

presented that can be used to approximate the

dimensions of flared ports.

1. Cylindrical Vents

In mechanical terms, a vented-box is simply a

spring-mass resonant system. The air in the box acts

as a spring and has a stiffness that is directly

proportional to the port's area. On the other hand,

the lump of air in the port acts as a lump of mass.

The box resonant frequency can be calculated from the

following equation.

where:

Fb - box resonant frequency (Hz)

Cmb - box compliance (m/N)

Mmp - port mass (kg)

pi = 3.1415926535897932384626433832795...

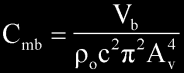

Cmb can be calculated from,

where:

Vb - net box volume (cubic meters)

po - density of air (kg / cubic meters)

c - speed of sound (m/s)

Av - port radius (m)

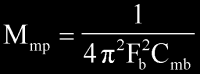

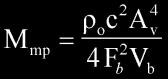

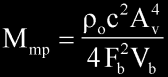

From the equation of Fb, we have the equation for Mmp

(as a function of Cmb and Fb),

or

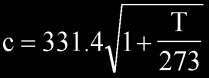

The speed of sound can be calculated from,

where T is the ambient temperatur in Celsius degrees.

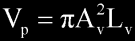

Now, the volume of air, Vp, in the cylindrical port can

be calculated from the following equation.

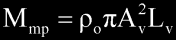

where Lv is the port length in meters. Since mass is

equal to volume multiplied by density, the lump of mass

in the port can be calculated from,

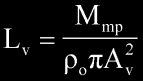

Manipulating this equation for Lv,

and since

Lv

simplifies to,

However, both ends of the cylindrical tube are

actually loaded with a small mass of air. According to

Beranek, the flanged end of a tube actually "extends"

by 0.85*Av whereas the free end of the tube extends by 0.613*Av.

Usually, the port is mounted flush against the

loudspeaker baffle while the other end of the port is

left unflanged, therefore the corrected equation for Lv

is,

2. Multiple Cylindrical Vents

With high-power driver units, port noise can be an

audible problem. A solution is to use a port with a

larger vent radius. Alternatively, the builder may elect

to use two or more vents when a single large vent is not

readily-available or impractical to build.

From the Loudspeaker Design Cookbook (by Vance

Dickason)

where:

Dt = effective diameter of the combined vents

D1, D2 = individual port diamter

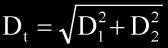

For equi-diameter vents, D1 = D2, and so

Now D = 2A, so

or in the case of N number of "equiradius"

vents,

where Av is now the effective vent radius. Cmb for

multiple vents is now,

Since all the ports have equal mass, each port will

have mass equal to

Therefore each port length will be

For example, given:

c = 342.2m/s (at 18 degrees Celsius)

N = 2 ports

Av = 0.045m

Fb = 16Hz

Vb = 0.142 cubic meters

Each port length will be Lv = 0.972m (or 38.3inches)

If the ambient temperature happens to be 35 degrees

Celsius (during summer), c increases to 352m/s

Consequently, Lv = 1.03m (or 40.7inches)

When only one vent is used, the change in port length

(due to change in temperature) can be neglected. But when

two or more vents are used, the change in ambient

temperature has a significant change in port length.

3. Flared Vents

-- 22 June, 2002: Please note

that this section of this page needs to be corrected.

Apparently, the equation presented below over estimates

the end-correction, so please disregard this section

until the necessary corrections have been made. I

apologize for any inconvenience this may have caused.

When the calculated port length is too long, given a

particular enclosure size and tuning frequency, the

builder may slightly decrease the vent radius, which will

correspondingly reduce port length. Unfortunately, by

doing so, port noise will almost certainly become a

problem; to rectify the problem flared vents may be used.

First, we derive the equation for the volume of air in

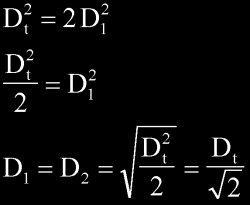

the flare. Pictured below is half of the cross section of

a port's flared end (along with the derivation for the

flare volume).

Fig. 1: Derivation of flare volume.

Rotating the shaded area about the y-axis

gives the volume of air in the flare. The flare radius is

a function of y and is given by the equation

A(y) = Am - sqrt(Af*Af - y*y)

where:

Am - mouth radius of the flare and is equal to Af +

At

At - throat radius of the flare

Af - flare radius

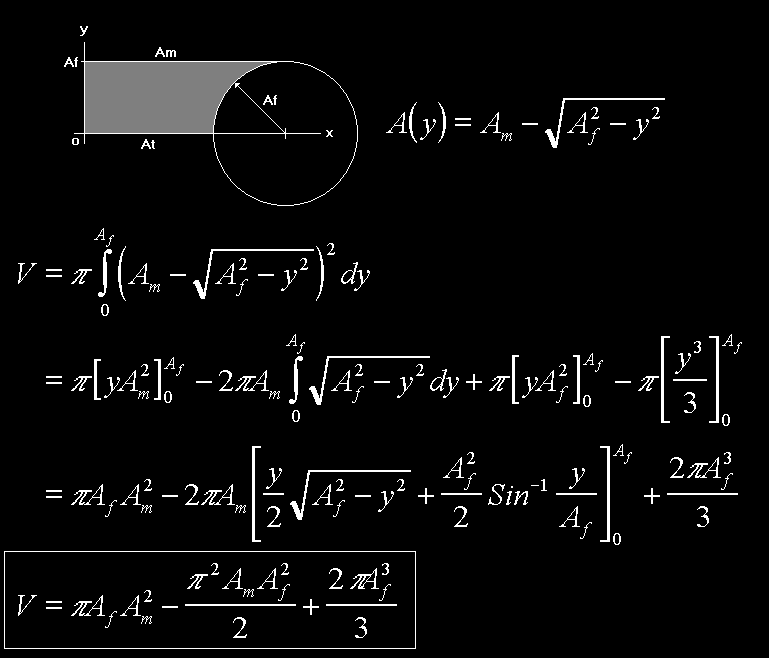

When both ends of the cylindrical vent

have flared ends like the one pictured below,

Fig. 2: Cylindrical vent with both ends

flared.

The required tube length, Lt, can be

calculated from

Lt

= N*c*c*At*At / (4*pi*Fb*Fb*Vb) - 0.85*Am - 0.613*Am

- 2*V / (pi*At*At)

and if only one end is flared,

Lt

= N*c*c*At*At / (4*pi*Fb*Fb*Vb) - 0.85*Am - 0.613*At

- V / (pi*At*At)

For example, given both ends are flared and:

c = 352m/s (at 35 degrees Celsius)

N = 1 port

At = 0.045m

Af = 0.0254m (1inch)

Fb = 16Hz

Vb = 0.142 cubic meters

Each port length will be Lv = 0.382m (or 15inches) as

opposed to Lv = 0.483 (or 19inches) when no flares are

used.

Assuming (just assuming) for a moment that air was

incompressible, using the continuity equation for fluids,

At*At*vt = Am*Am*vm

where vt and vm are the fluid velocities at the throat

and mouth respectively, we can calculate the appoximate

exit velocity as

vm = At*At*vt / Am*Am = 7m/s

which translates to a 60% reduction in port velocity (assuming

vt to be 17m/s or 5% the speed of sound). Halfway out the

flare, the air velocity is 15m/s -- 12% down from 17m/s.

In practice, we can expect slightly higher exit

velocities as air is not an ideal fluid.

4. Conclusion

A derivation for the general equation for port

velocity is presented. It was shown that port length is

not only dependent on port radius and net box volume, but

also on the actual speed of sound. The effects on

calculated resonant frequency may be neglected, but the

effects of the change in the speed of sound on the port

length cannot be ignored; especially when using two ore

more ports.

An approximate equation for flared ports was presented.

The presented equation may be used by builders to build

their own flared vents when long cylindrical vents are

impractical or when commercial flared vents are either

too expensive or unavailable.

(corrections?)

|