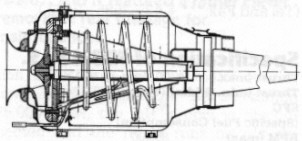

This is a drawing of my first engine. It took around 3 months to build and the compressor wheel was made of ply wood.

This is a drawing of my first engine. It took around 3 months to build and the compressor wheel was made of ply wood.Maximun thrust was 5.5lbs at 70,000rpm and it idled at 20,000rpm.

The engine ran very well on propane but rather hot on liquid fuel due to a difficult vapouriser.

Never the less, a lot was learned from this engine and it helped to develop the second. The engine was 4.5" dia. x 11" long.

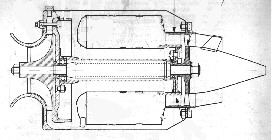

The picture to the left shows a drawing of the second engine I built.

The picture to the left shows a drawing of the second engine I built.It uses a turbo compressor wheel, from a Porsche sports car, for its compressor but the rest is completely home fabricated.

The engine uses a much more reliable vapouriser and runs on automotive deisel straight from the fuel station.

Maximum thrust is about 8.5lbs at 100,000rpm and it idles at around 30,000rpm.

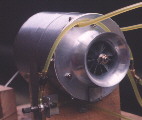

Picture shows my latest engine on its test stand.

Picture shows my latest engine on its test stand.The pressure guage, to the right of the picture, is used to indicate the internal casing pressure. This is used to calculate the motor's rpm, which would be difficult to measure, directly, at mid throttle and above.

The fuel is injected and controlled by a small electric fuel pump and a 2 stroke oil/parrafin mix lubrication is forced to the bearings by the engines own casing pressure.

The engines comprise mainly of 0.5mm thick stainless steel parts which are spot welded together with a simple home made welder.

The engines comprise mainly of 0.5mm thick stainless steel parts which are spot welded together with a simple home made welder.The turbine wheels, which are also made of S/S, are machined from 6mm plate. The blades are shaped by hand with a Dremmel fitted with a 22mm dia. grinding disc and finished with needle files.

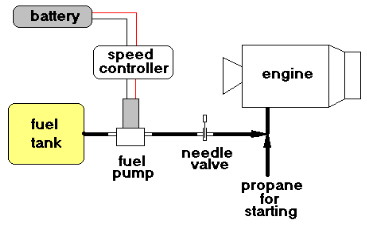

Starting the engine is fairly straight forward and only takes around 30 seconds.

Starting the engine is fairly straight forward and only takes around 30 seconds.Initially the engine is warmed up on propane fed in to the fuel system, via a quick release connector, down stream of the fuel pump.

Propane is introduced at low pressure (ie <20psi) and the engine spun to about 3000rpm with a modified hair drier. The hair dryer forces a lot of air through the engine, and this is important for a successful start up, not high rpm's as some people think.

The hair drier is then turned off and as the engine spools down the propane is ignited with a simple flint, blow torch lighter applied to the rear of the jet nozzle.

The hair drier can now be re-started and after a few seconds warming time liquid fuel can be introduced. As the fuel flow is increased and the engine rpm's rise, the hair drier is removed and the propane can be progressively cut back until only liquid fuel enters the engine.

The hair drier can now be re-started and after a few seconds warming time liquid fuel can be introduced. As the fuel flow is increased and the engine rpm's rise, the hair drier is removed and the propane can be progressively cut back until only liquid fuel enters the engine.Throttle control is now purely by means of the fuel pump delivery and a home made electronic speed controller governs this.

Don't hesitate to mail me with comments or questions on:

Don't hesitate to mail me with comments or questions on:

andygermaney@ntlworld.com

Small Gas Turbine and Modeling Links.

- Traplet Publications. Magazines & books inc. turbine stuff.

- Mike's Models. Model shop selling radio control model jets.

- AMT Turbines. Company selling ready made gas turbines.

This is a page from

Andy's Leisure Site.