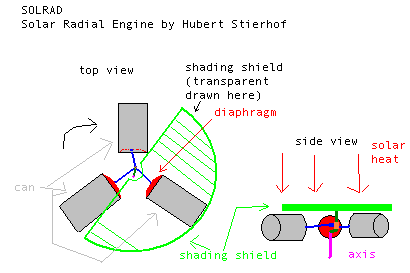

SOLRAD Engine

A SOLar RADial engine is a very

slow rotating engine, powered by the solar heat. The rays heat up the cans,

which are not coverd by

the shading shiled (parasol, sunshade). Air expands and pushes out the diaphragm.

The diaphragm is connected by a rod to the crank

shaft (bearing). When the can gets shaded by the rotating shading shield,

its air will contract and pulls back its rod.

The engine is absolutely SELF STARTING.

It's very slow. Rotations per BELOW 1 RPM, but with a relatively high torque.

That's why no ball bearings are needed, and simple

brass tube bearings can do the job.Using beer or Coca Cola cans, the torque

(depending on the sun's power) may rise above to

1 Kpcm (Kilopond on a one centimeter radius; equals 0.1

NEWTON-Meter) when the stroke length is about 20mm, so a power

output of 10 Milliwatt will be reached.

This power output can be easily improved by

- using BIGGER cans (output will rise in relation to volume)

- using MORE cans (6, 8, ?)

- mounting a mirror (kitchen foil) to each can

to concentrad the sunlight (output will double)

The engine is best applicated as a water pump. The simplest pump can be an

additional can with a diaphragm and automatic valves or an

Archimedian screw or an Egyptian waterwheel (using buckets on a chain).Althoughh

10 mW power output is not much, an impressiv engine

can be built, which lifts > 3 Liter of water, 1 meter high in one hour.

That's enough to water flowers in a small garden.

...or a little pond's fountain.....or a sun tracker...

....or to drive a gadget of any type...

...just let your phantasy run wild on it !

DRAWING

Here some more pictures: a detail of the axis a view from the back ....the cylinders only the engine without shader(side) (front)

the shading shield (and the shader's back)

The engine shown here is made of 3 Cappuccino-can of about 650cc volume.

They are 80mm in diameter and 130mm in height.

The crank shaft is 7mm off the axis, so the stroke length of the

diaphragms is 14mm. At first test runs the RPM was 0.25, or in

other words 15 rotations per hour.

The SOLRAD can be build in two versions:

- with a rotating shading shield or

- with rotating cylinders and fixed axis

Recent test runs showed, that the

SOLRAD with rotating

cylinders and fixed axis (see

below; some more photos the next days)

runs best and because of its fixed shading shield, it is less fragile and

so should be the preferred design.

another view of the SOLRAD with rotating cylinders

front view side view back view

Running free RPM increases to 0.5, which are 30 rotations per hour.