ANTIMICROBIAL

FINISHES

PRACHUR BHARGAVA

INDERPREET SINGH

|

S.no |

TOPIC |

Page no |

|

|

|

|

|

1 |

Introduction |

3 |

|

|

|

|

|

2 |

Microorganisms

and their effect on textiles. |

4 |

|

|

|

|

|

3 |

Anti-microbial-Agents |

7 |

|

|

|

|

|

4 |

Classes

of anti Microbial Agents |

9 |

|

|

|

|

|

5 |

Methods

of application of Anti-microbial finish. |

13 |

|

|

|

|

|

6 |

Effect

of Anti-microbial finishes on chemical structure. |

14 |

|

|

|

|

|

7 |

Effect

of Anti-microbial finishes on Mechanical Structure |

17 |

|

|

|

|

|

8 |

Assessment

of Anti-microbial Finishes |

19 |

|

|

|

|

|

9 |

Anti-odor

finishes |

22 |

|

|

|

|

|

10 |

Surgical

applications of anti-microbial finishes |

24 |

|

|

|

|

|

11 |

References |

25 |

Clothing and textile materials are carriers of

microorganisms such as pathogenic bacteria, odor-generating bacteria , and mould

fungi because of the adhesion of these microorganisms on fabric surfaces. Most

textile materials currently used in hospitals and hotels are conductive to

cross-infection or transmission of diseases caused by microorganisms. This has

created increased pressure for protection of personnel with functional clothing

and materials i.e. application of Anti-microbial Finishes.

In

this review first we have discussed about various microorganisms and their

effect on textile materials. Next we have discussed various Anti-microbial

finishes, their methods of application and their effects on the chemical and

mechanical properties of fabrics. One of the most important applications of

Anti-microbial Finishes is in Surgery and related health fields. In the last

section we have tried to highlight this important application of Antimicrobial

Finishes.

MICROORGANISMS

AND THEIR EFFECT ON TEXTILES

Microorganisms

are a part of our daily lives. They encounter and accompany the human being in

most different shapes –mostly unnoticed. Microorganisms i.e. bacteria, moulds

yeast are playing an important role in numerous biological reactions. The skin

is also crowded with innumerable organisms, which mostly are part of natural

skin pH value.

Smallest organisms

–biggest effects

Microorganisms are extremely adaptable. If the environment is

favorable certain bacteria grow in no time from single germ to millions Germs

very rapidly develop via cell division: every 20 minutes they double their

population

For their growth they mainly require humidity and as a culture

medium organic material is required which they attack and digest with enzymes.

This is how soil bacteria and moulds are doing their invaluable job as humus

producers. The same way however they destroy material of wealth for mankind.

Especially good environments for the microorganisms living on the skin are areas

with high humidity.

Microorganisms on textiles

Due to the close contact between skin and textiles after only a

short wearing times microorganisms crowd them. Additionally their environmental

conditions on textiles are similarly favorable as on the skin and thus support

the microbial growth.

Not all

microorganisms are alike.

A rough subdivision can be made as:

-Bacteria

-Yeast Fungi

-Virus

Bacteria: Bacteria

are categorized as

Gram

positive

Gram

negative

This classification goes back to the Danish pathologist Gram

(1884) who found the test method for diversification of cellulose membranes of

bacteria:

On the skin mostly Gram-positive

bacteria like Staphylococci and different Coryne bacteria are found.

Gram-negative

bacteria

like Escheria coli are found in feces.

Microorganisms are invisible but there presence can be easily

felt, smelt or even seen when they are uninhibited reproducing and then deploy

their activity. They produce different degradation products which man senses as

unpleasant smell growing to stench.

Bacteria e.g. convert sweat into stinking substances like carbon

acid aldehyde and amines.

The proliferation of the microorganisms causes destruction of the

material on which they are growing.

Fresh and

Hygienic?

It is wide spread belief that washed textiles are hygienic, fresh

and clean .A study shows that this belief is partially realistic. The following

test prove that this postulate:

50

test persons have been wearing for 25 days sanitized antibacterial finished wool

stockings and parallel stockings without treatment were tested. Everyday the

stockings have been washed at 40 C and have been worn again next day .In 5 days

intervals the quantity of bacteria before and after washing have been measured.

Independently of the number of washes the especially finished stockings showed

always the same fresh hygienic and clean results .The not so especially finished

stockings showed for a certain time after washing a reduced amount of bacteria.

However after that time the number of bacteria grew explosively.

Conditions

required for the growth of these organisms are:

Nutrients:

Soil,

dust and some textile finishes can all be sources of nutrients for

microorganism. Perspiration contains salts, amino acids, carboxylic acids and

other essential nutrients. Dead skin cells or oils secreted from the skin are

also a potential source of carbon. Cellulose itself is not a nutrient, but many

bacteria produce extra cellular cellulose enzymes, which convert cellulose into

the readily metabolized glucose.This has the dual effect of promoting further

growth, and degrading the Fiber.

Water

Porous fibers of hydrophilic nature provide

a suitable environment for

Growth of microorganism, Human beings have been estimated to have been

estimated to give off an average of 1OOg/ hour of water as perspiration, which

accumulates in clothing and bedding. A humid environment will provide enough

water to support fungal growth. Bacteria need more water and require the fabric

to be damp.

Oxygen

The atmosphere provides a ready source of

Oxygen.

Warmth

Most fungi and bacteria will grow at ambient temperatures of

10-200 C. Certain bacteria prefer the slightly warmer conditions of clothing or

bedding in close proximity to the skin. These bacteria such as Staphylococcus

aureus, S. epidennis and Corynebacterium sp. are those most commonly found on

the skin.

Affect of

Microorganism growth on fabric

In the majority of

cases, the presence and growth of microorganisms passes unnoticed in certain

circumstances however, undesirable and possibly serious effects can occur.

Health

The growth of certain microorganisms has been known to affect the

health of the user. The consequence of infection in some case may only be a sore

throat caused by Escherichia coli. S. aureus is known to infect skin, surgical

wounds and burns, and can have serious effects. Textile products such as

bedding, curtains, uniform and mops may be involved in the transport of bacteria

within hospitals. Athlete’s foot is

a common infection caused by the fungus Tricophyton mentagrophytes. The role of

socks in retaining moisture and nutrients may be significant in the growth of

this organism. Microorganisms may produce metabolites, which cause irritation or

allergic reactions. The bactedrium Proteus mirabilis and the yeast Candida

albicans are both capable of metabolizing urea to ammonia, which has been

proposed as a possible cause of diaper rash. The pH increase caused by the

ammonia may also irritate the skin.

Odors.

Bacterial metabolism of perspiration in moist, warm area such as

inside shoes, underarm of clothing and towels, produces the volatile molecules

such as carboxylic acids and aldehydes associated with body odor. Organisms

isolated from perspiration are those commonly found on the skin, such as S.

aureus, S. epidennidis, Corynebacterium sp. and Propionibacteria.

Fabric Deterioration

The cellulose enzymes produced by some bacteria and fungi are

capable of degrading cotton fibers, causing loss of strength, and reducing the

lifetime of the textile. Structural damage to fibers by S. aureus has been

reported Fungi may also produce unsightly staining, when pigments produced

diffuse into the fiber. In may case, these pigments cannot be removed by washing

or bleaching.

Antimicrobial

agents are chemical compositions that are used to prevent microbiological

contamination and deterioration of the commercial products, materials and

systems. Their areas of application include cosmetics, disinfectants, and

sanitizers, wood preservation, food and animal feed, paints, cooling water,

material working fluids, hospital and medical uses, plastics and resins,

petroleum, pulp and paper, textiles, latex, adhesives, leather and hides, and

paint slurries.

A given

antimicrobial agent may either destroy the entire microbe cell present

Or just prevent

their further proliferation to numbers that would be significantly destructive

to the substrate or system being protected. In sharp contrast to certain medical

situations that require complete sterility, most industrial applications demand

only that potentially destructive microorganisms are inhibited from

proliferating to a detrimental level.

Mode of Action

The mechanisms by which chemical agents exert antimicrobial activity

depend upon effective contact between the chemical and the microorganism and

involve disruptive interaction with a biochemical or physical component of the

organisms that is essential to its structure and metabolism. The targets may be

a single enzyme, a cell membrane, intercellular systems, cytoplasm, or

combinations of these and the nature

Of the action is dependent on the organisms and the

environment in which the interaction occurs as well as on the antimicrobial

agents

Some of the primary modes of

action are as follows:

Cell wall synthesis inhibitors:

Cell

wall synthesis inhibitors generally inhibit some step in the synthesis of

bacterial peptidoglycan

Cell membrane inhibitors:

They disorganize the structure or inhibit the function of

bacterial membranes. The integrity of the cytoplasmic and outer membranes is

vital to bacteria, and compounds that disorganize the membranes rapidly kill the

cells. However, due to the similarities in phospholipids in eubacterial and

eukaryotic membranes, this action is rarely specific enough to permit these

compounds to be used systemically.

Protein synthesis

inhibitors ~ Many therapeutically useful antibiotics owe their action to

inhibition of some step in the complex process of protein synthesis. Their

attack is always at one of the events occurring on the ribosome and never at the

stage of amino acid activation or attachment to a particular tRNA

Competitive Inhibitors:

The competitive inhibitors are mostly all synthetic

chemotherapeutic agents. Most are "growth factor analogs" which are

structurally similar to a bacterial growth factor but which do not fulfill its

metabolic function in the cell. Some are bacteriostatic and some are

bactericidal.

Effects on Nucleic Acids:

Some chemotherapeutic agents affect the synthesis of DNA or RNA,

or can bind to DNA or RNA so that their messages cannot be read. Either case, of

course, can block the growth of cells.

8

CLASSES OF ANTIMICROBIAL

AGENTS

Phenolics

Phenolics generally exhibit broad - spectrum activity against

Gram-positive and Cram-negative bacteria as well as against fungi. This property

plus their relatively moderate cost, make them quite cost-effective.

Phenols are considered to be moderately too highly toxic. The

chlorophenols can be absorbed through the skin in toxic levels and their dusts

are very irritating to the skin, eyes and respiratory tract. The formation of

highly toxic chlorinated dibenzop-dioxins

As

impurities in the production of various chlorophenols has been reported.

However, the acceptable products given below continue td keep the phenolic class

of antimicrobial agents among the most widely used in industry

|

NAME |

APPLICATION |

|

Pentacholoropenol |

Textile, wood and paper leather, paints |

|

Sodium pentachlorophenoxide |

Textiles, adhesives, leather, pulp and paper, water

treatment |

|

2,4,5-trichloropheno1 |

Textile, adhesives, rubber, paper mills, slim cides, leather |

|

Sodium o-phenyl-phenoxide |

Textiles, adhesives, ceramic, glazes, clay slips, paints,

floor waxes. |

Halogen compounds

The halogens constitute a class of antimicrobial agents that are

larger in commercial distribution than the phonetics. May of their applications,

e.g. swimming -pool sanitizers, household and hospital disinfectants, and

surgical scrubs are outside the scope of this article, but many industrial uses

exist, especially for a number of organic halogen derivatives.

The halogen can be

in the active or available form in which it demonstrates

antimicrobial

activity because of its oxidizing capacity through a positive valence

state. The halogen

also contributes activity as a covalent substituent of a complex structure. The

spectrum of commercial products ranges from the elements, to inorganic

hypohalites, to complex halogen -substituted organic compositions.

Iodine Compounds.

The

use of elemental iodine as antiseptic dates back to 1839 -. It is used today for

various medicinal purposes.

|

NAME |

APPLICATION |

|

p-tolydiiodomethyl

sulphone |

Textiles, paint

preservative, paint mildewcide, water based adhesives, |

OUATERNARY AMMONIUM

COMPOUNDS (OUATS)

The category

represents one of the largest, most diverse classes of antimicrobial

agents in use. Chemically, the products may be represented by the

general formula

|

|

The nitrogen atom carries four covalent bound Substituents that

give it a cationic charge. The R groups may be almost any organic substituents

that allow carbon nitrogen bonding with any permutation of like and unlike R

groups. The nitrogen atom may be part of a heterocyclic, aromatic structure,

thereby automatically fixing three substituents.

|

NAME |

APPLICATION |

|

3-(trimethoxysilyl)-propyldimethyloctadecylammonium

chloride |

Textiles |

Mercurils

|

NAME |

APPLICATION |

|

Di (phenyl

mercury)-dodecenylsuccinate (PDMS) |

Textiles, paint

preservative, paint mildewcide, |

Arsenicals:

These are used in diluted forms as could be toxic at high

concentrations. Their major

application is in plastic industry. 10,10 - Oxybisphenoxyarsine is

the only organ arsenic product of importance as an industrial antimicrobial

agent.

|

NAME |

APPLICATION |

|

10,10 -

oxybisphenoxy-arsine |

Textiles, plastics |

Organotins.

Copper Compounds.

|

NAME |

APPLICATION |

|

Copper

8-quinolinate |

Textiles,

plastics, wood |

|

Copper naphthenate |

Textiles, wood |

Anilides

Trichlorocarbanilide (TCC) is the only anilide that enjoy sizable

sales as an antimicrobial agent; it is used almost exclusively in deodorant bar

soaps. The FDA's Advisory Review Panel on over - the counter antimicrobial drug

products critically reviewed appropriate data regarding the safety of

salicylanilides and carbanilides, and found considerable evidence of

photosensitization by halogenated salicyolanilides. The toxicology has been

discussed in various articles. Subsequently the FDA placed halogenated

salicylanilides in Category2 as not safe and effective for use in drug product

and cosmetics.

|

NAME |

APPLICATION |

|

Salicylanilides |

Textiles, leather |

miscellaneous compounds.

A few antimicrobial agents are unique in their functional

classification. In general, each has one significant main use and, in most

cases, only limited market significance as an industrial antimicrobial agent.

The significant products are shown in the Table. Organic acids and their salts

constitute a sizable category among antimicrobial agents.

|

NAME |

APPLICATION |

|

2,6-dimethyl,

1,3-dioxanol-4 acetate |

Textiles |

CHOOSING

AN ANTI

MICROBIAL AGENT

·

Is claimed to combat the microorganism of

concern to the degree desired.

·

Appears

to be physically and chemically compatible with the system, i.e. will not

upset desirable physical and chemical properties of the system and

(conversely) will not be inactivated by the ingredients of the system.

·

Maintains

stability under use and storage conditions (pH, temperature, light, etc) for the

required length of time.

·

Is

safe and nontoxic in handling, formulation and use.

·

Is environmentally acceptable, and

·

Is

economically acceptable and cost-effective

Application

methods are particularly suitable:

1.Padding:

Fabric is run through a pad- bath to give approximately I% of treatment fabric

is then padded wet on -wet through a bath of approximately 0.5% Repulix, rinsed

and dried.

Other

finishes may also be applied simultaneously through slight modification of the

processing conditions may be required .Due to the wide variety of finishes

currently in use, compatibility should be tested on an individual basis.

2.

Exhaustion:

The chemical treatment exhausts rapidly from dilute aqueous solution onto

cotton. Adsorption is again improved at pH 7-8 .As in the padding application;

it is recommended that this treatment is followed by an acid fix and water

rinse. The spraying of solutions of antimicrobial active agents is not normally

recommended, due to the risk of the production and subsequent inhalation of

droplets of respirable size. Nevertheless, the treatment can be applied by

spraying, provide, suitable containment facilities are available; this method is

particularly suitable for non-woven fabrics.

Chito-oligo

saccharides as antimicrobial agents for cotton

Cotton fabric with good antimicrobial activity and durability to

washing is obtained by using chito-oligosaccharides without the need for a

binding chemical as a crosslinker. The fully deacetylated chitosan is

depolymerized into chito-oligosaccharides using sodium nitrite. The average

degree of polymerization (DP) of chito-oligosaccharides is determined by

calorimetric titration of a terminal aldehyde group of chito-oligosaccharides.

In a pad-dry-cure process, two different chito-oligosaccharides (DP = 3 and 10)

are applied to cotton fabric using the chemical reactivity of the terminal

aldehyde group. The antimicrobial activity and durability to washing of the

treated cotton are evaluated. The results show that at the fiftieth wash cycle,

the cotton fabrics treated with 2.4% chito-oligosaccharides are able to maintain

95% (for a DP of 3) and 100

Pre-treated

cotton/polyester fabric

Cotton/polyester fabrics containing cross-linked polyethylene

glycols (PEGs) show antimicrobial activity against a diverse group of bacteria

and fungi. The PEG-treated fabrics have substantial resistance to most

microorganisms relative to untreated fabrics. Because the level of formaldehyde

is extremely low, it is hypothesized that the antimicrobial activity of the

modified fabrics is due to a unique combination of physical and physicochemical

effects. These may include the hydrophilic nature of the cross-linked PECs that

desiccate microbes and deprive them of needed moisture and/or absorption and

release of latent heat by the bound PEG. However, the most probable effects that

impeded microbial growth may be attributable to the surfactant like properties

of the bound PEC, which disrupt cell membranes due to the dual

hydrophilic-hydrophobic characteristics of the PEGs.

Most finishing

methods directly use biocides in the finishing solutions and the biocidal;

function is achieved by controlled release or consuming the biocides combined on

the fabric. Therefore the imparted function will diminish as soon as the

biocides vanish from the fabrics, yielding a nonregenerable finish. The

traditional method has been an obstacle to achieving durable functional fabrics.

In the new process, precursors of biocidal compounds were utilized instead of

the biocides themselves in the treatment of cellulosic materials, and covalent

bonds established between the agent and fibres before the biocidal sites are

activated. The chemical structure ands of the finished fabrics and and their

relationship with the properties have been explored. In this section chemical

structures of MDMH treated fabrics are discussed. Structure property

relationships

analyzed.

The chemical

structure can be analyzed by:

·

Identification by FITR

·

Nitrogen analysis

·

Chlorine analysis

Chemical identification by FITR: Hydantoin compounds have two prominent bends at 1720 and 1770

cm-1. Thus bends at these wavenumbers can be used as indications of the

hydantoin structure grafted on to the fabric. Intensities of bend vary according

to the concentration difference of MDMH in the finishing baths. The

characteristics of the band are consistent with the structures of the products,

providing direct evidence of the structures, and can be used to quantitavely

analyze grafting rates of the chemical treatment.

Nitrogen analysis

The chemical

structures of treated and chlorinated fabrics can also be characterized using

elemental analysis, such as nitrogen and chlorine. Pure cotton fibres are mainly

cellulose and carbohydrates, containing undectable amounts of nitrogen. Thus

nitrogen contents of treated cotton fabric can be used as reference for the

amount of hydantoin groups grafted into cotton fabrics.

Chlorine analysis

After chlorine

bleaching, the treated fabrics will contain active chorine in the halamine form.

The active chlorine bonded on nitrogen, a halamine bond, is extremely polar in

the covalent bonds possessing partially positive charge. It is this chlorine

that can oxidize man organic structures in proteins or in some organic compounds

resulting in the inactivation of microorganisms. After the oxidation, the

chlorine atom is reduced to chloride and the halamine bond reverts to a N_H

bond. Because of the oxidative ability of the chlorine, its content on the

fabrics can be analyzed by using the iodometric titration method .The chlorine

contents on cotton and polyester/cotton fabrics treated with three different

concentrations of MDMH varied after repeated washing not only relying on the

concentrations of of MDMH in the finishing baths. (Graph below)

The Biocidal

properties of the fabrics are achieved by two steps of chemical processing

including finishing under acidic conditions and rinse with chlorine bleach. Each

of the process may have its on impact on physical properties of the fabrics.

Thus whether how much the treated fabric can retain its original tensile

strength at different finishing conditions is important. Factors, which may

affect the mechanical properties of the fabrics, are: Finishing

concentrations PH value Chlorine

concentration Drying conditions Effect of finishing concentrations: The amount or concentration of chemicals on the materials or

so-called add-on rates, will certainly affect the effectiveness of the function.

A higher concentration of finishing bath help to achieve a better adds on rate

on the fabrics thus improving the add-on properties. However, it also damages

the tensile strength of the material more substantially than lower

concentrations of finishing bath do. The graphs below show this effect on pure

cotton and polyester cotton blend

tensile strength retention of

tensile strength retention of

polyester/cotton blends treated

with MDMH

pure cotton treated

with MDMH

Thus polester cotton

blend having 35% cotton are less vulnerable to acidic conditions and

concentrations of finishing conditions Effect of pH values of finishing bath: The finishing of MDMH on cotton fabrics is carried out under low

pH conditions. Cellulosic structures are unstable to this condition because of

rapid decomposition of the chains catalyzed by the low pH. Following table shows

effect on fabric with varying pH concentrations.

As pH values

increase the physical properties of the fabric improve considerably. Effect of chlorine concentrations Chlorine solution being strongly oxidative

serves as the activating and regenerating agent in treatment. Chlorine was

considered very harmful to the functional moieties on the cellulose. Thus

chlorine concentrations were varied to examine the influence of chlorine damage

to the treated fabrics

Antibacterial Test Methods. Methods for

evaluating the effectiveness of an anti-bacterial finish on fabrics have been

the subject of much debate. Nevertheless, industry standard methods have been

developed by bodies such as AATCC, in the US, and SEK in Japan 8.9 Example of

this method are the AATCC 100 and the SEK

bacterial count methods. AATCC

test Method 100:

Four pieces of staked circular fabric swatches 4.8 + 0. I cm (about one gram)

are inoculated with O + 0. 1 ml of inoculum in a 250 mL jar. The inoculum as a

nutrient broth culute contains over I.O X 10^6 clone forming units (CFU) of

organism. After the swatches are inoculated, they are neutralized by 100 ml Of a

0.2% sodium thiosulfate solution in the jar. The contact time was the interval

between inoculation and neutralization. The jar is vigorously shaken and the

neutralized solution is diluted in serial. The dilutions, usually 10^0,10^1,

10^2 are plated on nutrient agar and incubated for 18-24 hours at 340C. The

numbers of bacteria recovered from the incubated finished fabrics are counted

and compared with that of untreated fabrics. SEK bacterial count : In this method 0.2 mi of a S. auresu suspension is inoculated

onto a 2 cm square of test fabric, and incubated at 370 for 18 hours 20 min

neutralizer solution is added, and the surviving bacterial counted using a

serial dilution pour plate technique. This method is considered to be the most

representative of a garment or

bedding

exposed to perspiration and bacterial contamination. In this test, a large

bacterial inoculum was used typical of that which has been found for example on

socks. Antifungal

Test Methods The assessment of

the antifungal activity of textiles is also by an agar plate method. A

suspension of fungal spores is inoculated onto the surface of an agar plate, the

test material placed on the agar, and further inoculum distributed over the

material. The samples are then incubated, and the surface area of fabric covered

with fungal growth visually

assessed. A " zone of inhibition" may be observed if the antifungal active agent can

leach from the fabric into the textile. A typical method is AATCC Test method

30. Assessment of durability It is essential that the antimicrobial effect last throughout the

normal lifetime of the product, which has been treated. The durability required

will vary, according to the lifetime of the article, exposure and washing

conditions. The tests has been based on two types of cycles: 1.Domestic wash cycle

Synthetic

detergent 4.5g/l Sodiurn

metasilicate 3.1g/l Hypochlorite

bleach 1.5g/l Wash at 45C, 15 min., rinse at 40C, and 10 min. Tumble dry at

800C, 12 MIN 2.Professional wash cycle Synthetic detergent

4.5g/l Hydrogen peroxide

3.1g/l Sodium percarbonate

1.5g/l Wash at 80C, 15 min. Rinse at 40C, IO min. Tumble-dry at 80C, 12

min. Each wash cycle considered as 5 washes in practice.

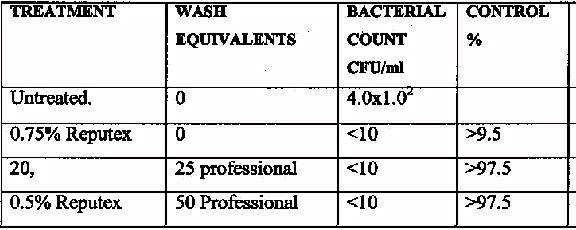

Anti bacterial

effect after domestic washing cycle

It is very common to find cotton or cellulose textiles with odors,

particularly if they are kept in a damp or soiled condition. For example a towel

will develop a musty, mildew odor if left damp or in a humid environment such as

bathroom. Clothing may develop characteristic foot or body odors .in the

majority OF vases these odors are generated by the action of microorganisms such

as bacteria or fungi. microbial odor generation on cotton or cellulosic textiles

can e controlled by treating the textile with a finish that in=impacts a durable

antimicrobial activity. The characteristic body odor is thought to be from 3-methyl-2

hexanoic acid produced by the species of Staphylococcus epidermis and

Corynrbacterium sp. Foot odor is quite different, and contains low molecular

weight carboxylic acids. This may be because different microorganisms prefer the

warm, moist conditions around the feet. Other odor molecules such as aldehydes

and amines may also be generated .A widely studied system is the break down of

urea into ammonia, by bacteria which secrete urease enzymes. This is of

particular importance in babies’ diapers, where ammonia generation gives a

pungent odor and also an increase indicated in nappy rash.

An investigation has been carried on poly (hexamethylene biguanide

hydrochloride)(PHMB), the basis of Reputex 20, an antibacterial that does appear

particularly suitable for cotton and cellulosic textile. It has been used for

some tears in a variety of antibacterial applications with high human contact,

such as swimming pool sanitization and preservation of personnel care products

However it is recently only that applications of this molecule on textile

industry have been developed. It is a relatively safe molecule and has low mammalian toxicity.

It shows good antimicrobial activity against broad spectrum of bacteria, yeasts

and fungi, and has a low environmental impact since it contains no heavy metals,

formaldehyde, organic halogens

15

16

EFFECT

OF ANTIMICROBIAL FINISHES ON MECHANICAL PROPERTIES

17

Based on

concerns of chlorine damages to the Biocidal properties, lower concentration is

preferred in both activation or regeneration process.

Based on

concerns of chlorine damages to the Biocidal properties, lower concentration is

preferred in both activation or regeneration process.18

ASSESSMENT OF

ANTI-MICROBIAL FINISHES

19

20

21

ANTIODOR FINISHES

22

The following tables

show observations of some experiments carried out.

.

There are two methods commonly used to reduce the spread of

microorganisms. Repellent finishes are popular in consumer goods because they

allow the fabric to “breathe” by allowing the passage of air through the

fabric while preventing the fabric from getting wet. Although this method has

shown a reduction in the transmission of microorganism, some may still be

transferred through the fabric or be transmitted from one area to another. Hence

the other method is to treat the fabrics with antimicrobial finishes that kill

microorganisms or inhibit their growth if microorganism comes in contact with

the fabric surface or if they are transmitted through the fabric. Therefore the

presence of live microorganisms is reduced, resulting in reduction of

microorganism transfer.

Application

of chemical finishes

Chemical finishing steps involves application of chemical solution

by padding, removing of water, curing the fabric after drying .The fabrics are

exposed to solution containing the antimicrobial finishes using Cromax

laboratory padder. The roller pressure is set to 60psi. Each fabric is padded

twice to ensure even distribution of the solution.

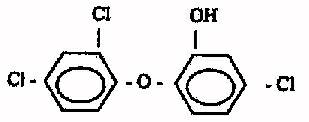

Triclosan is chlorine phenoxy compound that interrupts cytoplasmic

membrane and interfere with the metabolic functions of cell. However it is

incapable of rupturing the cell membrane of thicker blood cells, so it is safe

for human and animal contact.

triclosan

REFERENCES

1. A

New Durable Antimicrobial Finish For Cotton Textiles

American Dye stuff Reporter; May 1996 (26-30)

2. Industrial

Antimicrobial Agents

Encyclopedia Of Chemical Processing; Volt 13; 1965 ;(223-253)

3. Durable

And Regenerable Antimicrobial Finishing Of Fabrics: Biocidal

Properties; Textile Chemists And Colorists; Vol 30; June 1998; (26-30)

4. A Durable

Antiodor Finish For Cotton Textiles

Textile Chemists And Colorists; Vol 28; May 1996; (28-300)

5.

Preparing Chito-Oligosaccharides As Antimicrobial Agents For Cotton

Textile-

Research-Journal. 1999; 69(7): 483-488.

6.

Antimicrobial textiles; ITB International Textile Bulletin 5/2000

7. Durable

And Regenerable Antimicrobial Finishing Of Fabrics: Biocidal

Properties; Textile Chemists And Colorists; Vol 31: May 1999

8.

Durable And Regenerable Antimicrobial Finishing Of Fabrics:

Chemical

Structure;

Textile Chemists And Colorists; Vol 30; June 1998; (31-35)

9.

Durable And Regenerable Antimicrobial Finishing Of Fabrics: Fabric

Properties; Textile Chemists And

Colorists; Vol 30; June 1998; (21-24)

10.

One-Bath Application of repellent and Antimicrobial Finishes to Nonwoven

Surgical Gown Fabrics.; Textile Chemists And Colorists; Vol 31:

March

1999; (11-16)

11.

New approach for imparting antibacterial activity to cellulose-containing

fabrics;

COLOURAGE; July 1998;(13-19)