DUCKZILLA

by John Hazel

Here's the situation that inspired me to write Liftroll.xls:The Duck is a loved and hated RC sailplane. Some swear by the design it and others swear at it. The overall performance is excellent but there are some performance pitfalls that are related to it's simple planform and low aspect ratio. The key to getting great flights out of this design is to be aware of the ship's character. For example, if you fly near stall speed the sink rate can get pretty bad. Fortunately the solution to this problem is simple. Flying just a little faster gives a very large improvement in sink rate. Although the solution to the slow speed sink problem is simple, implementing it is not easy for everyone. The reason for this difficulty is suprisingly related to one of the Duck's excellent qualities: crisp low speed handling. It takes a little thought to understand the situation. Beyond some distance, and without a good visual reference, an RC glider pilot tends to sense airspeed by how the ship responds to control input. When the controls get "mushy" he knows that the glider is flying near stall. The Duck's good handling at slow-speed, high-sink, flight conditions fools some pilots into thinking they are flying well above stall when he is actually flying on the edge of stall. The fooled pilot's flight time usually reflects the high sink rate of a wrongly flown Duck.

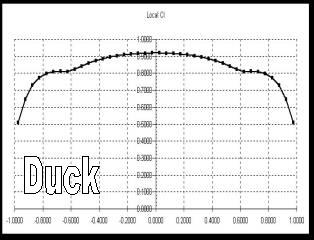

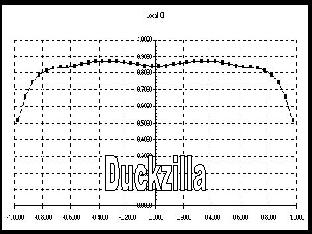

A look at the coefficient of lift (Cl) distribution for the Duck planform reveals the cause of it's high-sink and crisp handling at low speeds. The wing does not have much taper so the Cl at the center of the span is much higher than the average Cl. This makes it possible to stall the center of the wing without stalling at the aileron. This stall tends to stay at the center of the wing over a fairly large range of angle of attack (AOA). So it is clear that on low or no taper wings it is possible to fly around with the center section stalled while still retaining good aileron response. To get rid of this deceptive flight behavior the wing taper (or root chord) could be increased. The question then is: How much change in taper should be made?The stock Duck 2 meter wing has a 10" chord straight inner panel that is 24" long. From there the wing tapers to 7" at the tip. One modified Duck (Duckzilla) planform has the root chord increased to 12". It is clear that much more of the wing can reach a high Cl before any part stalls. This is achieved while still retaining a reasonable tip stall margin. In practice Duckzilla did float noticeably better that a stock 2m Duck but landing approaches could not be made with reckless abandon (which is possible and often practiced by pilots of stock Ducks) due to greater potential for tip stall.

DUCK

|

DUCKZILLA

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||