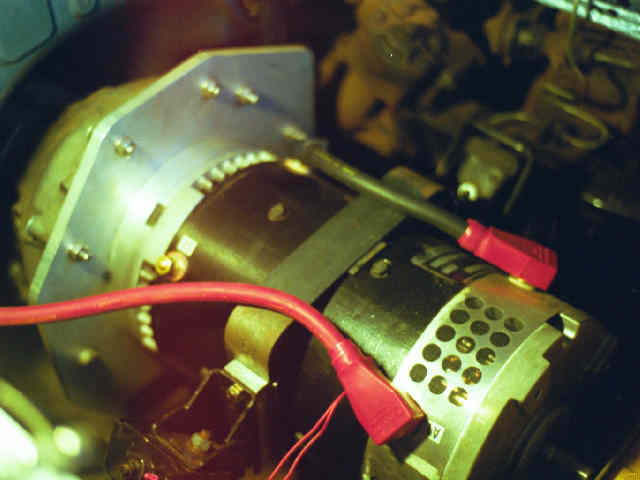

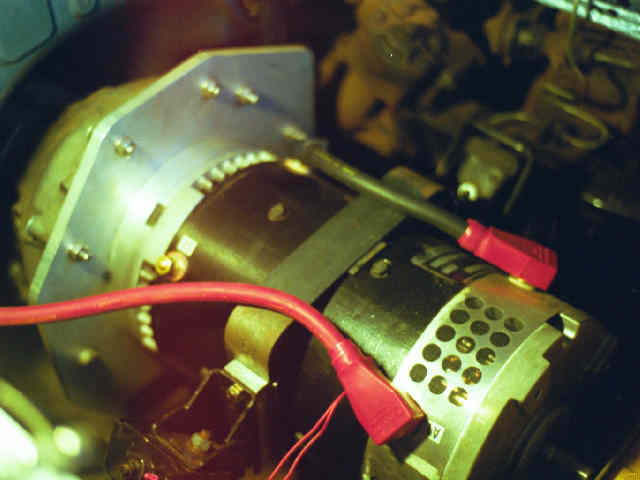

The motor bolted to the original motor mounts and ready to go! The homebrew

motor mount across the middle of the motor was made from

1/8 inch thick, 2 inch wide steel strap

and lots of bending. The bottom half is bent in a semi-circle shape under

the motor. The large aluminum adapter plate at the left of the

picture was made by a machinist to 2/1000ths of an inch tolerance to ensure

proper centering of the motor on the transmission input shaft (it turns out it

needs to have better tolerance than that). The bolt just

above the red wire has been replaced with an SAE grade 8 hardened bolt to hold

the torque bar to the frame. The torque bar is made from a piece of 1 inch

angle stock left over from a rear battery box bracket and is not shown in this

picture. The two small red wires are from the motor temperature sensor switch

and are now wired directly to the old 'oil pressure' light (the other wire to ground).

Keep the clutch! I am not pleased with the clutchless design and

everyone I have talked to has said they want a clutch in their next

conversion. Although shifting is rarely necessary, shifting

is not very easy and its hard on the synchros in the tranny. The major

recommendation against clutchless was explained by a local machinist

and EV converter. Its nearly impossible to make the required alignment

between the motor and transmission input shaft. The tranny just isn't

designed for it.

If you decide on a clutchless coupling anyway, you MUST use a new

clutch disk. My only breakdowns came from the old clutch disk with 128k

miles on it coming apart due to the major misalignment caused by the slack

in the center piece.

PICKUP PAGE