- Cheap, its virtually free

- Increases spring rate, should improve handling

- Exact drop is unknown until truck is reassembled

- Ride will be rougher, due to increased spring rate

- Truck will bottom out sooner, due to shorter distance to the bump stops

- Care must be taken when cutting, to prevent the spring from getting to hot, and the temper being removed and weakening the spring.

- Relatively inexpensive

- Increase in spring rate, should improve handling

- Choice of constant rate, or progressive spring rate coils

- Ride will be rougher, due to increased spring rate

- Truck will bottom out sooner, due to shorter distance to the bump stops

(1983-1997)

- Factory ride is maintained

- Most expensive, non-adjustable method

- Rather labor intensive

(1998+)

- Factory ride is maintained

- Most expensive, non-adjustable method

- Rather labor intensive

- If the 3" drop from a set of I-beams isn't enough, you can combine the I-beams with shorter springs to get you 5" lower. Any lower than that, and you probably won't be able to get it aligned.

- Speaking of getting it aligned, to straighten the camber out on a I-beam ranger, you have to replace the camber bushing, sometimes referred to as a "slug". Most alignment shops use bushings that aren't adjustable, so you need a new bushing for every adjustment. That's why it usually costs more to align a Ranger, its that "plus parts" clause. Well, there are aftermarket, adjustable bushings available so they may be a good investment if you think you are going to be needing realignments, and with expensive low profile tires, its a good idea.

- Watch the offset and width of your wheels on the pre 1989 Rangers too. The top of the wheel well in the fender is pretty low, so you don't want it to make contact with your tires when you hit a bump. Ford Probe wheels bolt right up, and will allow you to "tuck tire".

- If you want to make the height adjustable, you can use hydraulics, or air bags. See more on these options below.

- You should not cut the front bump stops, because they keep the tierod from hitting the frame.

- If you go lower than 2" you should also get new shocks, since the lowered suspension will put your factory shocks in compression. Make sure you get shorter shocks.

- Constant rate VS. Variable (or progressive) rate Springs

- For a comfortable ride, you want a "soft" spring, or one that will allow easy movement of the suspension. But, for load handling, and performance driving, you don't want the spring compressing too much, or you will bottom out, or cause excessive suspension travel.

- A constant rate spring will give you the same amount of resistance to compression, all the way until it is fully compressed. So, if the spring is soft, you will have a comfortable ride, but it may not hold as much weight, or handle as well. And, if the spring is too stiff, the ride may be harsh, and handling may suffer as well, due to lack of suspension travel, but you will be able to carry a heavy payload. So, you may have to find a happy middle ground, and compromise some ride for payload or handling characteristics.

- A variable or progressive rate spring is the spring designers compromise between a soft comfort spring, and a stiff payload spring. It works like this, one portion of the spring has the windings spaced farther apart, and they get closer together, as you near the other end of the spring. This way, when the spring initially starts to compress, it is easy, and "soft", but as the compression continues, the spring gets stiffer. With a progressive spring, you *should* get comfort, handling, and payload capabilities.

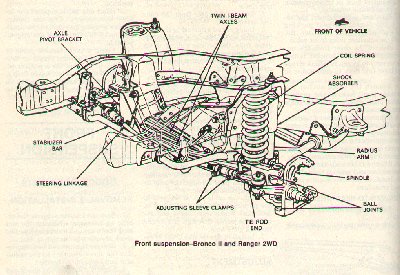

- Front suspension images: