Links

Matts Home Made CNC Machine

-----

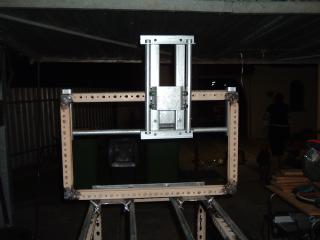

XYZ Rails 22-12-2005 Now I've got both the XYZ Rails in place. On to the next part of stepper motor control.

|

X Rails 18-12-2005 Now I've got both the X Rails in place and I'm well on the way to making the other axis's.

|

First Weld 21-9-2005 This would be my first weld with my new welder, as you can see i'm not a welder by trade.

Now all my efforts paid of.. A table to put all my CNC stuff onto. I still need to do some more work but I'm happy with the results.. Still room for improvement.

|

Welder 20-9-2005 Today I went and bought a welder to help me out with this CNC project.. It's a no frills stick welder and came complete with a hammer, brush and mask.. Looks like I've got something to do in the comming days... |

Z Axis Test 19-9-2005Today I gave the Z axis a test run. Not happy with it. I'm thinking I'll just have to go down the heavy duty path. My construction method is not so crash hot and as a result I get a trasfer of any play in the threaded rod to the Z axis frame. |

To Far 17-9-2005 Maybe I have gone to far but here is a picture of the bearings I will be using. . |

Bearing Bracket 17-9-2005 This will be the brearing bracket as seen around... This was folded as one piece and will allow for a number of units to be made. This was given to me by a club memeber who has built his own foam cutting machine..

.

This will be the brearing bracket as seen around... This was folded as one piece and will allow for a number of units to be made. This was given to me by a club memeber who has built his own foam cutting machine..

.

|

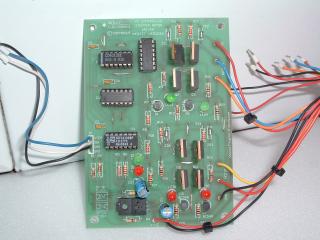

Driver Board 17-9-2005This is a kit stepper motor driver board. The problem that this kit has is that the output is only a constant voltage. The effect of a constant voltage on the stepper motor at a high switching rate is low torque. I will have to modify the board to use constant current or throw it out. .

.

|

Stepper Motor 17-9-2005Here is a great picture of the stepper motors I will be ussing for the X and Y axis.. .

.

|

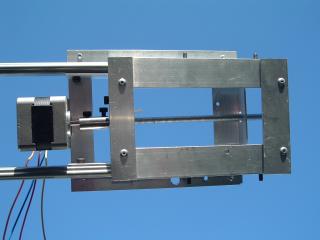

ZAxis 17-9-2005 The construction of the ZAxis is a test and uses parts off the old machine. I am trying only to use tools in my work shop to build the CNC. Things that I would like are a welder, Lathe, Drill stand, CNC :), however I'll just have to make do with what I've got at the moment. The quality of build is still not that great but I'm getting better.

The construction of the ZAxis is a test and uses parts off the old machine. I am trying only to use tools in my work shop to build the CNC. Things that I would like are a welder, Lathe, Drill stand, CNC :), however I'll just have to make do with what I've got at the moment. The quality of build is still not that great but I'm getting better.

|

CNC Prototype 2The start of a new CNC machine 15/9/2005 |

Failed CNC Prototype 1The failed old CNC Machine

|

Why did it FailThe old machine failed for a couple of reasons.MDF got wet. The draw sides had to much play. Constant voltage stepper motor driver boards. Lack of skill in constuction |

ContactMatt Woodroffe (2005) |

Me welding, just had to put this one in :).

Me welding, just had to put this one in :).