|

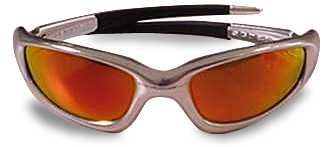

Reflective sunglasses often have a mirrored look. The lenses in these sunglasses have a reflective coating applied in a very thin, sparse layer -- so thin that it's called a half-silvered surface.

The name "half-silvered" comes from the fact that the reflective molecules coat the glass so sparsely that only about half the molecules needed to make the glass an opaque mirror are applied. At the molecular level, there are reflective molecules speckled all over the glass in an even film but only half of the glass is covered. The half-silvered surface will reflect about half the light that strikes its surface, while letting the other half go straight through. |

|

|

Often, the mirror coating is applied as a gradient that gradually changes shades from top to bottom. This provides additional protection from light coming from above while allowing more light to come in from below or straight ahead. What that means is that if you are driving, the sun's rays are blocked but you can see the dashboard. Sometimes the coating is bi-gradient, shading from mirrored at top and bottom to clear in the middle. The key problem with reflective sunglasses is that the coating is easily scratched. Apparently, sunglass manufacturers have not been able to successfully apply a scratch-resistant layer on top of the reflective coating. Therefore, the scratch-resistant coating is applied first to protect the lenses and the reflective coating is applied over it. |

|

|

Photochromic lenses have an adjustable tint that changes with the amount of available light. In bright sunlight they darken; when light conditions are not as bright, they lighten in color. Note that the photochemical response does not happen instantaneously. It normally takes (on average) one to two minutes for photochromatic lenses to adjust from very low levels of light to very bright and vice versa. Also, the tint change is usually not very dramatic. Photochromatic lenses usually range from 10% light transmission in bright light to 20% light transmission in low light. A difference of 10% transmission is not always noticeable, but over long periods of time, you should notice a significant reduction in eye strain. As a general rule, photochromatic lenses are almost always glass lenses due to the nature of the photochemical application process. Hobie make a photochromic-polarized lens, while Serengeti makes all of their Drivers lenses photochromic. Sunglasses or prescription eyeglasses that darken when exposed to the sun are called photochromic, or sometimes photochromatic. Developed by Corning in the late 1960s and popularized by Transitions in the 1990s, photochromic lenses rely on a specific chemical reaction to UV radiation. Photochromic lenses have millions of molecules of substances, such as silver chloride or silver halide, embedded in them. The molecules are transparent to visible light in the absence of UV light, which is the normal makeup of artificial lighting. But when exposed to UV rays in sunlight, the molecules undergo a chemical process that causes them to change shape. The new molecular structure absorbs portions of the visible light, causing the lenses to darken. The number of the molecules that change shape varies with the intensity of the UV rays. When you go indoors and out of the UV light, the reverse chemical reaction takes place. The sudden absence of UV radiation causes the molecules to "snap back" to their original shape, resulting in the loss of their light absorbing properties. In either direction, the entire process occurs very rapidly. In the PhotoBrown and PhotoGrey products made by Corning in the '60s, the lenses were made of glass, and the molecules are distributed evenly throughout each entire lens. The problem with this method became apparent when it was applied to prescription glasses, in which different parts of the lens can vary in thickness. The thicker parts would appear darker than the thinner areas. But with the increasing popularity of plastic lenses, a new method has been developed. By immersing plastic lenses in a chemical bath, the photochromic molecules are actually absorbed to a depth of about 150 microns into the plastic. This proved to be much better than a simple coating, which would only be about 5 microns thick and would not provide enough molecules to make the lenses sufficiently dark. This plastic lens absorption process has been popularized by Transitions, the leading manufacturer of photochromic lenses. Important

Note on Photochromics |

|

|

How Do Polarized Lenses Work? : Light reflected from surfaces like a flat road or smooth water is generally horizontally polarized. This horizontally polarized light is blocked by the vertically oriented polarizers in the lenses. The result: a reduction in annoying and sometimes dangerous glare.

Light waves from the sun, or even from an artificial light source such as a light bulb, vibrate and radiate outward in all directions. Whether the light is transmitted, reflected, scattered or refracted, when its vibrations are aligned into one or more planes of direction, the light is said to be polarized. Polarization can occur either naturally or artificially. You can see an example of natural polarization every time you look at a lake. The reflected glare off the surface is the light that does not make it through the "filter" of the water, and is the reason why you often cannot see anything below the surface, even when the water is very clear. Only the part of the light wave that is not aligned with the slots in the filter can pass through. Everything else is absorbed. The light coming through the filter is considered polarized. Polarized filters are most commonly made of a chemical film applied to a transparent plastic or glass surface. The chemical compound used will typically be composed of molecules that naturally align in parallel relation to one another. When applied uniformly to the lens, the molecules create a microscopic filter that absorbs any light matching their alignment. Most of the glare that causes you to wear sunglasses comes from horizontal surfaces, such as water or a highway. When light strikes a surface, the reflected waves are polarized to match the angle of that surface. So, a highly reflective horizontal surface, such as a lake, will produce a lot of horizontally polarized light. Therefore, the polarized lenses in sunglasses are fixed at an angle that only allows vertically polarized light to enter. You can see this for yourself by putting on a pair of polarized sunglasses and looking at a horizontal reflective surface, like the hood of a car. Slowly tilt your head to the right or left. You will notice that the glare off the surface brightens as you adjust the angle of your view. A lot of sunglasses advertised as polarizing actually are not. There's a simple test you can perform before you buy them to make sure. Find a reflective surface, and hold the glasses so that you are viewing the surface through one of the lenses. Now slowly rotate the glasses to a 90-degree angle, and see if the reflective glare diminishes or increases. If the sunglasses are polarized, you will see a significant diminishing of the glare. |

|

|

While glass is naturally scratch resistant, most plastics are not. To compensate, manufacturers have developed a variety of ways to apply optically clear hard films to the lens. Films are made of materials such as diamond-like carbon (DLC) and polycrystalline diamond. Through a process of ionization, a thin but extremely durable film is created on the surface of the lens. See Patent 5,268,217 for details. |

|

|

A common problem with sunglasses is called back-glare. This is light that hits the back of the lenses and bounces into the eyes. The purpose of an anti-reflective (AR) coating is to reduce these reflections off the lenses. Similar to a scratch-resistant coating, AR is made of a very hard, thin film that is layered on the lens. It is made of material that has an index of refraction that is somewhere between air and glass. This causes the intensity of the light reflected from the inner surface and the light reflected from the outer surface of the film to be nearly equal. When applied in a thickness of about a quarter of light's wavelength, the two reflections from each side of the film basically cancel each other out through destructive interference, minimizing the glare you see. AR coatings are also applied to the front of prescription eyewear and some sunglasses to eliminate the "hot spot" glare that reflects off the lens. |

|

|

Several of the most serious eye problems can be linked to one cause: UV light. UV is often separated into two categories based on the frequency and wavelength of the light: UV-A and UV-B. As a natural protection mechanism, the cornea of your eye absorbs all of the UV-B and most of the UV-A light. But over time, this absorption can lead to cataracts. And the small amount of UV-A that gets past your cornea can eventually lead to macular degeneration, the leading cause of blindness in people older than age 65. Intense and prolonged exposure to UV radiation can cause either cancer of the eye or photokeratitis, which is basically a sunburn on your retina. Because it occurs most often when a person is outside on bright winter day, with sunlight glaring off the snow, this condition is commonly known as snow blindness. A good UV coating on your sunglasses can eliminate UV radiation, and you should check to make sure that your sunglasses filter out 100 percent of both types of UV rays. There should be a statement on the label telling you how much UV protection the sunglasses have. You want 100-percent protection. |