| Notice that the machined area that actually makes up the seat is skirted

by a casting ridge. That ridge looks like it doesn't do anything

for you, and my initial thought was to knock it down and use the springs

that came with the LT4 kit. That would have been the wrong move because

those ridges actually keep the springs centered on the seat. My next

plan was to take the heads down to the machine shop and have the seats

machined to fit the LT4 springs. That would have worked fine, but

my machine shop told me that I'd be wasting time and money and that he

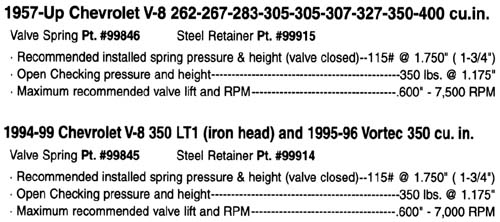

had some stock diameter springs that would work even better. I had

the heads with me, so they figured out the installed height and everything

and put their springs on the tester and found that the were 100# on the

seat and about 350# on the nose, which was better than the LT4 springs

which were 101# and 300# respectively. They also looked at coil bind

and everything, so I was convinced. The other question I had was

"why don't the LT4 springs or the original springs have dampers?"

The machine shop owner said he didn't know and that they'd be better springs

with the dampers, which seemed logical to me. So I said "great" and

walked out of there thinking I was all set ... but that's where the problem

really started.

In retrospect, I really should have started to suspect something when

I got the motor back together and I had a sort of "creaking" noise when

I turned it over by hand. I didn't think much of it at the time because

I just blindly trusted that the guy at the machine shop was right - bad

idea. Got the motor back in and started it up and noticed that the

valvetrain was awfully noisy, so I emailed Pat Flavin who has a 9C1 with

almost the exact same setup I have now (in fact I pretty much stole his

set of mods all together) and he confirmed that the GMPP roller rockers

are just noisy. Mine probably was even more noisy because of the

gear drive, so I was 99.9% satisfied that everything was OK. I went

out the the strip the next friday to make some runs and it was very consistent

- until the last run when I dropped 1/10th and heard something that sounded

a little funny at my 6200 RPM shift point. Went back to the pits

and the motor sounded fine, but I decided to knock it off and go home.

The next day I went into the shop and pulled off the valvecovers and here's

what I found: |