Titanium

Titanium is a metal that is gaining importance in the present day due to its wide applications. Pure titanium is too soft and ductile to serve many uses.

Pure Titanium

Alloys of Titanium

However, the addition of metals, such as aluminium, tin and vanadium, creates lightweight, structural alloys with excellent stiffness, exceptional strength-to-weight ratios, and great reliability at elevated temperatures and a high degree of corrosion resistance.

Titanium alloys, because of their superior qualities, have uses that span from aviation and aerospace to orthopedic implants and to golf clubs.

Shaped Memory Alloys

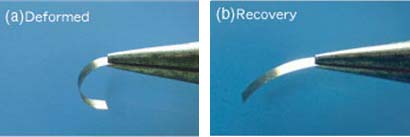

As the name suggests, shaped memory alloys are alloys which are able to regain its original shape, after it had been manipulated, when they are exposed to their transition temperature.

Shaped memory alloys are a special class of alloys which not only change phase on cooling or heating but have the particular characteristic of a low temperature phase which gives the appearance of increased ductility. It also produces a 100 times greater thermal movement than standard metals. The metal is divided between two phases - the high temperature phase and the low temperature phase. The change in phase between the high temperature phase and the low temperature phase results in a transformation between a body-centered cubic structure called the austenite and a highly twined martensite structure.

The higher temperature austenitic structure has the characteristic stress-strain curve of most metals while the lower temperature martensitic structure has a stress-strain curve more like that of an elastomer in which there is "plateau" stress. When we cool the alloy, it becomes martensitic and mechanical deformation of the alloy can take place. If it stays cold, the deformation remains but if we warm it, the austenitic structure reappears and the alloy returns to its original shape. This leads us to another unique property of shaped memory alloys - superelasticity. If the alloy is deformed at a temperature slightly higher than its transition temperature, it springs right back into shape and this is known as superelasticity.

One extremely popular shaped memory alloy is Nitinol, an alloy of nickel and titanium in almost equal quantities. Nitinol is often shaped into wires. When heated, the wire contracts in length but its cross-section increases to keep the volume constant. Nitinol wires are often used in orthodontic archwires in braces. The nitinol wire provides a low constant force at human body temperature used to straighten teeth while reducing the need for wire retightening.

NiTi wires for frames of spectacles and as Arch Wires

Also, due to the linear contraction of the nitinol wires which resembles that of human muscle, there is currently much research in the development of prosthetic limbs which will make use of nitinol wires. If the research is successful, the new prosthetic limbs will give new lives for the millions of unfortunate people who are presently handicapped.

Presently, high-tech legs have been manufactured from a combination of many alloys. Knees and ankles of light titanium alloys are used together with shins of carbon fibres and sockets of polyethylene.

Roger Charter running with prosthetic legs, with the knees and ankles made of light titanium alloys.