Contributed by: Spliffco, Inc.

For some reason growlight manufacturers are completely ignoring

the small, personal grower. A quick look around Overgrow and you

can see some very respectable bud being grown under 150's, and

even 70 watt HPS lights. But the smallest ready made remote

ballast growlight you can buy is a 250 watter, and they usually

cost well over $150 (US).

So, as usual in the medicinal herb growing world, you need to

take matters into your own hands.

Here’s how to turn a 150 watt HPS security light available

at most Home improvment stores, into a nice remote-ballast grow

light.

Materials & Tools:

MATERIALS

Regent GT150H, (About $79)

Heavy Duty extension cord of suitable length

One heavy duty grounded electrical plug end (male)

Electrical box

Electrical box plate

Romex cable connectors (3)

Wire nuts

Bolts, nuts washers

Strip of metal to secure ballast

Project case from Radio Shack ($6.99) #270-253A

TOOLS

5/16 nut driver (for removing parts from the casing -- regular

pliers will work)

Philips head screwdriver

Regular screwdriver

Hammer

Power drill and assorted bits

Metal file

Wire cutters

Utility knife or wire stripper

Diagonal Pliers

Pliers

Remove guts

Remove the guts from the casing - bulb socket, ignitor, light

sensor socket, ballast. The ballast was glued to the casing. I

heated the casing for a couple of minutes on an oven burner

(high), and when it was getting too hot to hold, I put it on the

floor and wedged a hammer between the ballast and casing and

popped it out gently.

WIRE THE SOCKET

WIRE THE SOCKET

The socket on this particular light had some metal wiring

connectors that stuck up and made it impossible to attach to the

electrical plate without some modification (sorry no photo). Just

pull the black and white wires off of the connectors, and cut the

connectors down flush with socket base with diagonal pliers. Now

loosen the connectors (screws inside the socket), slip the wires

under them and tighten them back down. Please use some plastic

electrical tape on the end of the socket to prevent any chance of

the metal from the connectors making contact with the electrical

box cover plate.

Secure the cord in the electrical box with a romex cable

connector and wire it to the socket: black to black, white to

white, secure with wire nuts. Some electrical boxes have a green

screw inside to fasten ground wires, use that if yours has one,

otherwise fasten the green ground wire to the box using one of

the cover plate screws when you tighten the cover plate.

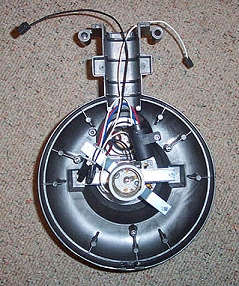

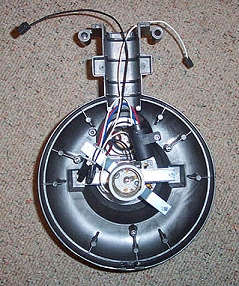

WIRE THE REMOTE BALLAST

WIRE THE REMOTE BALLAST

Hopefully you can see the wiring clearly in the photo, but if

not, refer to the wiring diagram for details.

You’re going to have to cut some holes in the Radio Shack

project box for the power cords and some bolts to hold the

ballast, ignitor and ground wires down.

I used a short length of metal (plumbing department) to secure

the ballast. The ignitor had a notch that made it easy to bolt

down. The ground wires from both electrical cords are screwed to

the base of the box.

Cut a short length off the socket (female) end of the extension

cord and wire it appropriately (again - see diagram). Wire the

remaining electrical cord, including the grounded male plug to

the other end of the box.

Use a tie wrap to bundle up the wires in the box and try to keep

them away from the ballast, which will heat up during use.

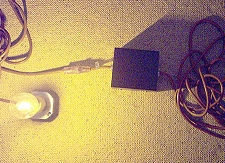

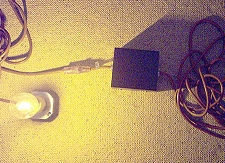

TEST IT!

TEST IT!

If you've done everything right, it should light. Now, build a

reflector and you’ve got a nice little custom grow light.

Safety Warnings:

Always wire the male plug to the bulb socket and the female

receptacle to the ballast to avoid possible electrocution! Always

use an all metal project box which already has ventilation

cooling slots, or if your project box has none, please cut

adequate cooling slots, or drill several vent holes in the

ballast enclosure (project box) to allow the heat to escape the

box. Not adding the cooling slots or holes, could result in

failure of the insulation and/or the transformer. Also, please be

sure the enclosure is located in a well ventilated area to aid

cooling.

WIRE THE SOCKET

WIRE THE SOCKET  WIRE THE REMOTE BALLAST

WIRE THE REMOTE BALLAST

TEST IT!

TEST IT!