Proprietary Technology for Encapsulation of metal clusters in “Fullerene”

Carbon Cages Produces “Magnetic Carbon with Conductive

Properties”

Interesting experiments

Sedimentation

Experiments

Material

analysis Magnets

of carbon

Mysterious magnetic fibers Properties still undetermined

Most probable structure Present day market opportunities

Applications abound

for conductive magnetic carbon some example applications include, xerographic toner and ink jet ink for

printed circuits. Other possible applications include low weight electric

motors, electric propulsion systems, catalyst, semiconductors, computer memory

storage and superconductors.

RW Industries has

developed a new proprietary process for the manufacture of carbon that is both

magnetic and conductive. This new-engineered material is available for

researchers and experimenters to investigate.

The cost for small amounts of magnetic carbon is minimal and further

reduced for university and researchers willing to share experiments and results

with RW Industries. The cost will further drop drastically when produced in

large amounts. If there is interest in purchasing these engineered materials

please call me at 216-381-3831 or email Allisonpeterallison56@yahoo.com. This technology can also be used to insert

other metal clusters into fullerene structures for catalysis, etc.

The conductive magnetic carbon (CMC) has not been fully characterized

but the material is suspected to be similar in structure to fullerenes doped with Fe, Cr, and Ni

impurities.

Experiments show the

resulting deposits of magnetic carbon pulled from suspension by a magnetic

field

Figure1

Figure2

Close up of Figure 1 shows magnetic carbon with structure due to magnetic flux field. Close up of Figure 2 shows

Again, what is believed to be a magnetic flux pattern but

pentagon and hexagon structures are unexplainable

MAGNETIC CARBON SETTLING EXPERIMENT

Figure 3

Magnetic carbon dispersed in methanol will settle out of suspension in 8.37 minutes under the influence of

gravity, while with

the addition of a magnetic field the settling time has been reduced to

2.17minutes.

If the magnet were above the container, then the magnetic

carbon would be held in suspension with out the aid of

rheological additives a new application useful to the paint

industry.

Material Identification

and Characterization

Gravimetric

analysis

|

|

Calcining

sample of magnetic carbon |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

75.80% |

carbon |

|

|

|

|

|

|

|

24.20% |

Metal or

possible trace metal oxides |

|

|

|

|

|

|

|

100.00% |

|

|

|

|

|

|

|

This

analysis may have some error due to trace amounts of steel in sample |

|

||||||

|

(Steel is

Fe,Ni,Cr) |

Due to

this possible error the carbon level is slightly increased |

. |

|||||

|

Other

analysis problems may also bring the carbon content to as high as 83.06% |

|||||||

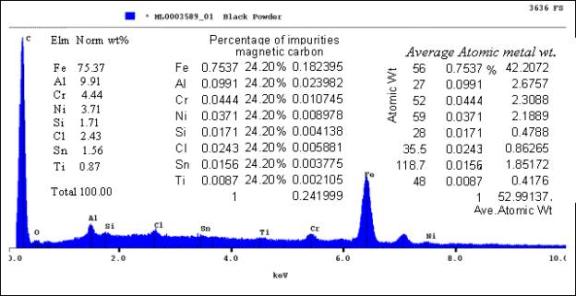

SEM-EDS analysis

The analysis work was accomplished with Energy Dispersive Spectrometer (EDS) where X-ray back scattering of heaver elements distinguishes heaver metal elements from the lighter ones.

The

resulting analysis data indicate fullerene structures

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

Fullerenes are |

C28,C32.C50,C60,C70,C76,C78,C84,C240,C540 |

|

|

|

|

|

|

|||||

|

|

Empirical

formula calculations |

#1 |

|

|

|

|

|

|

|

|

||

|

Percent

carbon |

|

75.80% |

|

|

|

|

|

|

|

|

|

|

|

Atomic Wt

of Carbon |

12.011 |

|

The basic

ratio for the chemical structure for fullerenes with: |

|

|

|||||||

|

number of

atoms per molecule |

6.310882 |

|

|

13.81874 |

carbon

atom to one metal atom |

or 14

carbon atoms |

|

|||||

|

|

|

|

|

|

structure

that would fit this molecule are: |

|

|

|

|

|||

|

%Metal

Element |

|

24.2 |

|

3XC6,2XC5 |

5XC6,8XC5 |

14XC6,0XC5 |

|

|

||||

|

Ave

Atomic Wt |

|

52.99 |

|

C28 |

|

C70 |

|

C84 |

|

|

|

|

|

number of

atoms per molecule |

0.45669 |

|

2metal

atoms |

5metal

atoms |

6metal

atoms |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

largest possible error due to metal impurities would result in the following: |

|

|

|

|

|

|||||||

|

component

metals for the average atomic weight |

|

|

|

|

|

|

|

|

||||

|

|

Empirical

formula calculation#2 |

|

|

|

|

|

|

|

|

|

||

|

Percent

carbon |

|

83.06 |

|

|

|

|

|

|

|

|

|

|

|

Atomic Wt

of Carbon |

12.011 |

|

Structures

that fit are |

|

|

|

|

|

|

|||

|

number of

atoms per molecule |

6.858794 |

|

14XC6,0XC5 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

C84 |

|

|

|

|

|

|

|

|

percentage

of metal |

|

16.94 |

|

4 metal

atoms |

|

|

|

|

|

|

||

|

Average

Atomic metal Wt |

52.99 |

|

|

|

|

|

|

|

|

|

||

|

Number of

atoms per molecule |

0.319683 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the

carbon metal ratio is |

21.45499 |

** |

|

|

|

|

|

|

|

|

||

|

|

|

or 21

carbon atoms to 1 metal atom |

|

|

|

|

|

|

|

|||

|

** If the

number were 22 there are no analogs that fit, if you carry out the

calculations further 21 is the closest number |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Emperical

Formula #3 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Another

way to view the results is to chose only the doped impurities of Fe ,Ni, Cr |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Percent

carbon |

|

75.80% |

|

The basic

ratio for the chemical structure for fullerenes with: |

|

|

||||||

|

Atomic Wt

of Carbon |

12.011 |

|

only iron

is |

14.56175 |

Or 15 |

|

|

|

|

|||

|

number of

atoms per molecule |

6.310882 |

|

structure

that would fit this molecule are: |

|

|

|

|

|||||

|

|

|

|

|

|

5XC6,6XC5 |

40XC6,0XC5 |

50XC6,48XC5 |

|

|

|||

|

%Metal

Element |

|

24.2 |

|

C60 |

|

C240 |

|

C540 |

|

|

|

|

|

Fe atomic

Wt |

|

55.847 |

|

4 Fe

atoms |

16 Fe

Atoms |

36 Fe

Atoms |

|

|

||||

|

number of

atoms per molecule |

0.433327 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Cr

corresponds to 14/1 and Ni corresponds to 15/1 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The following SEM-EDS dot maps further prove the proprietary

technology has encapsulated metal clusters to produce “Fullerene” magnetic

carbon that also have conductive properties.

“Fullerene Carbon Magnets”

The following SEM photomicrograph could only go down to 5

microns due to residual magnetism left during

processing indicating the magnetic carbon particles were magnetized

thus keeping the SEM electron beam

from focusing.

Note what appear to be huge fullerene “Bucky Ball” clusters

Tubular shaped rods and

other unknown objects

Strange rod like shaped objects were originally viewed as contamination such as lint or fibers from clothes and other surrounding potential sources. Additionally, they were too large in diameter to be carbon nano tubes (5 microns or .0002 inches) so not much was thought of these foreign objects. It was not until the EDS chart was studied showing the presents of the doping materials Fe, Cr and Ni that it was realized that the contamination was consistent with magnetic carbon components. The major difference was that that the doping materials for the tubular shapes were at a much lower level than Fe, Cr, and Ni in the magnetic carbon powder.

Magnetic Carbon Material Properties

Color –Black Solubility-Undetermined

Form –Amorphous, soot like Density- Estimate >or=1

Melting point-decompose or sublimes Conductivity- conductive

Special Properties- Ferro Magnetic (SEM- no Au coating needed)

Curie Temperature –undetermined Superconductivity-Undetermined

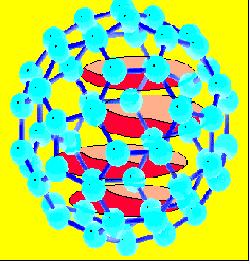

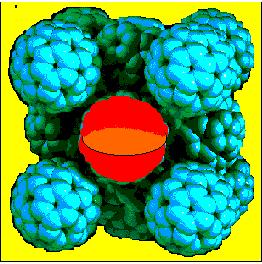

C60 Structure Encapsulation of Metal Cluster atoms

Figure

4 Figure 5

While

there are several conceivable models for encapsulation of the iron atoms, only

Figure 4 which

surrounds the iron cluster fits the analysis

ratio. In Figure 5 the ratio of Fullerene “Bucky ball” carbon atoms to iron

atoms is too high or if the Fullerenes were replaced with individual carbon

atoms, the carbon

to metal ratio is too low. (Blue color =C atoms, red color = Fe

atoms)

Immediate applications for Magnetic Carbon

Measurement of

small differences in low viscosity materials such as the differences in

viscosity of

MEK, methanol,

mineral spirits etc., is easily accomplished using settling rates of magnetic

carbon dispersed

in the solvent.

The application of a magnetic field is used to control the settling rates and

small differences in

viscosity can be

resolved.

Measurement of

polymer molecular weight differences is accomplished using the magnetic carbon

technology,

small differences

in molecular weight (the viscosity difference of solutions) can be resolved.

Coatings

applications: one example is using electrostatic spray systems to reduce over

spray, the same idea can

be applied using

magnetic carbon as a pigment and a magnetic field from a permanent or

electro magnet .

Further, powder

coatings uses the same technology and using magnet carbon as the prime pigment

will allow

(non colored)

coating to be directed to the part to be coated .

Dry toner for

xerographic copy machines, Xerox is said to hold numerous patents for such a

process.

Coatings

applications for hard drive memory storage, magnetic carbon will be easier to

disperse than iron oxide

or carbonyl iron

currently used for this purpose.

Present cost

of magnetic carbon

Presently the magnetic carbon is selling for $50 for 50 milligram plus shipping and handling.

Larger orders are available along with price break

reductions.

To place an order, call or email me for details and current

price at 216-381-3831, allisonpeterallison56@yahoo.com

( Note1, this is only one application of RW Industries

proprietary technology, there is an infinite number of materials that can be synthesized. If

you have specific material properties you are trying to achieve please write or

email us with your specifications)

(Note2, we are currently looking for

investors, venture capitalists, and in general funding for business expansion

purposes)