Project Work has Covered Many

Industrial Areas Such as Manufacturing, Research and Development, and

Marketing. Outsourcing and contract

work lowers overhead and saves time. Research

Work Industries has Much Experience to draw from in Solving New Problems.

Additional capabilities, include rapidly gathering new Information along with

“Hands On” Lab Application Work.

Recent Ink Jet Ink Project work

Ink Jet Ink physical properties are much different than ink or coating

from past processes that have traditionally been much higher in viscosity. Basically an ink or coating is formulated

with the application device in mind and ink jets are greatly different from

lithographic, offset, screen or any thing else used in the past for

printing. The closest device resembling

an ink jet is a paint spray gun and it has nothing to do with printing unless

you consider stenciling a form of printing.

Ink Jet printing is non-contact while previous printing methods have

surface contact with the substrate. See

example ink jet printed artwork using Spectra print

heads.

Ink Jet Ink Physical Properties

Viscosity- 5

to 15cps and most likely Newtonian in rheology

Surface Tension- 20 to 50 dynes/cm

Particle free- must not plug 10 to

40 micron ink jet nozzles

Pigment dispersions must be stable

and non-settling and

Not

agglomerate!!!

Ink

Jet Ink for continuous ink jet print heads must

have

a degree of conductivity.

Ink Jet Ink Drying Mechanisms

Absorption

Evaporation

Reactive

Polymerization

Phase Change

One of the most important physical

properties of ink jet ink is color.

Some useful color technology for

ink jet ink is as follows :

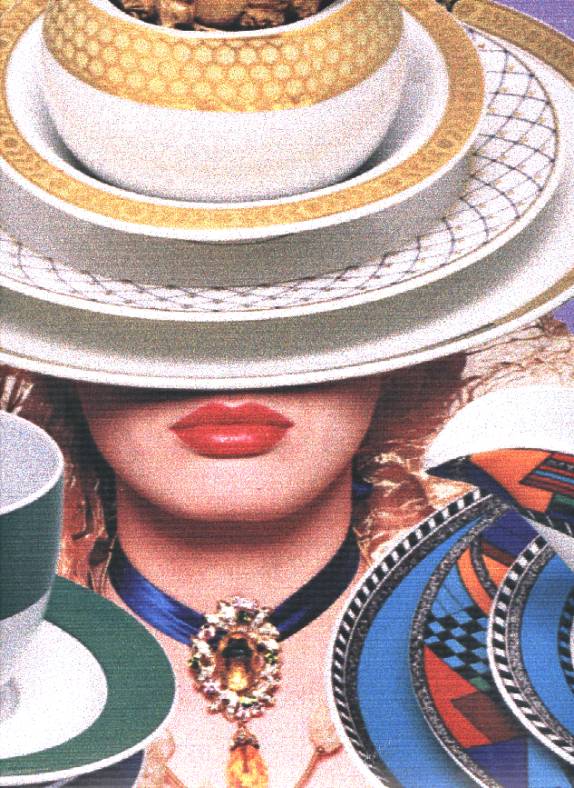

The following artwork is a portion of a wide format color ink jet printing on

flexible vinyl substrate(vutek ultraVu x300) and present to Research Work

Industries on a visit to Spectra’s research and development facilities in

February 2000.

This is a scan of the actual ink jet printing and gives some idea of the vast

potential of non contact digital printing and rich colors possible.