Builder’s Notes & Comments

Page 3

Back

to Airframe Log Index | Back

to Home Page

14 Sept. 03

Started

trimming up the ribs today. started by using a flush cutting router bit to trim

all of the excess gusset material, then used a scraper to scrape the excess

glue off, then sanded with my electric finish sander. Finished 12 of the ribs

today.

15 Sept. 03

Finished sanding

the last remaining 12 ribs. Jennifer

Johnson, one of my beautiful daughters helped guide each of the four spars

while I trimmed the excess “Flashing” off of the spars with my router which is

mounted up-side down on the building bench.

16 Sept. 03

I used the

alum. nose rib jig to mark all 16 on 1/4 ply and 8 on 1/4 plywood. Cut out the

patterns oversize so they can be routed to the proper shape. Also started to

make all the alum. root and spar fittings. 8 for the spars fittings & 8 for

the strut fittings. 2 for the aileron linkage.

17 Sept. 03

Cut out all 10

of the 1/4” nose ribs and 16 of the 1/8” nose ribs with the router. Marked and

cut out all of the spar strut attach doublers and glued them to the spars on

one side. Just need to drill the 1/2” holes with the forsner bit on the nose

ribs to have them all complete.

![]()

22 Sept. 03

Sanded all four

spars and filed the spar slots in all 24 Ribs.

23 Sept. 03

Trial fit all the

ribs on each of the wing spars. The ribs fit real well but the nose ribs need

to be trimmed a little on the bottom to fit tight. Re-shaped the alum. nose rib jig and

re-trimmed all 24 nose ribs . They fit nice and tight now with no over-hang on

the bottom.

24 Sept.03

Glued the spar

strut wing doublers on the other side of all four spars.

25 Sept. 03

Finished all of

the spar wing root and wing strut fittings by marking and drilling each of the

holes required. I made a tool to make the 1/2” radius on each fitting end by

using a 2x4 and drilling a 1/4” hole about a 1/2 inch from the end and sticking

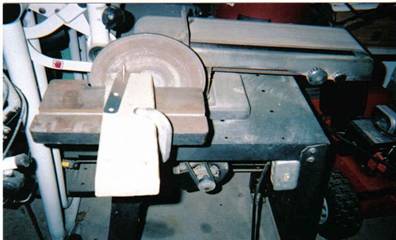

a 1/4” bolt through the hole, then clamping the devise to my big sanding

machine and moving the fitting from side to side.

26 Sept. 03

Made an aileron

end rib jig out of scrap 1/4” plywood. Marked each of the four aileron end ribs

on a/c grade 1/4” plywood and rough cut them out. Re-mounted my router upside

down in the building bench and trimmed all of the aileron end ribs with the

flush bearing router bit.

Made all of the

1/4” aileron nose ribs by using a 3-5/8” hole saw and cutting four holes, using

the piece from inside the hole saw and cutting the hole in half. This makes all

required 8 nose aileron nose ribs. four for each aileron. Sanded to make them

all symmetrical.

Made all of the

wing root fittings for the front and rear spars. Glued the front spar wing root

fitting doublers in place.

02 Oct. 03

Measure and

marked where all of the root and strut fittings go on all four spars and used

my drill press to drill all the holes accurately. The front and rear root

fitting spar ends are now ready to have the two root ribs notched to fit for

each wing.

03 Oct. 03

Notched all four

root ribs, two for each wing. They needed to be notched for each front and rear

spar. It was time consuming but went real well.

04Oct. 03

Sanded and

painted all 16 of the root and strut fittings with epoxy paint. I did this after receiving an e-mail from

Steve Kiblinger saying that the 2024T3 alum. is strong but is susceptible to

oxidation from the moisture in the wood which is almost undetectable because it

starts on the back side of the fitting.

He suggests that after painting to make sure the fittings are set in a

good bed of epoxy T-188 and then bolted with the 1/4” AN bolts.

10 Oct. 03

Sanded and

filed the gussets off of the aileron ribs so that the aileron spar will fit in

the proper place. Also had to remove one of the rib uprights on each of the

aileron ribs. I did this with a hand saw and file. Started to measure and cut

the diagonal pieces for each wing.

11 Oct. 03

Finished

cutting all of the diagonal and compression ribs pieces for each wing.

12 Oct. 03

Trial fit all the ribs on each wing front and

rear spar once again, and checked the fit of all compression rib pieces and

diagonal wing braces. They all fit nice and tight. Placed wax paper under all of the gluing surfaces

so the glue won’t stick to the work table. Glued and nailed all of the ribs to

the front and rear spar on both wings.

13 Oct. 03

Cleaned up all

the excess glue that seeped into the areas where the diagonals and compression

ribs go. I had to refit one of the diagonal pieces to get a tight fit, I’m not

sure why, the wing is still in alignment.

Glued all the

diagonal and compression part to the left wing. Took longer than I thought it

would.

18 Oct. 03

Sanded the left

wing glue joints on the diagonals in preparation for gluing additional fillets

to add extra strength. Glued the fillets in place.

Glued the

diagonal and compression rib pieces to the right wing.

Back

to Airframe Log Index | Back

to Home Page