Builder’s Notes & Comments

Page 4

Back

to Airframe Log Index | Back

to Home Page

19 Oct. 03

Glued the 1-1/4

“Sq. fillets to the lower side of each rib at the trailing edge in preparation

for gluing the trailing edge on to the wing.

20 Oct. 03

Glued both

trailing edges and top fillets on both wings. Also drilled the lightning holes

in all of the nose ribs with a 1/2” forsner bit. Looks good!!!!

26 Oct. 03

I am using

Jerry Eales (my E.A.A.) Tech Reps. idea for gluing the nose ribs to the front

spar. I cut and glued a piece of 1/4”

cap strip to the back side of each nose rib to make more of a gluing surface

which will be stronger than just butt gluing to the face of the spar.

27 Oct. 03

Glued and

nailed most of the nose ribs to each front spar. Also modified the two # 1 nose

ribs by added a tapered piece of 1/4 x 1, this was done because of the need to

notch out where the front spar root fittings are. This will give extra added

strength to these ribs. This idea came from Steve Kiblinger from California,

The guy who has the excellent web site on his building process of his Legal

Eagle.

27 Oct. 03

Glued the

remaining 6 nose ribs after notching out the # 1 nose ribs to fit the root

spars.

28 Oct. 03

Prepared the

front spar to glue the longeron to the nose ribs by marking the proper

alignment marks and adding wax paper to catch any unwanted glue drippings.

Glued both

longerons to each wing leading edge.

10 Dec. 03

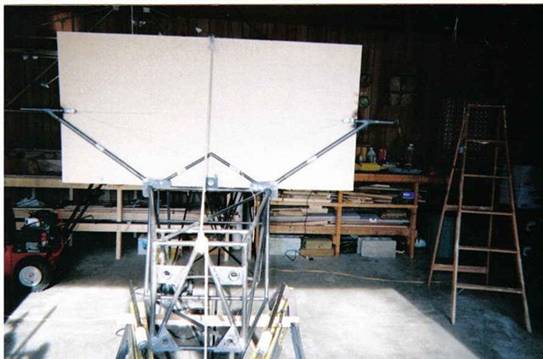

Made jig for

the landing gear today out of a sheet of 2 X 4 plywood 7/8” thick. I held it

vertical at the # 2 station where the gear / wing fittings attach with 1/4”

bolts and string.

I then drew out

all of the measurements on the front side of the jig. Cut the axle out of 5/8 X

.095 chrome molly and welded the attach plates that were laser cut from Dan

Ellerbusch cad drawings. Bolted the axle on to the jig and cut and fit both

gear legs that go from the # 2 station to the axle and tack welded them in

place. These were made from 3/4” X 049 which differs from the plans. It should

be much stronger than the original design.

11 Dec. 03

Measured , cut

and fit the rear strut legs that go from the axle to the # 3 station gear

fitting attach points and tack welded in place. Cut and fit the “X “ pieces out

with the use of my dremal tool after making a paper pattern. Cut and fit the

inside or lower pieces that make the shape of a W and tack welded in place.

15 Dec. 03

Measured and

cut the hardest part of the gear today, the spring strut assembly. I had the

help of Bauken Noack from the EAA restoration shop. He did most of the work

while I watched in amazement at the great work that is does. After he finished

the struts, I bolted them in place and welded the V plates in place.

01 Mar. 04

Made all of the

reinforcement patches that are used to strengthen the butt welds on the cock-pit

and wing attach tubes. These were made out of .035 chrome molly strips, heated

and tapped with a hammer to acquire the round shape needed for a snug fit when

welded to the tubes.