| Afterburners! |

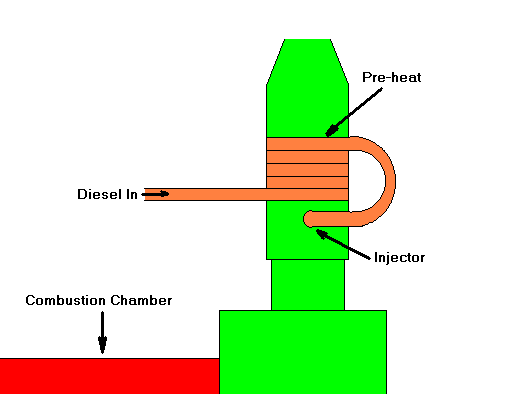

| Afterburners are a very simple devices to construct. All they do is inject raw fuel into the exhaust, and can produce up to 50% more thrust but at the cost of huge fuel consumption!. Here is a simple diagram of how to construct the afterburner: |

|

| The pre-heat is just plain old microbore copper tubing (10mm OD) wrapped around the exhaust. The purpose of this is to vaporise the diesel so it combusts easily. The injector can be as complicated as you want, but it can just be where the end of the copper tube is crimped almost shut. |

| Pressurising the fuel |

| The diesel needs to be pressurised before it enters the afterburner. This can be done by one of two ways: 1. Gas pressurisation of the fuel tank or 2. Pump. The pump system would be the easiest of the two to set up, but would lack the ability of rapid afterburner activation (very cool, makes loads of vapour and noise). The gas system is simple on paper, but is fairly difficult to set up in reality. All the gas pressurisation is, is an airtight fuel tank with a small inert gas <i.e. carbon dioxide or nitrogen> cylinder pressurising it. Then, the fuel can be delivered fast to the afterburner, so you can make lots of loud noise and vapour! The afterburner is controlled by varying the pump speed <in the case of the pump-pressurised system> or by a valve <in the case of the gas pressurised system>. I am going to go for a gas pressurised afterburner because I want to make lots of noise and smoke. |

| DISCLAIMER: The Author accepts no responsibility for death or injury as a result of turbo turbine construction. These devices spin at speeds of over 100,000 RPM and will have the same effect as a grenade if they destruct. I also accept no responsibility for partial or complete deafness as a result of improper hearing protection. THESE ENGINES ARE NOT TOYS AND MUST BE TREATED WITH RESPECT!!! |