This

is a chassis for those who want something simple without having to solder any

brass. I built this chassis in a hotel room at the beach during a rain storm.

Basically all you need for construction is sheet styrene (I use .040), a straight

edge, Xacto knife, and styrene glue. For glue, I use Testors model glue; the

liquid kind with the brush in the top. First, I put the body on the styrene

sheet and trace around it on the styrene with a pencil. Then I cut out the chassis

pan with an Xacto by scoring the lines and snapping the styrene.

The

next step is to cut the piece to hold the shaft end of the motor. Cut a piece

of styrene wider and taller than the motor. Using the Xacto point, rotate the

knife in the styrene to make the hole for the motor shaft. Keep testing the

hole until it is snug up to the motor. Then trim the piece flush with the bottom

and sides of the motor. Use this as the guide for the width of the two main

chassis ribs. I cut the ribs 3/4" wide and as long as I need for the chassis.

Then I cut the center braces and the side body mounts.

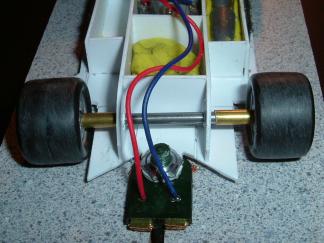

Using

the motor shaft as a guide, I mark the locations for the rear axle holes. The

axle holes are made in the same way as the motor shaft hole. Then I put the

axle through brass tubing pieces for alignment and put the tubing through the

styrene. I use two-part epoxy to glue the tubing to the styrene.

I

cut the hole for the guide flag and mount it to the chassis. After putting the

rear tires on the axle and the guide in the slot of the set up block, I can

measure the location for the front axle holes for the front wheels and tires

I am using. This chassis was going to be used for a Target modified coupe. I

used the wheels/tires that came with the toy for the front wheels. I took two

sets of the wheels and glued them back to back to get the wide look.

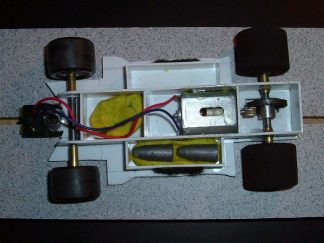

When

finished, the motor can be mounted to the chassis with hot glue or epoxy. This

car was set up for my oval track; therefore the weight is all on the left side.

For weights, no they are not ammo slugs. I use fishing weights in modeling clay.

The clay never hardens so it is easy to adjust the weight for different bodies/tracks.

The body is mounted with Velcro tape on the sides.

This

chassis runs very well on my routed oval. After testing it, I found that by

attaching a brass pan underneath the bottom with two-sided tape it handled even

better. When you get the hang of working with the styrene, you can crank one

of these out in about 30 minutes. It is a very cheap and easy way to build a

surprisingly durable slot car chassis.