|

|

|

| 2.0L ABA/JH engine that replaced the tired 1.7L, looks stock!

|

| After 22 years of use, the stock 1.7L engine was showing its age. The engine ran good, but was lacking power and

was leaking tons of oil. I decided that a ABA swap would be the easiest, because these motors are easy to find. I did

think about doing the 3A bubble block, but I had no luck in finding a good canidate. The good part is that a friend of mine

was selling a low milage early ABA block. It was in good shape and would be a great start to my new engine.

|

|

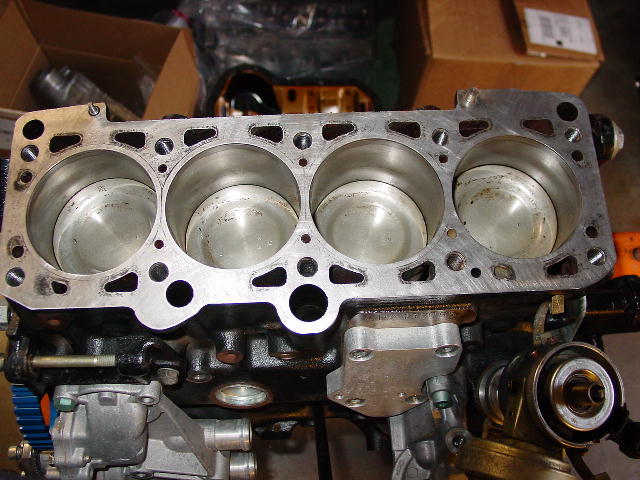

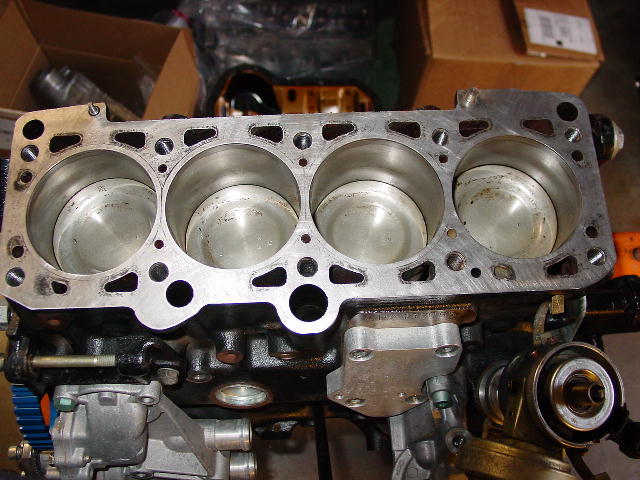

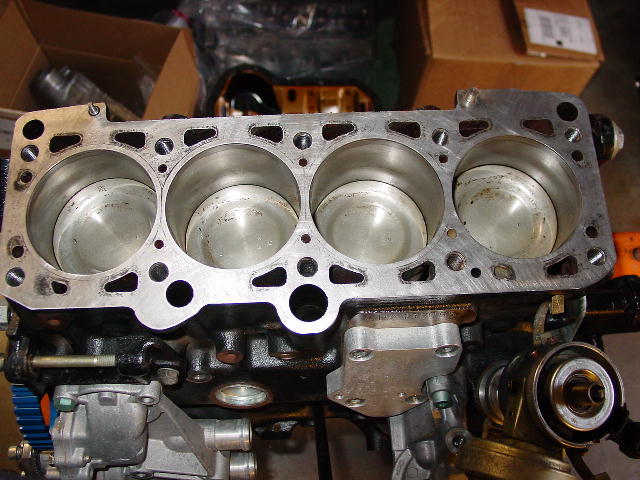

| I did not feel the need to rebuild the block since it only had 45K on it. The block came with everything for a A1 swap.

Techtonic WUR plate, distributor adapter ring and gear, A1 water pump, and a set of ARP head studs.

Just a little cleaning and it was ready to go.

|

|

| ARP head studs installed and a thin layer of copper permatex around the water and oil holes.

|

|

| Here is my 2.0 16V copper head gasket from SCE. With the stock headgasket the compression ratio would have been

10.3:1, a little too high. With California 91 octane and running without a knock sensor I wanted to bring it down a bit.

I found that SCE makes a .080" copper headgasket which would bring my compression down to 9.39:1 which I liked better. The

fit is good, but the locating pin hole was a little small. A quick trip to the drill press took care of that. It's important

to drill this hole good because it does locate the gasket to the head.

|

|

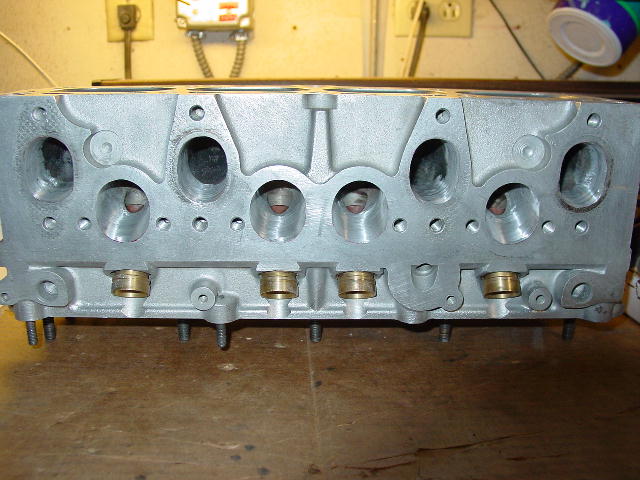

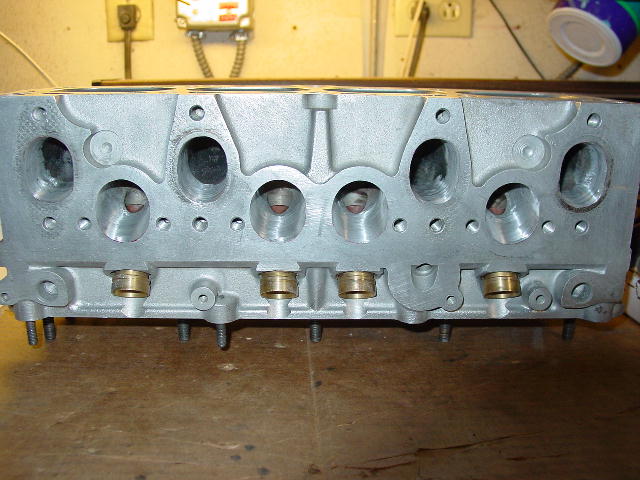

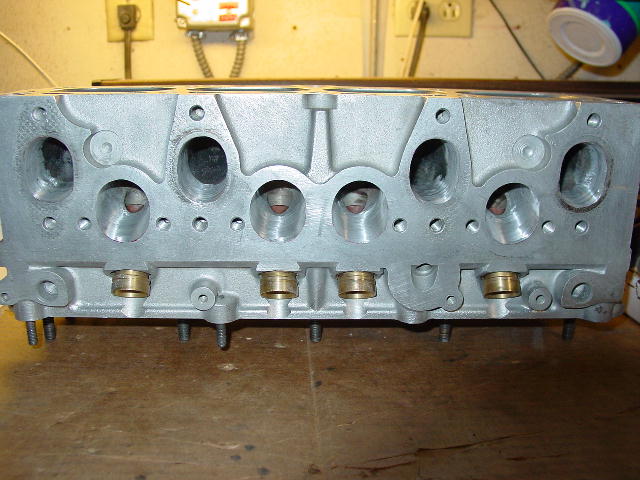

| Some of the port work done to the solid lifter JH head.

|

|

| Here is the JH solid lifter head bolted to the finished engine. The head has a 3 angle valve job, Techtonic sport

springs and adjustable cam gear, "G" grind cam, blended seats, and matched ported intake and exhaust ports. I tried not

to increase the port size to keep air speed good, just smooth out the casting.

|

|

| Another shot of the engine

|

|

| The ABA is 16mm taller than the 1.7L, so a little notching of the rain tray was needed. The swap also required a

taller down pipe from Techtonic p/n 251 211. Everything else including the upper stress bar fit without hitting anything. The use

of the upper stress bar did require dropping the throttle cable down on the valve cover. I just drilled a new hole lower and

cut a slit.

|

| Here is some info that might be useful for anyone wanting to work on a ABA swap. The deck height on the ABA is .024"

which is equal to 3.26cc's. I also cc'd the dish on the piston and it comes out to 14.6cc's. I also calculated the

headgasket volume for all of the SCE 2.0 16V copper headgaskets. The .032" = 4.5cc's, .043" = 6.04cc's, .050" = 7.03cc's,

.062 = 8.72cc's, .080 = 11.25cc's, .093 = 13.08cc's.

|

| Building a ABA with a stock deck height and a 30cc head will give you the following compression with these SCE gasket.

.032" = 10.47:1, .043" = 10.2:1, .050" = 10.03:1, .062" = 9.76:1, .080" = 9.39:1, .093" = 9.14:1. Summit racing carries

all of these headgaskets.

|

|

| This picture shows the AC compressor I installed. The unit is off a Toyota 4 runner. It went in easily, but

I needed to make a billet manifold and mounting bracket. This unit makes the car real nice to drive in the summer. System is

also running on R134A. The stock York pump was too heavy and did not pump well. I still need to finish the timing cover.

|

|

| New dual 8-3/8" fan from Flex-A-Lite, p/n FLX-365. Rated at 1600 cfm and weighs only 6 lbs. The stock

fan does look ugly compared to the new fan.

|

|

| Not only does it cool good, but it also cleans up the engine compartment. Takes about 15 minutes to install and fits

the Scirocco radiator perfect. Comes real close to the oil filter and AN lines, but does not touch.

|

|

| Custom manifold for the AC compressor that I machined. It uses all of the stock sensors and fittings.

|