Gamo CFX

The below operations are recommended to be made after the warranty of the gun

has expired and after the shooter is used to operating the gun, otherwise a

gunsmith can do it in a better and safer way. MODIFYING, REPAIRING, MISUSE AND

MISHANDLING THE GUN CAN CAUSE THE LOSS OF WARRANTY, SEVERE DAMAGE ON THE GUN

AND EXTREME INJURIES !!!

Here you can find the handbook and the construction of the CFX: handbook

, construction

CFX ADVANTAGES

1. on front of the gun can be mounted laser or flash light

2. the gun can be blocked by bonding the cocking lever with the barrel

3. after the pellet was loaded in the barrel you can leave a pellet in the breech, at the next arming the pellet is already in the breech and you must push into the barrel

THE CORRECT PELLET LOADING

The loading of the GAMO CFX is very important as the rotating breech allows few

mistakes that can be done during this operation, such as chipping the breech

seal because of the incomplete insertion o the pellet into the barrel. In order

to assure a correct insertion of the pellet, a soft material stick can be used

(eg. plastics, aluminium, copper, etc.) to push the pellet into the barrel. A

pellet inserteed too much will not have the entire power given by the gun,

because the ''trip'' along the barrel begins with an extra effort, as the

pellet's skirt is slightly bigger than the barrel and this contributes to more

pressure behind the pellet before it begins to move.

A RIGHT INSERTION OF THE PELLET IS DONE WHEN THE PELLET'S SKIRT IS AT THE SAME

LEVEL AS THE BARREL

TEXT:Cosmin-Ioan

PELLET LOADING WITHOUT ARMING THE GUN

We can load the pellet in the barrel without arming the CFX, with the pellet

already in the barrel we need only 1-3 seconds to charge and to shoot. When the

gun is not armed the breech is pressed to the barrel by the spring:

1) pull-back a little the cocking lever and rotate the breech

2) load the pellet

3) pull-back a little the cocking lever and rotate back the breech

THE REAR-SIGHT EXTRA-ADJUSTEMENT

One of the weak points of the CFX is the TruGlo open-sight, which is highly

sensitive and can be easily damaged by mishandling the gun. The rear sight can

have another problem: the elevation wheel can be loose because of the

inclination and the elevation adjustement will be modified by the shocks caused

by the gun firing, so after a few shots its accuracy will not be the same. The

elevation wheel must stop in its position as it has some fine radial grooves

beneath it. When the sight is too inclined, the elevation wheel is loose. This

can be fixed by adding a few strips of leather or rubber (as seen in the

picture) and by replacing the screw that holds the rear sight on the gun (you

can get to the screw by turning the elevation wheel until it comes off the

sight, be careful not to lose the spring), as the original one is quite short.

TEXT,PHOTO:Cosmin-Ioan

CHECKING THE FRONT BREECH SEAL

It is highly recommendable that this seal is checked from time to time, to

ensure its integrity, as it connects the rotating breech to the barrel.

This operation needs two people: one to hold the cocking lever at half of its

way and the other to operate the rotating breech. Before that you must extract

the breech's little plastic handle, paying attention to the small metal piece

that holds it in place inside the breech, as it can be easily lost. The cocking

lever is held in a position that allows the breech to rotate with little

effort, a small screwdriver is put in the handle's hole and the breech is

pushed towards the gun's rear until a small gap appears in front of it, after

this the same screwdriver can be used to push the breech even further along the

cylinder, until the front seal becomes visible and can be checked. After this

operation, the cocking lever is easily put in its place under the barrel, the

breech is coming along with it and the handle can be put back in its place.

TEXT,PHOTO:Cosmin-Ioan

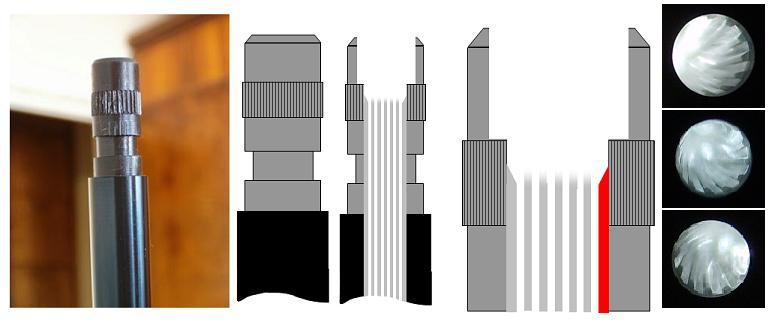

DISASSEMBLING THE GUN

The CFX is quite tricky at the beginning of this operation, as the front stock

screws are hidden under the rubber pads on the sides of the stock. Once they're

found, they can be easily removed. If this operation is done several times,

removing the pads and reassembling them with additonal short screws or to make

holes to get to the front stock screws would be proper solutions rather then

damaging them.

To disassemble the gun you need a special press (it can be easily home-made),

as the spring is already tensed inside the cylinder.

The gun has been disassembled after 3000 shots.

THE ROTATING BREECH has an area in which the crome layer has been peeled

off because of the pressure inside the cylinder and has marks of intense heat

along the hole that connects the cylinder to the barrel. The back-seal is very

fragile and it has been damaged.

THE PISTON has been modified in the factory as it had been made for a

larger cylinder (???) (the clear zone at its back end).

THE SPRING GUIDE is worn-off because of the friction with the spring

that was bent when I first disassembled the gun. The spacer is made of plastic,

an unfortunate choice.

TEXT,PHOTO:Cosmin-Ioan

Here are some more pictures, for explanations and better pictures you can

contact Cosmin