Current Developments

1. High pressure compressor for Wing’dmills

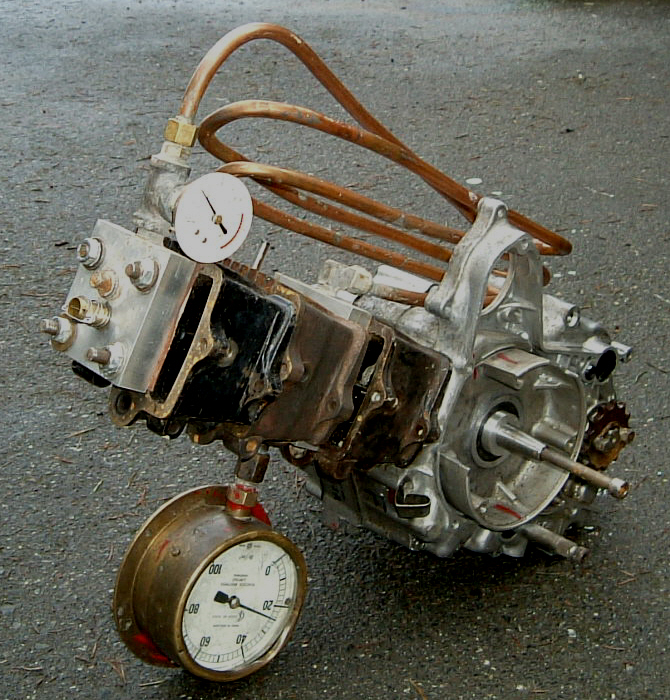

Testing a Yamaha 185cc motorcycle engine changed to a compressor head in 2001 and 2003 showed four areas needing development:

1) a robust ratcheting system

2) an internal form of torque smoothing

3) reduction of leaking for the wing’dmill’s intermittent operation

4) high pressure output for ease of storage and airtool use.

At the end of 2003 it was belatedly realised that as in the battery-charging work of the 1990’s, problems with the weakness of the available bicycle and car starter ratchets can be minimised by positioning them at the top of the gear stepup, and that there was indeed plenty of space available inside the oil-bathed engine for this at the clutch which wasn‘t being used anyways..

Then possible internal forms of piston counter springing to avoid the flailing and whipping of previous external springs were sought but frustrated by tight clearances around the connecting rod. The high pressure requirement suggested efficient intercooled two-stage double-acting compression and then that the smaller high pressure cylinder could be nested inside twin extension rods above the original cylinder and below an extension cylinder .

Happily these ideas all just matched with the only available engine at 50cc for the same work at higher pressure ( and it turns out 25% higher rpm and 25% less stroke truncation loss) than the Yamaha.

The Yamaha clutch was on the secondary gear but in the Honda 50cc, on the crankshaft for a big further reduction in ratchet torque. However it proved difficult to mount either bicycle pawl, or motorcycle or car roller ratchets, so that a pawl ratchet was made to engage the clutch components themselves at a very substantial diameter. This large diameter and low force and precision option had never been available with the tight constraints of racketing at the drive sprocket.

The standard motorcycle tierod cylinder and head mounting made it easy to extend the cylinder with the high pressure (HP) valve head, and then a cored block for the small diameter high pressure cylinder, then a normal block for the LP cylinder and finally the LP head.. The most difficult part was attaching the extension piston rods to the top of the original delicate aluminum piston. (sans oil rings).

The HP and LP pistons are interconnected by a central rod and used the standard cup seals proven with the Yamaha. However the cup dead space was filled with plastic plugs to minimise the knocking and jamming from minor bottoming out that plagued the setup of the Yamaha for the efiiceint minimum dead air space. This time the cam chain was rerouted to directly drive the engine oil pump and an oil path created to the high side of the top LP cylinder just under the cup lip BDC.

The previous experience was that standard compressor reed valves had to be adjusted most carefully to minimise high static leaking. Presumably they are demanded by the high rpms and temperature buildup of standard compressors. Here with intermittent operation at lower peak rpm and the certainty of good cooling in the wind, and finally the intercooling, the temperature should stay below 300F and the tolerance of high temperature if not standard O-ring seals. These were used on the seats of all 4 valves, 3 of which were sprung brass sliders in the solid aluminum heads with only the input HP valve remaining as a leaf because of space constraints.

The cylinders were separately bench tested and these valves developed to achieve very low static leaking. Nonetheless in the assembled unit the Intercooler loses static pressure to the engine space by leaking around the HP piston cup. To minimise this loss of air in intermittent operation the intercooler has to be optimised for high heat transfer but low internal volume and low flow friction using parallel connection of several fine bore copper tubes.

2) Updated Pullpump for the Flutterwell

The first Pullpump prototype on the Flutterwell was a successful testbed for the self-snifting capability. However the original pull pump configuration used custom seals handcrafted from plasticised PVC which were very exposed to abrading if not jamming with dirt on a less clean well, and could not retain the head over a calm night. The ultra-convenient foot pump PE rising main could not be obtained at the 4” size and semi rigid 20’ lengths with connections proved no easier than PVC, though a bit cheaper.

The current second prototype incorporates the latest pull pump configuration developed on the foot pumps with off-the-shelf seals well protected from dirt . The dedicated static seal has to be spring-loaded to maintain its static conformability despite potential contact every time the pendulum passes through center . Ordinary leather foot valves do not statically seal completely after all the hammering of pumping, and this leakback of head can represent a major inefficiency for windpumps with the intermittency of the wind. In all pull pumps, the ultimate hardstop will be the bottom of the plunger against the bottom cylinder bush.

Again to protect the static leather seal, the inner cylinder pipe has been changed from copper to PVC and for straightness and flow efficiency sdr 21 will be tried first.

Raingun 4” PE tubes are very thick wall to take the high spraying pressures and to avoid buckling in the powered tight winding. The biggest size of continous thin wall PE available is 3” which tightly accepts a short thin wall 3“ copper DWV insert whose middle is spun into a bulge that matches the PE in OD to ensure water column release when the piston leather is raised into it. Then with absolutely no pressure the cup should not deform to seal against the PE, provided the further withdrawal is slow enough. The transition piece’s lower end is expanded one wall thickness to give a soldering socket for a user bought standard 12’ DWV cylinder length. Thus the maximum stroke has been raised from 5’ to 6’. This system should allow one person to remove the entire pump into a high yield 4” deep well possibly even through the Flutterwell’s yaw bearing.

3) Updated and New Video Presentations of Footpumps, Wing’dmills, and sailboat