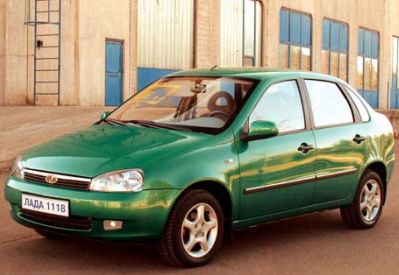

Lada Kalina Sedan 1118

De Kalina is in november 2004 in productie genomen en is in 2007 in Nederland geďntroduceerd. De fabriek beschikt over nieuwe spuitcabines, de kwaliteit en de kwaliteitscontrole zijn met sprongen vooruit gegaan, onder andere door de samenwerking met General Motors (van o.a. Opel, Deawoo, Hummer, Saab, Chevrolet, Pontiac...) en ook op motorisch gebied heeft Lada grote vooruitgang geboekt, onder andere door de brandstofinjectie van Bosch die nu in iedere Lada wordt toegepast. Lada stelt hoge eisen aan de toeleveranciers van onderdelen

De Lada 1118 is de sedanversie van de Kalina. Compacter dan de 2110, maar met een moderne modellijn. Verassend is de keuze van Lada om het Corsa-achtige Kalinamodel (1119) ook in stationcar en sedanversie uit te brengen. Hiermee wordt ook voor de mensen die niet meteen een grote bak willen aanschaffen de keuze voor een sedan aantrekkelijk. Groter dan bijvoorbeeld de 1119, maar je kunt hem wel kwijt in zowel de straten als de parkeerplaatsen van de drukke stad. Naast de moderne uitsraling van de buitenkant van de Kalina, is ook het interieur een enorme sprong vooruit op de 110-serie. Daarnaast is de Kalina met elektrische stuurbekrachtiging, airco en ABS, elektrisch verwarmde voorstoelen en op afstand ver/ontgrendelbare portieren ook qua comfort nčt een stapje voor op de 2110.Top

Lada 1118 8V

Vermogen: 59kW /80PK bij 5200rpm

Motorvolume: 1600cm3

Koppel: 120NM bij 2700t/min

Maximumsnelheid: 170km/u

Acceleratie: 0-100km/u in 12.9 sec

Verbruik: 6,2l/100km

Lengte: 4040mm

Breedte: 1670mm

Hoogte: 1500mm

Wielbasis: 2430/2410mm

Gewicht: 1080kg

Laadcapaciteit: 475kg

Inh. bagageruimte: 380 Liter

Top

Citroen-dealer: Twentelaan 21, 7609 RE ALMELO

Waarop moet u letten bij het kopen van een auto

1 Nederlandse autopapieren bestaan uit vijf delen, namelijk:

- Kentekenbewijs deel I;

- Kentekenbewijs deel II;

Roze: Geregistreerde eigenaar is een autobedrijf

Groen/geel: Geregistreerde eigenaar is een particulier

- Overschrijvingsbewijs - kopie deel III;

- Geldig APK-keuringsrapport;

- Set kentekenplaten (GAIK)

Controle autopapieren;

2 Vergelijk zorgvuldig het chassisnummer van de autopapieren met het voertuig.

3 Zelf rijden:

- Geldige APK noodzakelijk;

- Controleer het APK-rapport;

- Transitnummerplaten verplicht;

- Verzekering verplicht;

Controle APK-vervaldatum;

4 Vervoer op trailer:

- APK niet noodzakelijk;

5 Het is verboden met de Nederlandse (gele) nummerplaten op de openbare weg te rijden, als de auto is aangemeld voor exportTop

Autogas -ook wel automotive LPG (Liquified Petroleum Gas) genoemd- wordt in olieraffinaderijen geproduceerd. Hoewel autogas een bijproduct is van de winning van aardolie en aardgas en vrijkomt bij de raffinage van aardolie, moet het tegenwoordig aan strenge productspecificaties voldoen, om optimaal als brandstof in moderne auto's te kunnen worden gebruikt. Zoals de naam al aangeeft is autogas eigenlijk een gas. Om precies te zijn een mengsel van propaan en butaan. De mengverhouding varieert overigens afhankelijk van het seizoen een beetje. In de winter zit er meer propaan in autogas, omdat dit gas beter verdampt bij een lagere temperatuur. Het grotere aandeel van het goedkopere butaan in de zomer heeft tot gevolg, dat autogas in de zomermaanden zelfs nog iets goedkoper is dan in de winter.

Vulbegrenzer

Autogas wordt onder een druk van iets minder dan 8 bar vloeibaar gemaakt en op deze manier vervoerd en getankt. Omdat autogas uitzet als het wordt verwarmd, is vanaf 1984 een vulbegrenzer verplicht. Door die vulbegrenzer kan een gastank voor maximaal 80 % gevuld worden, waardoor het gas voldoende ruimte heeft om uit te zetten. Mocht de druk in de autogastank bijvoorbeeld als gevolg van een brand toch te hoog oplopen, treedt er een afblaasbeveiliging in werking, die de druk weer verlaagt.

Top

10-12-07

Lada maakt ongeveer 1 miljoen auto’s per jaar en heeft zo’n 70 procent van de Russische automarkt in handen.

Renault hoopt via Lada sneller te kunnen groeien in opkomende markten als Rusland en andere Oost-Europese landen. De Russische autoverkopen stegen afgelopen jaar met 20 procent. Renault is ook al eigenaar van het Roemeense Dacia en het Japanse Nissan.

Renault denkt straks in Rusland zo’n 100.000 eigen auto’s te kunnen verkopen. Renault betaalt naar verluidt ongeveer 900 miljoen euro voor een belang van 25 procent in Lada.

De Fransen delen straks de macht met het Russische staatsbedrijf dat nu Lada controleert. Beide krijgen de helft in handen van een houdstermaatschappij die ruim 50 procent heeft. Lada was in 2005 bijna failliet, waarna de Russische staat het bedrijf overnam. Ook Fiat en General Motors waren in de race voor Lada.Top

Honda addressed hybrid propulsion with the integrated motor assist (IMA) powerplant that debuted in its 2001 Insight hybrid electric vehicle. This two-seater uses a smaller-than-normal 1.0-liter, three-cylinder VTEC-E internal combustion engine that provides the power needed for most, but not all, everyday driving needs. On those occasions when heavy acceleration or climbing is needed, this hybrid turns to an ultra-thin, 10-kilowatt (13 horsepower) pancake-shaped electric motor located between the engine and transmission for supplemental boosts of power. Together, the two powerplants produce a combined 67 horsepower. Not a high-performance package, but one that confidently handles all driving needs.

Honda's follow-up hybrid, an iteration of its popular Civic, uses a larger 1.3-liter, 4-cylinder, dual port sequential ignition engine with two spark plugs per cylinder and the same supplemental electric motor. This IMA powerplant puts out a combined 110 horsepower to provide a very satisfying driving experience.

Toyota takes a different approach to hybrid propulsion. The Toyota Prius' hybrid system allows a driver to accelerate from a stop solely on electric power, generating absolutely zero emissions. Then, at a certain threshold, the 67 horsepower electric motor turns propulsion duties over to the vehicle's 76 horsepower, 1.5-liter four-cylinder internal combustion engine, which starts and takes over seamlessly. Both internal combustion and electric propulsion systems are used when driving demands warrant. The Prius' forward momentum is recycled into electrical energy through the car's motor-generator during braking and, like Honda's hybrids, this sedan's powerplant turns off completely when stopped to save energy.Top

As might be expected, powerful onboard computing makes all this happen. The power control system determines when the car is powered with electric power only (in the case of the Toyota Prius), internal combustion power only, at what point electric boost is needed, when the engine-generator should provide power to the electric motor and battery pack, and when the regenerative braking system should recycle kinetic power during braking and coasting to recharge the hybrid vehicle's nickel-metal-hydride batteries.

Other hybrid configurations are in development and production. A pure series hybrid uses an internal combustion or compression ignition engine-generator solely for providing electricity to a vehicle's drive motor, or motors. This type of powerplant has been used in diesel-electric locomotives for decades. A parallel hybrid allows a driver to select whether to drive via a car's traditional engine or an electric motor.

While generally not thought of in this way, the fuel cell vehicles now being field tested by various automakers are actually hybrids since they use an electrochemical engine (the fuel cell) and batteries to power electric motors. Other types of hybrids in development use energy generated during a vehicle's deceleration to compress air or hydraulic fluid in a high-pressure accumulator, then release this energy as a power assist while accelerating from a stop. Top

We will see other hybrid adaptations come to the fore, including the possibility of plug-in hybrids that allow driving a hybrid vehicle solely on electric power most of the time. This hybrid's internal combustion or compression ignition engine would only be used for more extended travel. Of course, such a configuration would require a much larger and heavier battery pack than the hybrids currently in showrooms and they could require lengthy recharging times, potentially presenting some of the same cost, packaging and operating challenges as the battery electric vehicles test marketed by some automakers in the late 1990s.

The energy needed to convert electricity to hydrogen energy is much more than needed to be converted to electricity from the grid to support plug in hybrid electric vehicles (PHEV).

Hybrids ? Japanese firms are planning for fullscale EV commercialization, with only intermediary sidestep for PHEVs perhaps. Ishitani pdf

Altair nano technologies has staked its future on 40-nanometer-size particles of lithium and titanium. It uses the particles to make a coating that covers a battery's anode, an aluminum bar that carries electricity to and from the vehicle's motor. By contrast, most hybrid cars, including Toyota's Prius, use a graphite coating, in conjunction with nickel metal hydride or lithium ion batteriesTop.

The difference is material: When a battery operates or recharges, ions pass through the coating of the anode. Graphite isn't very porous, so the ions literally deform the material as they force their way through.

This builds up stress and over time the graphite cracks, leading to high resistance and short life. Altair's nano-titanate coating, by contrast, has a large surface area. That means fewer ions try to force their way through at any given point, lowering resistance and minimizing damage.

By bypassing the graphite design, Altair also avoids dangerous overheating or thermal runaway that can plague large lithium ion batteries. Thermal runaway became a buzzword in 2006 when a Dell laptop computer spontaneously caught fire in a Japan office.

Nano-titanate battery lasts for 20,000 full recharge cycles. That's about 20 years, four times the life span of a comparable NIMH or lithium ion battery.

Altair started out as a materials research lab of mining giant BHP Billiton. In 1998, during a downturn in the mining industry, BHP sold the lab to Altair, at the time a shell company.

Tim Spitler, a former DuPont chemical engineer in that lab, spent the next four years learning how to use lithium-titanate to improve batteries. He and his colleagues devised a method to heat treat, mill and spray the material, which looks like a fine white powder, onto the bare aluminum anodes. That gave Altair a way to use lithium-titanate on a commercial scale. But the work didn't dovetail with plans by bigger companies, and the project was shelved.Top

When Gotscher joined Altair in 2004 he figured the company had a shot at making batteries fully in house. He raised $3.5 million in a secondary stock offering and hired a team engineers to build a working product. Last year Altair made 130 tons of raw lithium-titanate powder at the old BHP lab in Reno. It assembles 35-kilowatt batteries for the likes of Phoenix Motorcars at its factory in Anderson, Ind.

Then there's the challenge of where to get the big dose of power to recharge the batteries.

Phoenix recharges its electric truck battery in 10 minutes with a 440-volt charger, four times the amount of energy in a home wall socket. Scaling that operation, however, would be a challenge: Existing electric grids couldn't easily handle the power drain of rapidly recharging millions of such electric batteries.

So in early January Altair also built its first pair of industrial 1-megawatt batteries, each about the size of a freight car, designed to store excess electricity produced at night. The Virginia power utility AES plans to use the mega-batteries to warehouse power for use during peak consumption times.Top

Such batteries could help Altair offer 10-minute recharges to the masses. Futuristic filling stations might feature massive batteries below ground, replacing the gasoline storage tanks of today.

Without such infrastructure, going green will certainly take more time. Five-hour charges would be the fastest possible for residential drivers, admits Bryon Bliss of Phoenix motorcars.

AC Propulsion

AC Propulsion is a manufacturer of electric vehicles (EVs) and electric power systems for EVs and plug-in hybrid electric vehicles (PHEVs).

The first public demonstration of real-time vehicle-to-grid (V2G)

The vehicle, an AC Propulsion eBox EV, responded to the commands by charging or discharging its battery in short bursts that helped to balance supply and demand of power on the grid.Top

The eBox was receiving the same power commands as major power stations throughout the region, and it responded as they did only with smaller amounts of power. V2G has been demonstrated before, but never with actual real-time commands from the grid.

University of Delaware hosts research on technology, economics, and policy for V2G: V2G

MIDI Air Car

To maintain adequate pressure so that the main large cylinder is given a burst of pressure instead of a continuous slow push, a smaller cylinder is used to build pressure.

As the smaller piston collects the air and travels downward on its stroke the "articulated con-rod" lets this smaller piston rotate its rod on the crankshaft while allowing the main piston to be held at top dead center 70% of the time, until the smaller piston reaches the bottom of its stroke. Then the blast of air is delivered, driving the main piston down.Top

Located between the engine and the gear box, the moto-alternator produces brake power, starts the vehicle, provides extra power when needed and helps the CAT’s motor to allow the tanks to be refilled.

Over perslucht: CompAir

Hybrid cars

- A parallel hybrid uses both a gasoline engine and a set of batteries that supply power to an electric motor. The engine and the electric motor can turn the transmission at the same time, and the transmission then turns the wheels.

- A series hybrid uses its gasoline engine to turn a generator. The generator can either charge the batteries or power an electric motor that drives the transmission. In this model, the gasoline engine never directly powers the vehicle.

30-7-2008 Mening:

What killed the electric car is the lack of an on going cost. No radiator, no transmission, no oil changes, and no fuel filters. This is why you arent going to see any major car maker really pushing it. They make more on the maintenance than on the original sell.

PHEV are the next item car makers will make because it has the best of both worlds 2 engines (make consumers think they are being good little pleebs but still keep the ICE engine for the maintenance)

Lada Priora

Grond verplaatsers

Liebherr-site: Liebherr

Liebherr_wiki: Liebherr wiki_en

Caterpillar D11 Carrydozer D11 wiki_en

Komatsu D475 Komatsu D475 wiki_en