Batavus gebruikt in een model de zgn NuVinci-versnelling; een continu variabele versnelling gebaseerd op kogels ipv tandwielen.

IO Elektro Scooter

Der IO Elektro Scooter stellt ein optimales innerstädtisches Fortbewegungsmittel dar.

Seiner Reichweite ist 70 Km pro Ladevorgang.

Motor- und Antriebstechnik

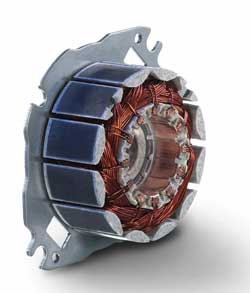

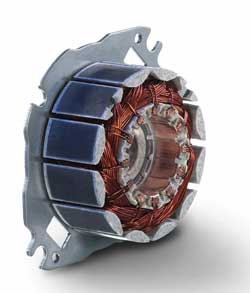

Bürstenloser Radnabenmotor in der Hinterachse integriert.

Getriebelose, verschleissfreie Kraftübertragung mit höchstem Wirkungsgrad.

Der Radnabenmotor erspart Kette, Getriebe dadurch mehr Platz, weniger Gewicht, keine Geräusche und geringere Servicekosten.

Fahrsicherheit

Mit Teleskopgabel, gelochter Scheibenbremse vorne sowie progressiven

Schraubenfedern hinten, ist der IO Scooter nach neuesten Sicherheitsstandards ausgestattet.

Für leichtes und komfortables Abstellen des Scooters sind ein Haupt- und ein Seitenständer serienmäßig vorhanden.

Eine leistungsstarke Lichtanlage für optimale Sicherheit auch Nachts, gehört natürlich zur Ausstattung des IO Scooters. Blinklichter vorne und hinten, Rücklicht und Bremslicht entsprechen den neuesten Standards.

Top

IO SCOOTER 1500GT 2007

Technische Daten

Länge/Breite/Höhe: 1700mm/880mm/1270mm

Leergewicht: 126 Kg

Zulässiges Gesamtgewicht: 266 Kg

Maximale Zuladung: 140 Kg

Maximale Geschwindigkeit: 45 Km/h

Motor: 2000 Watt Radnabenmotor

Reichweite: je nach Fahrweise bis zu 70 Km

Batterien: 4 x 12V 38 Ah Siliciumbatterien

Ladestrom/Zeit: 220V / 9Ah - 3 Std.

Bremsweg: 7 m aus 30 Km/h

Prijs: €1600,-

Rechargeable batteries used in electric vehicles include lead-acid ("flooded" and VRLA), NiCd, nickel metal hydride, lithium ion, Li-ion polymer, and, less commonly, zinc-air and molten salt batteries. The amount of electricity stored in batteries is measured in ampere hours or in coulombs, with the total energy often measured in watt hours.

PRAZE project

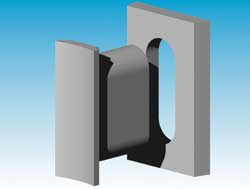

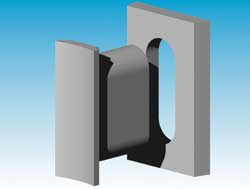

Design for low cost manufacture resulted in a motor design with only three mechanical cast/machined components. Earlier split-rim designs, where the tyre mounted directly on to the outside of the motor, which had a removable lip, were rejected in favour of a motor design that could be integrally attached to a standard wheel. This had the benefit of allowing the vehicle manufacturer to keep their standard wheel rims and enabling the motor to be designed with thinner components, as it no longer took the full strain and shocks applied to the outside of the wheel.

During the initial phase of PRAZE, two versions of motor drive systems were developed; the first prototype in-wheel scooter to be tested produced a maximum torque of 120Nm, exceeding the target of 100Nm. This presented some scope to reduce the size and weight of the motor. Subsequently a smaller motor was then specified, built, laboratory tested and fitted to another prototype vehicle. The rating of the smaller motor was increased further through improvements to the ventilation system. A detailed weight assessment revealed that even with a further iteration/ optimised design, considering all possible weight reduction possibilities; the existing topology of motor would not reach the required target for safe handling.

A comprehensive review into possible alternative motor topologies then concentrated on two main contenders, namely the brushless printed stator and the single tooth topology.

Both motor topologies were prototyped and tested, culminating in the single tooth topology being selected as the most suitable for taking into pre-production.

The main results of the PRAZE project can be summarized as follows:

- Four prototype demonstrator vehicles were developed, which exceeded the project performance requirements, with peak motor efficiencies of 82% @ 20Nm and 76% @ 80Nm (PML FlightLink)

- Mathematical models were derived to determine the maximum un-sprung weight for an electric scooter rear wheel. (Peugeot)

- Development of a Ni-Zn battery without any toxic components and a charge profile of less than 5 hours (Sorapec)

- The In-wheel motor drive system was advanced by the design of a lower weight, higher efficient, compact controller capable of operating over a battery voltage range from 24V to 72V (PML FlightLink)

- In-wheel motor weight was dramatically reduced with the innovative single tooth motor topology, culminating in an design for manufacture weight of 11.88Kg (PML FlightLink)

- An investigation report was compiled into Infrastructure and regulations, indicating that the PRAZE scooter will have a significant impact in our cities as a zero emission vehicle (Citelec)

Single tooth: Recent power electronics and control technology have equipped air conditioners with additional functions such as air purification and energy saving, however, the noise and vibration originating with the compressor still remains to be improved. The interior permanent magnet (IPM) motor has become the compressor drive motor of choice became of the need for small high-powered compressors. Due to the structural peculiarity of IPM, it generates not only magnetic torque, but also reluctance torque which helps to achieve high power density while aggravating the noise problem. In this study the influences of natural frequencies and mode shapes of the structures were investigated to reduce the noise and vibration of an IPM motor.

Direct-drive brushless direct current (DC) motor specifically for this scooter, which peaks at 20 kilowatts with currents up to 300 amperes and 65 Newton meters (Nm) of torque to provide exceptional acceleration of zero to 50 kilometers per hour (km/h)in 3.6 seconds. The motor configuration is optimized for space constraints, while the motor is optimized for cruising and high acceleration. The motor also features a high pole-count design for maximum torque per watt, an innovative single-tooth segment winding for higher reliability, automated assembly and lower cost.

Soft magnetic composites (SMC),e.g. Somaloy

single tooth topology

single tooth armature

single tooth wound armature

Iron powder based soft magnetic composites (SMC) shows high geometrical design flexibility thanks to their fully isotropic magnetic properties.

The diameter of the individual particles in SMC’s are typically in the range of 50 - 250 µm.

The resistivity of SMC materials is created by e.g. polymer binders but also, and much more efficiently, by inorganic coating of the individual powder particles like the Somaloy® materials. The resistivity can then be increased to significantly higher levels compared to e.g. silicon-alloyed solids.

SMC-materials, like the Somaloy® products (Höganäs AB), are isotropic 3-D core materials with relative permeability in the range of 400 to 700 which in general is lower compared to laminas as shown in Fig.2. The isotropic 3-D resistivity is typically in the range of 40 to 1000 µ?m. Components of SMC are efficiently manufactured by net-shape die-compaction followed by heat-treatment to achieve optimal magnetic performance.

56 9-4-2009

www.spartamet.org/

Sparta maakt deel uit van de Accell Group, een internationale groep van ondernemingen in ontwerp, ontwikkeling, productie, marketing en verkoop van fietsen, fietsonderdelen en -accessoires.

www.accellgroup.nl

Binnen Accell is er een Ebike Competence Centre (12 medewerkers) dat elektrische componenten ontwikkeld: software, hardware en mechanica.

Steef Niesing: s.niesing@sparta.nl

Raleigh.co.uk/

Electrische motorfietsen

The breakthrough for electric vehicles was the lithium ion cells for power tools that reached the market in 2004. One expects a real boom once energy density increases from today's 120-watt hours per kg to 500-watt or 600-watt hours, which is the same performance delivered by gasoline. At that point there will be a switch. There will be more electrical vehicles than gas vehicles.