|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine |

|

|

|

|

|

|

|

This isn't a very good pic but I'll explain what is here. This is under the left rear fender. In the center is the custom heater box. The tube towards the camera is the incoming air from the fan mounted in the passenger compartment. Just in front of the filter it enters the heater box and the rest of the air flow is stock. The original intake for the heater box was cut and welded shut. Look for that on another pic. The full flow system is Gene Berg. Just above the muffler is a braided SS line to the filter. From the filter the oil goes to a Perma Cool thermostat controlled bypass valve. Under I think 180 degrees the oil does a normal loop. Over that temp, the valve opens and the oil runs through a Kymco super cooler with a fan that will kick on if the oil ever gets over 210 degrees. I just wanted to have it covered. |

|

|

|

|

|

Here's another shot of the same area. As you can see, I have adjustable spring plates, Bilstein shocks, and I have left my parking brake on a couple of times as I drove. The drums used to look perfect until I drove a few miles with the parking brake slightly on. Oh well. Just inside the shock, the cooler is bolted over the tranny. The decklid release cable fits nicely in the fold just above where the oil cooler hoses run. The valve cover is hard to see because its black. The reason it is stock is because stock ones have the best fit. Also, always use the stock cover bail springs. They are made of spring steel where as the cool aftermarket crome ones are just soft steel. Hello leakage. VW had a couple thing right and that is one of them so keep all valve cover stuff stock. |

|

|

|

|

|

|

|

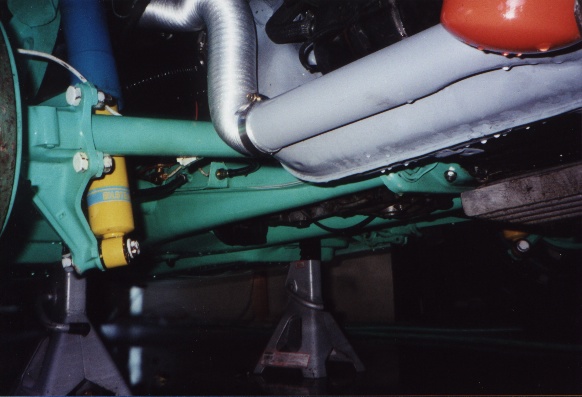

The whole pan is painted a pastel mint green color. The pan was first sandblasted, then a coat of etching primer, then a coat of filling primer, and finally the paint. It has lasted very well over the years to my surprise. Only problem areas have been created by me. For example, brake fluid is very corrosive and I damaged a lot of piant with it. Also, areas that should have had seals, allowed water to collect in the drivers footwell structural areas that created some rust between welded areas. Not alot, but not perfect. This shot also shows the Berg sump. |

|

|

|

|

|

|

|

|

|

A not very interesting shot of my engine compartment. There is an aluminum firewall cover, breather system and dual Kadrons. I am not exactly sure why I painted the inside of the decklid green and I often question my decision but its done. You can see the welds where the license light was filled. Also the male part of the '68 front hood latch can be seen here were it is welded on the decklid. The latch itself is opened by remote. A cable runs from the latch to the side of my seat. A mountain bike shift lever is attached to the seat frame and acctuates the whole thing. I case anyone else here wants to do this, the cable is a tandem bike shifter cable available at most bike shops. You then purchase the same amount of housing and your done. It was surprisingly simple. |

|

|

|

Picture to come |

|

|

|

|

|

|

|