Articles \ "A Model American Watch Factory"

Click on the thumbnails to view the larger image.

THE WATERBURY October, 1893

A Model American Watch Factory

A jeweler is naturally interested in the appearance and operations of a high class watch factory. And no doubt many retail jewelers all over this country, will add their general interest in the subject a special gratification in the prosperity and active enterprise of a factory which has established such cordial business relations with the trade as those existing between the Waterbury Watch Company and their customers. They certainly will take pleasure in looking with their own eyes, so to say, into the home of the Quick-Winding Waterbury.

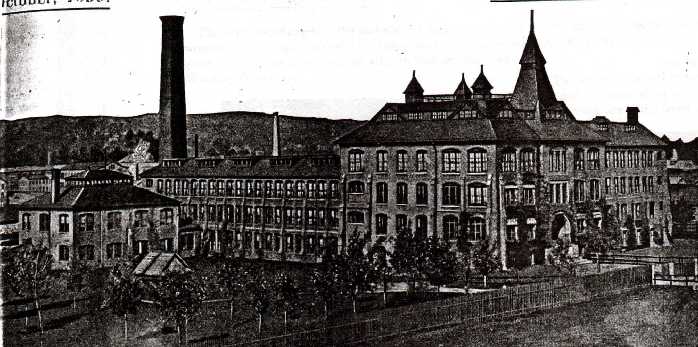

The factory is one of the finest in the country, using the most modern automatic machinery, and employing a high class of skilled operatives. From an architectural point of view the building is remarkably beautiful. It is covered in front and at the sides by a fine growth of Ampelopsis Vetchi; and spacious lawns, answering the practical purpose of avoiding annoyance and trouble from dust, set the building off to advantage.

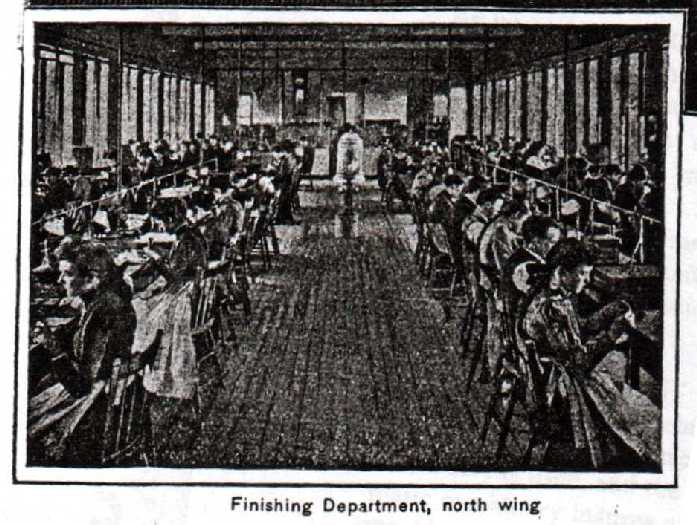

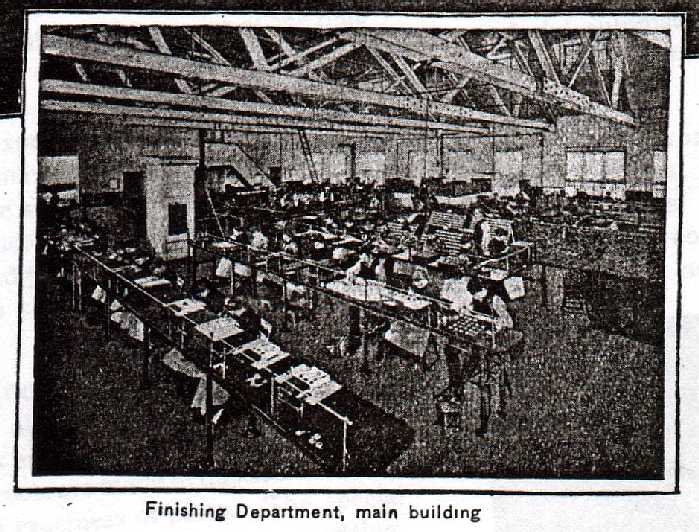

Finishing Department

The Finishing Department occupies all the third or upper floor of the factory. The ceilings and lofty walls are painted white, and the numerous windows afford the maximum of light and ventilation. In this room the watches are assembled, run and regulated in a systematic manner. No watch is allowed to pass from this room until a final inspection shows that it is all right in every aspect.

Gilding Room {not illustrated}

Into this department the parts when finished in the case and train departments are brought and thoroughly cleansed, and such parts as would be likely to tarnish are gold plated. The cases here receive their finishing, damaskeening and final polish, and are ready then for the wearer.

The changes wrought in the looks of the various parts are wonderful – dirt and grease are vanquished, and a gloss given which is the admiration of all who look on the Quick-Winding Waterbury.

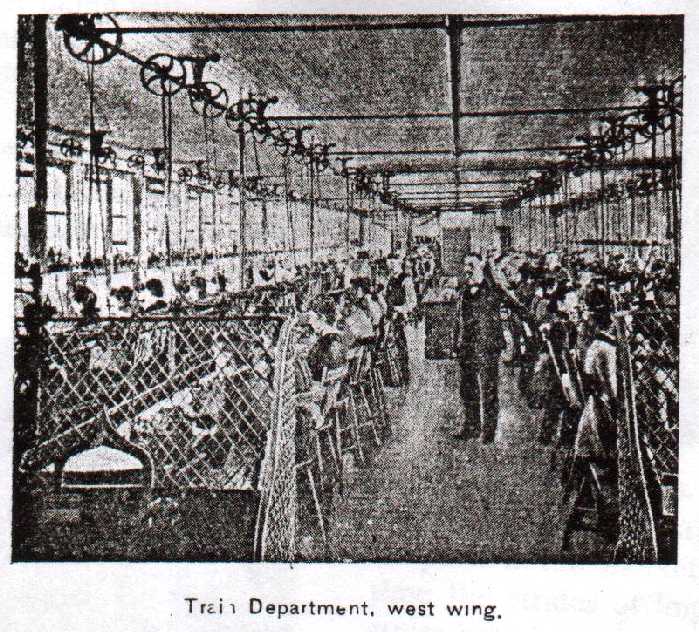

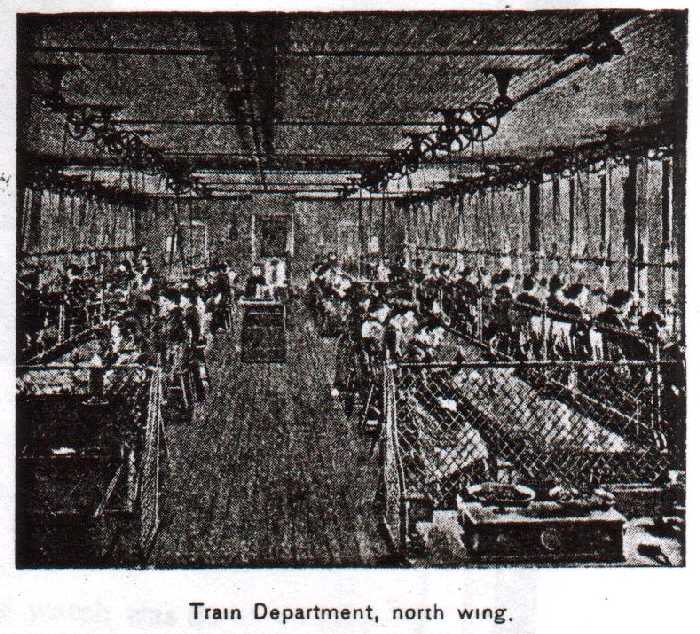

Train Department (west and north wings.)

As its name indicates, the train or movement of the nine or ten series of watches now on the market, is made in this room. Much of the machinery and many of the tools are the outgrowth of ideas and experience, and are the work of the company’s own mechanics. Operations are many, varied and interesting. Some small parts, like the balance staff, require more than a score of operations before they are completed. The staff and pinion turning, polishing and wheel cutting are operations similar to those performed in other watch factories.

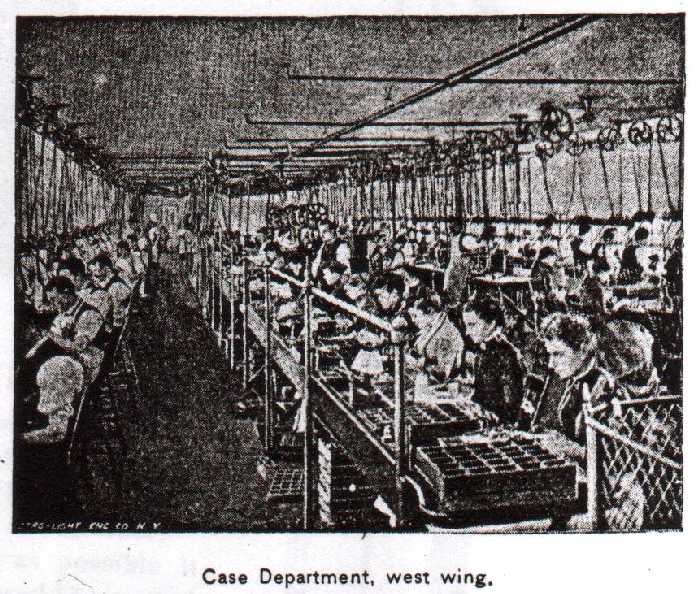

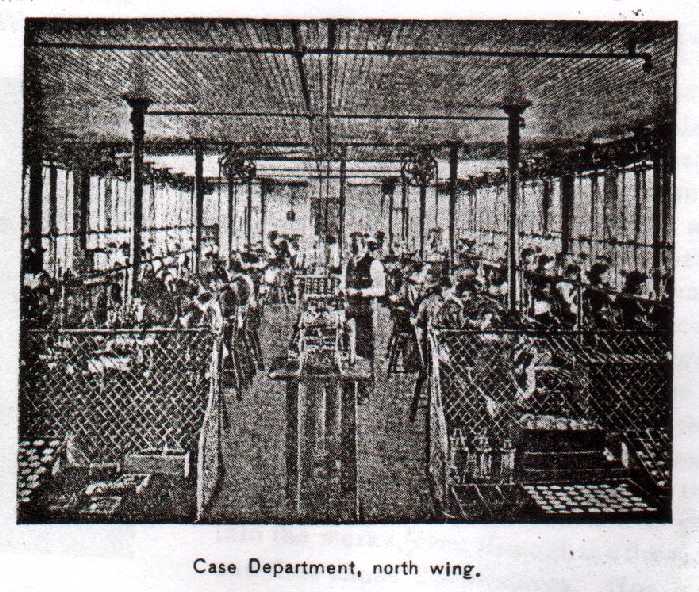

Case Department (north and west wings.)

In the Case Department all the Silver, Nickle and Gold open-faced and Chatelaine cases are made. None but the best of machinery is used, and the tools are made in duplicate. Automatic machinery insures an exactness of parts. The special machinery for engraving and engine turning, jewel setting, and for the heavy work necessary on the plates, presents many mechanically novel ideas. The Bassine case made by this Company is as fine a specimen of case making as can be shown by any case makers.

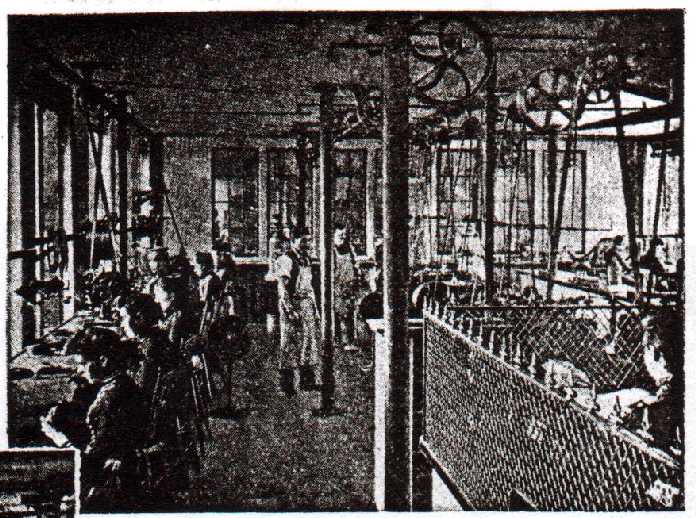

Machine Shop.

The machine shop is thoroughly equipped in every particular, and the tools, all of which are the production of our own machinists, are of the finest class of workmanship. Many of the wonderful automatic machines, in use throughout the factory, are also of our own make.

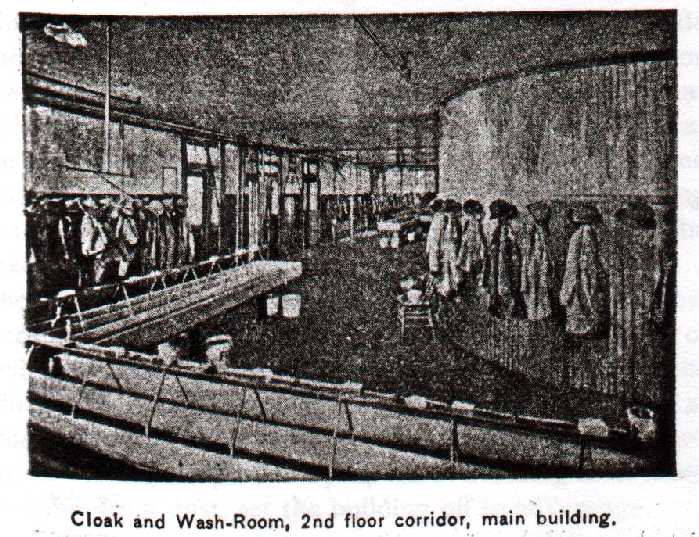

Corridors

Corridors opening from the large front halls into the wings are used as wardrobes. Each employee has a hook designated by a name plate. Large sinks with an abundance of fresh water and soap conserve to cleanliness. Each sink is thoroughly cleansed and filled with fresh water twice daily.

Spring Department.

In the spring department is manufactured the power which makes the “wheels go around.” Machinery in use is all of original design, and very interesting in its operation. Not only the surface but edges of the springs are polished, as well as drawn to secure exactness in thickness. Steel from 6 ½" - 1000" upward is used, and the springs used in the Wuick-Winding Waterbury are superior to all others in quality and temper.

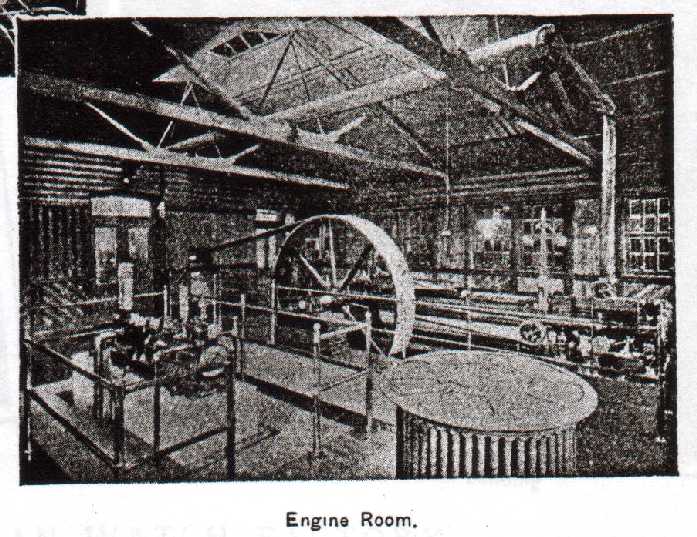

Engine Room

The engine room is a beautiful room finished in natural woods – open timbered roof. Seventy-five horse-power Rollins engine and hot water pump with gauge board and gauges, polished brass railings around exposed places, and polished floor make this the “parlor of the factory.”

The manufacture of Waterbury watches was commenced in a small room of the Benedict and Burnham Manufacturing Company. Success being demonstrated, a new factory was built, this being later enlarged to accommodate the increasing business. On March 3rd, 1880, the plant was purchased from the Benedict and Burnham Manufacturing Company, and The Waterbury Watch Company was organized, with a capital stock of $400,000.

The first Waterbury watches were put on the market right before the holidays of 1879. Previous to this time there was nothing between the cheap toy watch at $10, and the poor Swiss watch selling at $15. It remained for the Waterbury Watch Company to commence within the reach of masses the only luxury they lacked to make them equal in possession to their wealthiest companions – a watch. The Waterbury watch was from the start a success. It at once took its place in the market as a favorite, and since that time the strides of improvement in the models and styles have been rapid and continuous.

The manufacture of the long-wind watch was discontinued several years ago. Now it is the improved Quick-Winding Waterbury, made in many different sizes and styles, with nickel silver and gold cases.