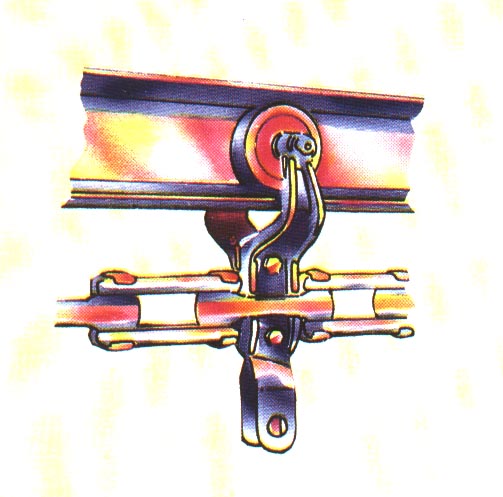

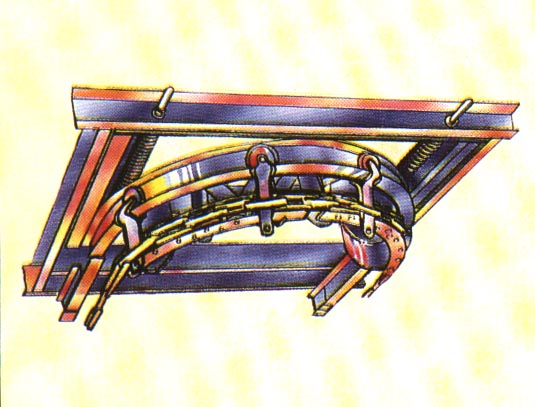

| The unique adaptability of continuous overhead conveyor systems makes it one of the most useful material conveyances. Overhead conveyors can be made to turn in any direction, go up or down from level to level, or even run vertically. Utilizing otherwise unused space overhead, it can go where workman cannot: through intense head or cold, through acids, through spray and dip painting operations, through complicated production methods. Custom engineered accessories allow the overhead conveyors to carry any kind of load safely, economically and at the rate of speed desired. All overhead chain conveyor installations are custom engineered to meet the requirements of the customer, yet, most component parts are "off-the-shelf" items, allowing faster delivery and reduction in costs. "X" TYPE CONVEYOR The simplest and most effective conveyor chain yet devised. Assembled or disassembled without the use of tools, the X type chain contains no rivets, welds or bolts and requires no special joining links yet may be disconnected at any point. It is accepted as a conveyor world standard because: All parts are drop forged from high carbon steel and heat treated for maximum strength and wear resistance. Trolleys may be assembled on practically any desired centre without the use of special attachments on the chain. Its STIFFNESS has been increased in all transverse directions without increase in weight. Its RIBBING and WEB provide much larger contact area. Its BI-PLANER FLEXIBILITY enables a steeper vertical bend to be used. It can be used "on edge" or "on flat" with equal efficiency. Available in 3 sizes from medium size loads to heavy duty industrial use: X348 - 11000kg U.T.S X458 - 22000kg U.T.S X678 - 38500kg U.T.S "X" Type Chain and Red Seal Trolley "RED SEAL" TROLLEYS Precision engineered - the smoothest moving Trolley yet built - lowest possible friction factor - sealed to keep lubrication in and dirt out. Principal features of the design: TRIPLE LABYRINTH SEAL: Three walls of steel to keep the lubricant in and contamination out. HARDENED STEL WHEELS: Contoured to fit the flange of the I-beam on which they ride. LARGE ALLOY STEEL BALLS: Highest quality alloy steel balls operate in deep groove retainer type bearings, the wheel life is greatly extended. PRECISION GROUND RACES: Large diameter. Ground to precision specifications - less friction. WELSH PLUG: The bearing seal, or Welsh plug, fits snugly into a machined groove in the trolley wheel. It protects the bearing from injurious foreign matter, but it is easily removable if desired. STURDY DROP-FORGED BRACKET: The wheel is firmly swaged to the bracket, eliminating loose rivets or bolts, making the wheel and bracket an integral unit. PRESSURE TYPE GREASE FITTINGS: The heavy shrouded bracket head protects the grease fitting from damage. Rugged two-bolt connection, double staked to eliminate the possibility of the trolley coming loose in service. DRIVE UNITS Two standard types of drives (Caterpillar and Sprocket) are available for overhead chain conveyor systems. A caterpillar drive uses a chain made of precision steel rollers with driving dogs that mesh with the links of the conveyor chain to deliver the driving force. A sprocket drive makes use of a sprocket whose teeth mesh with the links of the conveyor chain to deliver the driving force. Floating Frame Caterpillar Drive TAKE-UPS There are two basic types of take-ups - Traction Wheel and Roller Turn. Both units are made in several styles. The most common styles are available on request. Because the spring type take-up is automatic and requires very little maintenance, it is the most popular. The screw type must be manually adjusted and requires more maintenance. Take-ups have a dual purpose: keeping the conveyor chain tight and permitting the removal of excess chain. Take-ups should be located after the drive unit, and if possible, at a low level in the conveyor. Roller Turn Take-Up HORIZONTAL TURNS On horizontal turns, either a traction wheel or a roller turn assembly must be used to hold the conveyor chain under the vertical centreline of the I-beam. TRACTION WHEELS: This most efficient type of turn reduces chain wear and has one point lubrication for easy maintenance. Because the chain rides the wheel around, there is less friction, reduced chain pull, and longer chain life. When a conveyor must operated in dust laden atmosphere, corrosive fumes, heavy moisture or excessive heat, a traction wheel is generally the most desirable horizontal turn assembly. Available with tapered roller bearings or carbon bushed bearings for high temperature applications. ROLLER TURNS: Roller turns are economical and when properly lubricated will operate in temperatures up to 120deg C. Rollers are fitted with heavy duty grease packed sealed for life ball bearings. Electrostatic paint spray loops and any type or size of special roller turn can be furnished. Traction Wheel Assembly |

| 170 Beaconsfield Street, Milperra NSW 2214 Australia Phone: 61 (2) 9792 4414 Fax: 61 (2) 9792 4940 |

|

|

|

|

|

| Conveyors |

|