MEC-T3-2

Tuesday

12:45 - 2:15 PM

Philadelphia PA

15 September 1998

Owen Wengerd

ManuSoft

Fredericksburg, Ohio

PO Box 84 OH 44627

www.manusoft.com

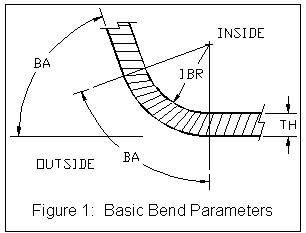

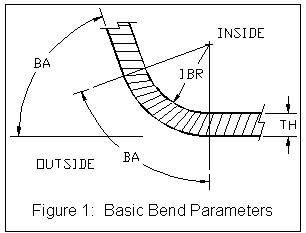

*Note BA (Bend Angle), TH (Thickness) and k (eg 0.4 for mild steel) are data. All the rest are calculated.

| BA | Bend Angle (in degrees) | NBAR | Neutral Bend Arc Radius |

| DBL | Developed Bend Length | OBA | Outside Bend Allowance |

| IBA | Inside Bend Allowance | OBLO | Outside Bend Line Offset |

| IBLO | Inside Bend Line Offset | OBR | Outside Bend Radius |

| ITI | Inside Theoretical Intersection | OTI | Outside Theoretical Intersection |

| k | k-factor (usually 0.4 for mild steel) | TH | Metal Thickness |

Additional Definitions

IBR Inside Bend Radius (often just BR) and is where the "punch part of the brake tool fits.

(The outside is in contact with the die when the sheetmetal is being broken (ie bent).

pi 180 deg expressed in radians (pi=3.4159 to 4 decimal places).

DBL Developed Bend Length is the arc length of the neutral axis ie "length=br+(k*th)*ba" (cf s=rA).

(Note: A rule of thumb for low carbon steel "material offset" or "k-factor" is .33 for bends less than material thickness (t), .40 for bends t to 2-3t, and .5 for bends greater than 3t or rolling. Multiply

by Pi/2 to convert to Pro E's own &qu0t;Y-factor&qu0t;. I've had success with Aluminum using the same numbers. -aj)

| QTY | ANY ANGLE BEND | 90° BEND | |

| NBAR | = k * TH + IBR | = k * TH + IBR | |

| DBL | = NBAR * BA * pi/180 | = NBAR * pi/2 | |

| = (k * TH + IBR) * BA * pi/180 | = (k * TH + IBR) * pi/2 | ||

| IBLO | = IBR * tan(BA/2) | = IBR | |

| OBLO | = OBR * tan(BA/2) | = OBR | |

| IBA | = DBL - (2 * IBLO) | = DBL - (2 * IBR) | |

| = (k * TH + IBR) * BA * pi/180 - (2 * IBLO) | = (k * TH + IBR) * BA * pi/2 - (2 * IBR) | ||

| OBA | = DBL - (2 * OBLO) | = DBL - (2 * OBR) | |

| = (k * TH + IBR) * BA * pi/180 - (2 * OBLO) | = (k * TH + IBR) * BA * pi/180 - (2 * OBR) |

Steps To Develop A Bend

1. Calculate the NBAR.

2. Calculate one of:

a) IBA if mostly inside dimensions are known

b) OBA if mostly outside dimensions are known

c) DBL if mostly dimensions to tangents are known

3. If any dimensions need to be calculated, do so.

4. Total all the dimensions, then add the associated bend allowance(s) (IBA, OBA, or DBL).