Project Leader

Postdoctoral Researcher

yancy_riddle@yahoo.com

Diploma student

(dr.ing. student starting 6/2002)

hakoh@stud.ntnu.no

Institute Leader

nils.ryum@chembio.ntnu.no

|

|

|

| Yancy W.

Riddle, Ph.D.

Project Leader Postdoctoral Researcher yancy_riddle@yahoo.com |

Håkon

Hallem

Diploma student (dr.ing. student starting 6/2002) hakoh@stud.ntnu.no |

Nils Ryum,

prof. dr. techn.

Institute Leader nils.ryum@chembio.ntnu.no |

| Location:

Institute for Materials Technology and Electrochemistry Norwegian University of Science and Technology (NTNU) Alfred Getzvei 2b N-7491 Trondheim, Norway |

Relevant references &

resources:

Sc related resources |

Research Area: Study of Recrystallization in Aluminium Alloys

Current Research Topic: Addition

of Sc and Zr to Aluminium Alloys: Improving Recrystallization Resistance

Introduction:

Preventing recrystallization

in wrought aluminium alloys may result in the retention of strength, hardness,

corrosion resistance, fracture toughness, as well as decrease weld cracking.

These properties and more are often vital for the success of an aluminum

alloy in a given application. For the same reasons the alloy may

be required to survive long elevated temperature conditions in-service

and retain an unrecrystallized state. However careful control of

alloy composition and material processing conditions are needed if

these conditions are to be met. In particular the various processing

temperatures, processing times, and severity of deformation all contribute

to the challenge of recrystallization prevention.

In this research we employ various dispersoid phases to pin grain and subgrain boundaries thus preventing recrystallization. This is termed "Zener drag". The effectiveness of dispersoids varys with composition, size, volume fraction, distribution, and degree of coherency to the matrix. To date Al(3)Zr is the most effective dispersoids in use in aluminium alloys. Unfortunately Al(3)Zr is often difficult to precipitate resulting in strongly heterogeneous distributions having a less than optimal ability to retard recrystallization.

Recent research has shown scandium, when precipitated as Al(3)Sc, to be a particularly effective Zener drag agent. Ease of nucleation, high volume fraction, and homogeneous distribution contribute to its effectiveness. Furthermore scandium heat treatment is compatible with current practices making it an attractive addition to aluminium. However Al(3)Sc coarsens much faster than Al(3)Zr reducing its usefulness over longer high temperature annealing times. It has been discovered that combining Zr and Sc in the same alloy can, with proper heat treatment, result in an Al(3)(Sc, Zr) dispersoid which takes advantage of the positive properties of Al(3)Zr and Al(3)Sc. Al(3)(Sc, Zr) nucleates rapidly and homogeneously with a high volume fraction and slow coarsening rate (compared to Al(3)Sc). The reader is referred to (M.Sc.) and (Ph.D.) for more detailed information regarding the behavior of Al-Sc-Zr alloys. There is currently very limited use of scandium in industry making it a very expensive alloying addition. Further understanding of its potency, discovery of alternate sources, and increased demand for use in aluminium alloys may significantly drop scandium's price in the future.

Our goals:

Prevention of

recrystallization in some aluminum alloys is increased above the current

limit by adding both Sc

and Zr. Neither element acting alone

can provide this level of recrystallization resistance. Relatively

little is known about Al3(Sc,Zr). Our goal is to continue characterizing

this new Al3(Sc,Zr) dispersoid phase, understand why it is so effective,

and use this information for optimizing its performance. To

accomplish this we are utilizing optical, scanning, and transmission electron

microscopy, microprobe analysis, and a variety of mechanical tests.

The Al-Sc-Zr system may also provide a suitable alloy for studying very

early nucleation behavior which is of interest to a more general academic

metallurgical audience. For this we are planning an experiment using

the ESRF syncrotron.

Recent Results:

Recently we

have been improving the recrystallization properties of an experimental

extrudable Al-Mn-Mg alloy by adding Zr and Sc to form Al3(Sc, Zr) dispersoids.

Both commercial purity and high purity alloys are under investigation.

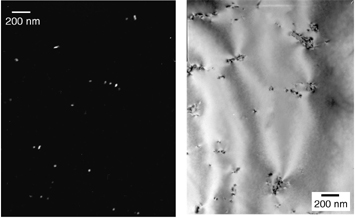

Without Sc addition we find the precipitation of Al(3)Zr following preheating

to be very poor and heterogeneous as demonstrated in figure 1a. No

alternate heat treatment was found to improve the distribution of Al(3)Zr.

With addition of Sc both the distribution and volume fraction of dipsersoids,

Al3(Sc,Zr) in this case, are both dramatically improved as seen in figure

1b. The micrographs in figure 1 are from a transmission electron

microscope (TEM).

|

|

| Figure 1a: Distribution of Al3Zr in an Al-Mn-Zr alloy | Figure 1b: Distribution of Al3(Sc,Zr) in an Al-Mn-Zr-Sc alloy |

After extrusion

these alloys were subject to annealing at 500, 550, or 600 C for 1 hour

and recrystallization behavior observed in the optical microscope using

anodized samples. The grain structures of the non-Sc and Sc alloy

shows markedly different behavior as demonstrated in figure 2. Without

Sc surface recrystallization begins after 1 hour at 500C with complete

recrystallization occuring after 1 hour at 550 C. By adding Sc to

the alloy recrystallization is surpressed to at least 600C for 1 hour with

only a thin layer of recrystallized material forming at the surface.

|

| Figure 2: Optical micrographs of extruded material after 1hour

at 500, 550, and 600C

showing degree of recrystallization |

The details of the current research will be published at the 8th International Conference on Aluminum Alloys in Cambridge, England in July 2002. If you are interested in this research and/or would like more information please contact us. Check back for periodic updates.

Last update: November 13, 2001.