Hayseed, A Miniature Farm Engine

new 12/14/2001, additions 1/26/02 and 2/5/03

I have added a video of Hayseed's hit & miss governor, here.

A few months ago, I took a notion to build my first internal combustion engine. I wanted an old style engine, but since it was my first, something simple seemed in order. A trip through the back issues of Strictly IC magazine yielded Hamilton Upshur's Farm Engine (Mk 2). Hamilton had designed the engine originally back in the early 90's, but since then had made some improvements. Bob Washburn published the revised engine plans in SIC in issues 77 through 79. By November, I had made substantial progress on the engine, and took the still unfinished product to SAMS (The South's own Model Engineering show in Dutton, Alabama). Bob Shores was there with his engines, and I got valuable advice from him and from Robert Russell, a model maker from Childersburg, Alabama.

At the time, I had not worked out the ignition system in my mind, so Robert's advice was invaluable. He uses buzz coils on his engines, and they all run beautifully. Bob had admonished me to "keep it simple", so I settled on a buzz coil and mechanical points. I had a buzz coil that had been on the shelf in my shop for at least 25 years, condition unknown, so I checked out the web for info on buzz coils. That led me to Paul Pavlinovich's site, information on the innards of buzz coils and plans for a buzz coil tester at steamengine.com.au. It is an Australian site and contrary to its title, has information on lots of things including steam engines.

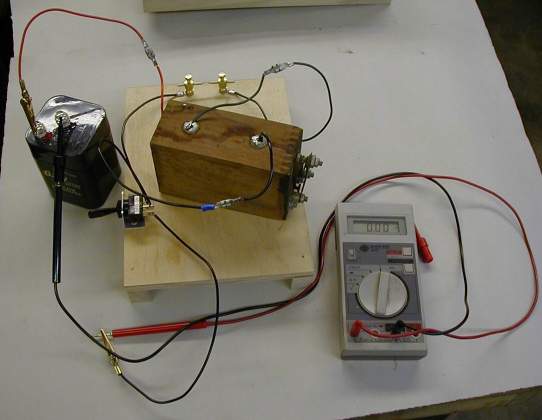

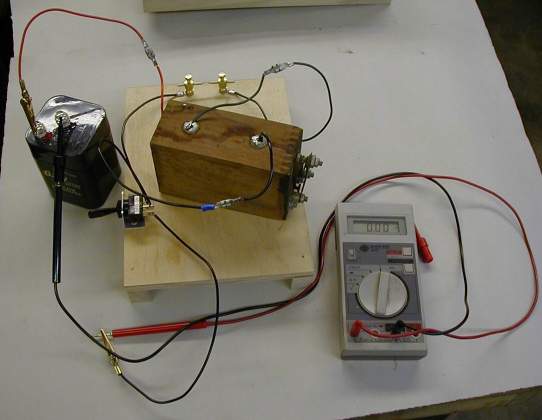

| So, my first step was to check out the buzz coil. Here is a photo of the test layout. My digital meter has a 10 amp scale which makes it ideal for this test. Hardly any adjustment was required, and the result was an intense blue spark across the spark gap. |  |

|

The test bench was simple to make, but quite necessary. It is hazardous to the health of a high tension transformer to be operated without a proper load. If the insulation in the transformer is weak, it will arc over and damage the windings, probably fatally! The only parts I had to make were the spark gap binding posts and the switch bracket. I used an automotive type toggle switch rated at 12 volts, 20 amps, well above the expected amperage of the test setup. The battery is a Radio Shack 6 volt sealed lead acid battery rated at 5 ampere hours. At the time of this writing I have run the engine for about an hour, and the battery is still substantially at full charge.

So now for some views of the engine. As usual, click on the small image for an enlarged view.

This was a fun engine to make, and Hamilton's construction notes are set out

with a beginning machinist in mind. I highly recommend it to you aspiring engine

builders. Strictly IC ended publication with the last issue of 2001, so no more

issues will be forthcoming. Bob Washburn does still offer back issues, so if you

are interested in building this engine, drop by StrictlyIC.com and place an order.

January, 2002:

The engine is now complete. I have made a finger jointed box for it, and have the buzz coil and battery inside. Here some photos:

January, 2003

My first show with Hayseed performing was the Cabin Fever Expo in York, Pennsylvania. Being from the south, I didn't have a lot of tolerance for 4 degree weather, and driving through a snow storm in Tennessee was a traumatic experience. But the show was great and My friend Dewayne Lockler and I were able to find other members of the Florida Amateur Model Engineers (FAME) who we knew by correspondence only. We all stationed ourselves at the same table, and had a fine time comparing notes and admiring one another's models.

I also had the opportunity to meet

Hamilton (Dick) Upshur, the designer of Hayseed. He is a most gracious

gentleman, and free with advice and help. He was pleased to see the engine, and

remarked that he had designed a hit and miss governor for it. I had put the

throttling carburetor on Hayseed to slow it down a bit, but it never was very

happy unless it was running pretty fast. So, I purchased Dick's plan set for

four farm engines which contained the design information on the H&M

governor.

Hayseed. He is a most gracious

gentleman, and free with advice and help. He was pleased to see the engine, and

remarked that he had designed a hit and miss governor for it. I had put the

throttling carburetor on Hayseed to slow it down a bit, but it never was very

happy unless it was running pretty fast. So, I purchased Dick's plan set for

four farm engines which contained the design information on the H&M

governor.

Of course, since I had modified Dick's original design with the larger water tank, I had to make extensive changes to Hayseed to meet the new design. The first order of business was to scrap the large water jacket. then a flywheel modification was in order, and finally parts making and fitting the new governor. I am happy to report that all went well, and now Hayseed putts along in a fairly leisurely manner. I may change the flywheels to a larger diameter, and that should make it even a bit lazier - but that's another project!

Here is photographic evidence of the changes:

| The original |

As modified |

|

|

| The original, complete with large water jacket and silicone fuel line | A slimmer water jacket, exposed pushrod and a more heat resistant fuel line |

|

|

|

|

Right side flywheel, but the left one is identical. |

Left side with governor weights. I left pegs on the ends for springs, but found they weren't necessary. |

|

|

|

| The head and water jacket as originally configured with original carb. | New, slim jacket, the new carb. Brass pushrod guide just below the spark plug. |

|

Some details of the governor. |

|

|

|

|

| Inside of left flywheel showing governor thimble and the rear end of the exhaust valve latch. See above for the outside of this flywheel. | The push rod has a lug that is trapped by the exhaust valve latch. A .006 brass spring holds the latch open until centrifugal force spreads the governor weights and pulls the thimble outward. When the engine slows, the latch is released, seating the exhaust valve and allowing the engine to "hit" |

The modification is a success, and Hayseed will make his next debut at the meeting of the North Georgia Metalworkers ("Metal Munchers") Tuesday, February 11, 2003