Yoda

Here's an email I received from Gary awhile back:

I got it running today!

I had a few snags as I fired up my new motor for the first time. I had small

oil and water leaks, but they were minor. I kept the revs up for a while to

keep the new cam happy. I watched the temps and oil pressure close but it

never had a problem. It would not idle. One big problem with a map based ECU,

the new cam and ported head made it pull less vacum, so the ECU injected more

fuel, but it is actually flowing less air at low revs. I am still programming

it to get it straightened out. It will now idle at 1100 okay, but if I try to

lower it, it starts to hunt up and down about 200 revs. I had this trouble

before with the ISKY cam, and I know what I have to do, but it always takes

time. It is only pulling 15 inches of vacum at 1100 rpm, which is already

kinda low, but at 900 it is only 11 inches of vacum with a lot of reversion

pulsing in the intake, it even makes the PCV valve clatter. I thought I have

a valvetrain noise, but it was just the PCV valve.

I got it running good enought to take for a drive. It feels about how it did

from 1600 to 3500 or so, but from 4000 to 6000 (the highest I hava had it) it

pulls much harder even with only 11 psi of boost. I laid rubber for over 50

feet (the engine shop told me to smoke em) it sounded like a motorcycle. So

much for 22R's not being for performance. With the lighter rotating and

reciprocating parts, it revs freer and shakes alot less. I also weighed my

drive parts before installing them, the HKS flywheel is only 9 pounds and the

Broward pressure plate is nine pounds, the Centerforce one was 11. The

Broward metalic street disk and 1700 pound pressure plate work great, it was

a bit grabby at first (it took some getting used to) but now I can luanch it

with now chatter and it never slips.

My first trans re-build also works great. I can get it into second so fast

that the revs don't fall, and the boost is still there after the shift. When

I did the burnout it left 50 feet of black streaks, then 6 feet clear, then

another 10 feet of black after the shift, then I lifted as the street is a 25

mph zone. I had blue tire smoke all around the car.

Soon after though, I had steam all around the car. The rear freeze plug on

the passanger side blew out, dumping all of the coolant in a few seconds. I

noticed the steam and the temp gauge climbing, so I shut it down and it took

me a while to figure out what happened. I was a little luck as this plug is

is one of the two I could get to out of 5 in the motor, without having to

remove alot. I still had to take out the oil pressure sender and oil filter,

but it was still under the intake, over the starter, and infront of the

bellhousing. I finally got the new one in with an air chisel. I used a piece

of aluminum to take the chisel pounding and spread it out to the surface of

the plug. I tried all different ways to swing a hammer in there and gave up,

the chisel worked great.

By the seat of the pants dyno, I would bet it will do low 13 second 1/4 mile

times right now with just 11 psi of boost. The ultra fast shifts and the

tremendous top end power boost sure make the 14.0 run I did feel slow. Maybe

high 12's, but I don't want to speculate. I will probably get it on a dynojet

next week to dial it in the rest of the way. For now it is a bit rich and

idling too fast. I had to add over 20% more fual at 6000 rpm to keep up with

the greater air flow, at the same boost as before. The 40 pound fuel

injectors are definately the limit now. Even with the pressure kicked up to

52 psi they are topping out at 12 psi.

Gary Meissner

Boost Rules !!

Here's another update I received from Gary but unable (read: busy/lazy) to put up on the site until now:

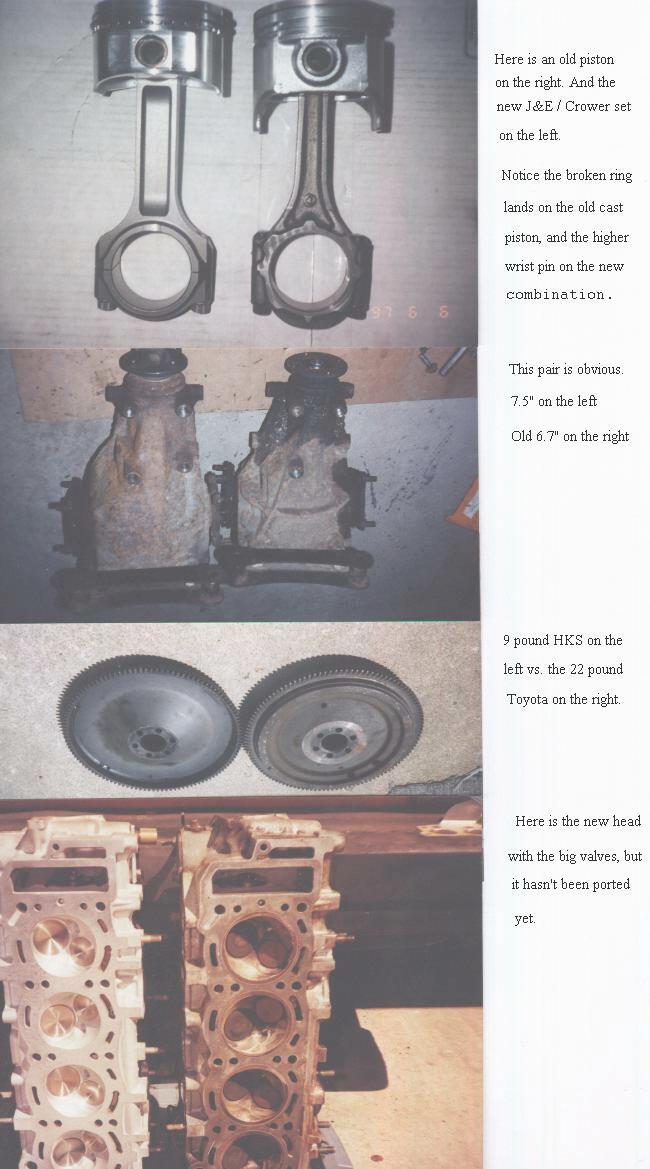

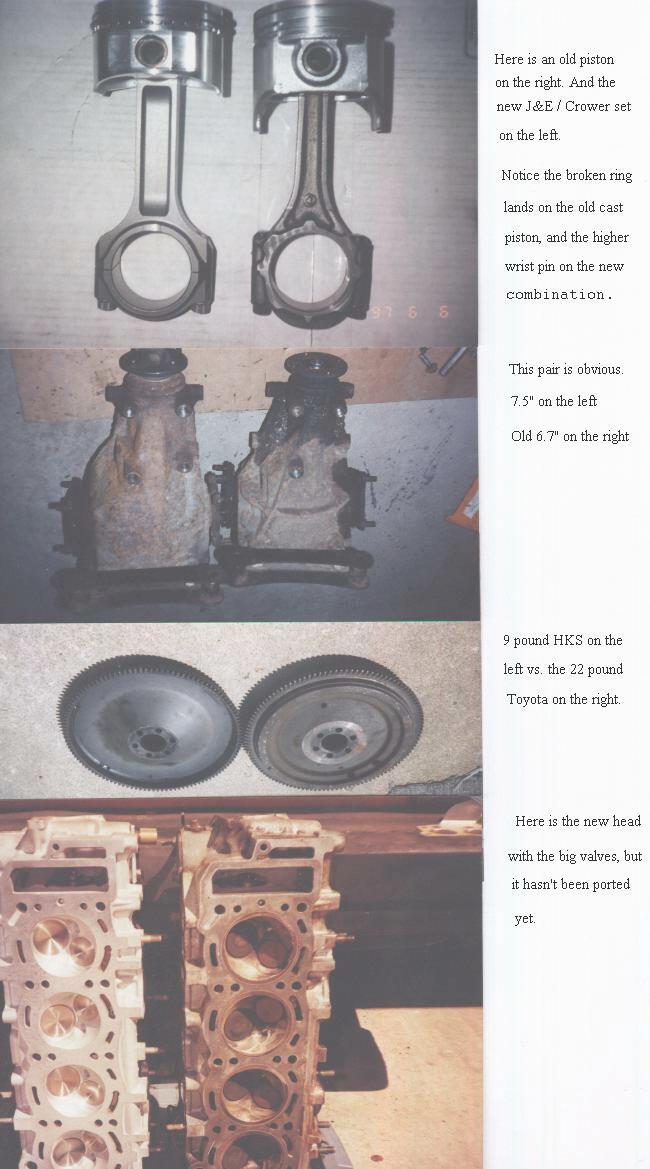

The highly modified 22RE sports J&E forged pistons and Crower billet steel

rods. The valve train is activated by a Comp Cams 268S through Toyota

Aluminum rockers on LC Engineering heavy duty shafts, and the valves are

oversize Ferrea stainless steel parts.

The turbo system consists of a custom Turbonetics built TO4E/T-3 Hybrid

blowing through an intercooler consisting of two Renault Fuego cores, an HKS

blowoff valve, a Buick 2.3 inch throttle, and a hand made plenum that

shortened the stock intake runners to about 10 inches long.

Fuel Regulated to 52 psi by a modified Toyota regulator, is fed to this beast

by a Bosch GFP 286 fuel pump, and set of Bosch Porsche 944 Turbo injectors.

Controlled by an Electromotive TEC II running super blend software. The TEC

II also takes care of the spark with it's direct fire ignition system, which

uses a crank trigger, and eliminates the distributor.

Gary responded recently to a ToyModder who was seeking advice on using the turbo from an SVO Mustang on a 22RE:

Disclaimer: Neither Gary nor I claim responsibility for anything that could go wrong should you attempt to do this.

Q:

The problem I'm having is with the way the turbo assembly is made. I

am stuck putting the turbo in one direction only because I want the oil

to go down,using gravity,into the pan (I was told that's the way to do

it). When doing this, both nozzles are pointing toward the engine block

!

Now my question: Can I rotate the compressor (the hot side) of the

turbo assembly so the nozzle points in the direction I want to. There

is only six bolts which attaches the housing to the center assembly. I

know I will need to change the gasket. I am just not sure if by

rotating the housing I will screw up something.

Any info on the matter will be appreciated !

A:

When they get old and a little rusty, the housings can be tough to turn, but

all you have to do is loosen the six bolts on either housing and it can be

rotated from the center section. The oil drain must face straight down. The

stock Ford outlet elbow off of the exhaust housing may also be a problem,

since it will face in a given direction from the exhaust inlet. I think it

will be the wrong way for you, as Ford has the exhaust come in frokm the left

and then the exit faces down. This is as viewed while sitting in the drivers

seat. I used a garret outlet that exits straight out the back, but then I had

to bend a fairly tight S to get it under the floor.

As far as turning the housings, just try to take them off, if they won't

turn. The exhaust (cast iron) side, has no seal at all, just a sheet metal

shield that goes between the two cast iron parts and kinda seals it when they

are clamped together. On the intake (aluminum) compressor housing, there

could be an O ring, or a paper gasket, depending on the version. I had one

with the paper and I just used a very thin layer of silicon when I put it

back together. If the housings won't move easily (very likely) you may need

to remove all 6 bolts and soak the joint area in WD-40 or another penatrating

oil, then use a soft face hammer to smack the housing, while you hole the

center section. If there is not enough clearance to remove the bolts, just

loosen them back as far as you can, and then when it moves that far, you can

back them out some more. A propane torch on the housing may also help loosen

it up. My friend even resorts to Acetelene and a BIG hammer.

GoodLuck,

Gary M.

Gary Meissner

Back to Yoshi's Friends

Copyright 1997 Tom Kyle and Gary Meissner, photos courtesy owner