'89 YJ front Dana 44

('65 Ford "Closed Knuckle" 8-Lug 3/4 Ton)

Purchased this axle for $75.00

Who wants a closed knuckle anyway?

So I figured what do i have to lose

and decided to narrow it myself.

(well almost by myself)

After cleaning and inspecting I

decided it was in good condition,

had 19-spline shafts and a 4.56 ring

and pinion.

I installed 2, 15 x 10" steel wheels

to take measurements off of and

decide how much to narrow the

housing.

I left the drivers side alone and

shortened only the passengers

side, (6" exactly). So the driveshaft

isn't exactly aligned fore/aft, and it's

a little closer to the engine oil pan,

but it's not very far off.

After removing the brake drum,

spindle, kingpins, knuckles and axle

shaft. I marked the housing in-line

with the kingpins, (so i could get the

caster back correctly). measured

twice and cut the closed knuckle

and 6" of housing off with a hacksaw.

I carefully cut and ground most of

the tube off the knuckle/ball, it has

about a 2 1/2" shoulder thats pressed

into the tube. I took it to a local

machine shop and had them machine

the rest of the tube off the ball

shoulder down to 2.000" (the same

as the inner diameter of the housing)

I re-installed the knuckle in the tube,

by lining up the caster marks and

hammering it into place with a 10 lb.

sledge. (it fit very very tight)

I took it down to another

local welder and he put

a great weld on it (3/4 ton

44 tubing is almost 1/2"

thick) it's not coming

back off very easy.

I will post pictures later...

The pearches, spring

pads, and differential

housing reauired some

grinding. it was a spring

over and I wanted a spring

under. I also custom made

some U-bolt pads to get

the springs as close

to the housing as possible.

I put it all back together and

so it was time to try to align

it, (and see how for off the

knuckle is) I just used a tape

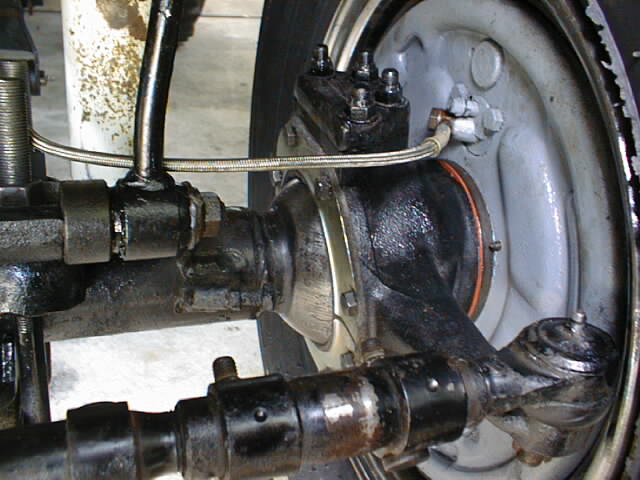

These 2 pics

during the

installation,

they are

after i

norrowed

the housing

but before

welding the

pearches

and hangers.

measure and a couple levels. First I mounted the wheels (no tires) and hooked up my factory YJ

tierods and adjusted the toe in-out. Then i put levels on the outside of the wheels check the

camber (leaning in or out) Then i took a guess and went to NAPA and got a couple camber shims,

(they are tapered shims that bolt between the spindle(backing plate) and knuckle, they are

orange in the picture). You have to know what degree shim to order, i guessed and was wrong

the first time (NAPA let me return them and get some others). So you can install this shim about

6 different ways getting more or less camber, but it also adjusts toe in-out. (it took quite a few

times to get it right) Next was the axle shaft, (narrowing only the one side means only one

custom $haft) I took the factory shaft to the machine shop and they cut it in half, took out 6

inches machining male and female ends before welding it together. I plan to have one custom

made, I'll probably wait until I'm broke in the woods. Anyway I installed some tires and a drive-

shaft and i was ready for a road and trail testing, It works fine and I'm already planning some

upgrades, first on the list is a locker, I'll get a "Lock-Right" or maybe that new "Gearless locker"

after the first of the year.

Other stuff:

1. Replaced all 4 kingpin bearings and races, (from NAPA) and then reshimed the kingpins.

2. Replaced felt wipers and seals that keep dirt out of Knuckles. (from J.C. Whitney)

3. Cleaned and regreased wheel bearings.

4. installed Superwinch locking hubs.

5. welded lower shock mounts behind axle and out of harms way.

6. Installed extended steel braided brake lines.

7. Drilled holes through the wheels, mounted the tires and installed some beadlock screws.

8. I'm still experimenting with caster, closed knuckles don't have a vary tight of a turning

radius so I'm going to put some shims between the springs and axle pads to make some

negative caster. (It's a trail Jeep, tighter turning is more important the street manners).

"Future Plans" Locker and 30-spline axle shaft along with some Warn Locking Hubs.......

Well that's basically it. (I have more pictures to add and i'll re-write some of this later, I know

i'm not the most literate "Jeeper on the Trail")

This is the first time i ramped it after

the Dana 44/Shackle reversal swap, it

had no lockers, and my winch wasn't

installed but it did OK, I think it scored

about 850 or 900, the rear tire missed

making it onto the ramp by about

3 inches or so.

Jeepers since 24 November 1999

back to 3/4tonYJ's main page