Ubiquitous sprayers range from squeeze bottles through garden hoses to immense aeration systems, but very few are adaptable to hobby usage.

Early in the 50's, spraying equipment was not available in hobbyshops, although airbrushes were occasionally mentioned in magazines. The first affordable sprayer offered was a flexible bottle with a crude spray head, similar to present spray cans. After some practice, it coated better than brushing but was very difficult to aim and control with only the driving squeeze to "regulate" pressure. It was excellent for exercising fingers. Next an article suggested using a perfume atomizer, which also exercised the fingers. It spayed, but not well. Before I got muscle bound fingers, relief came through the mail in the form of a handy-dandy vacuum cleaner attachment. Although it was larger than expected and more suited for standard gauge, I managed to spray a fair number of cars with decent finishes. The squeeze bottle was kept in reserve for finer work.

While traveling in 1963, I stumbled across an artist's supply store with a display of Paasche air brushes in the window. After a lengthy discussion with a doubtful salesman, we agreed the H-3 kit with three tips, some hose, two pressure cans, a couple of bottles and regulator adapter was the way to go. A regulator/moisture trap was added, just in case. Since there was no local source for the relatively expensive pressure cans, a less expensive, 50 psi max, garden sprayer tank replaced them. A few trial sprays at 50 psi on a humid day convinced me that the regulator/moisture trap was an absolute necessity. As a body builder, the transference of exercise to the triceps was acceptable. Later, after serving many years for its original intended use, the tank died; but the airbrush and accessories still see frequent use. With only very infrequent replacement of O ring seals, can this be construed as durability?

Today better hobbyshops offer a wide display of sprayers, but unfortunately through proprietor's lack of knowledge and experience, not all are acceptable. Too often advice and recommendations are not worthy. By understanding the principles and characteristics that meet your requirements and budget, a wise selection can be made.

Aerosol spray cans are the least expensive entry point for coat spraying, but in long term use with a large number of spray jobs, economy soon fades. They eliminate bottle paint selection problems, but introduce their own. Ideal for quicky jobs, they are available in a very extensive range, for spraying almost any liquid. Expensive, refillable versions exist. Those suitable for hobby use are very limited by more stringent requirements. Nozzles, pressures, vehicles, and pigments must be adapted. In early development, paint often spit, sputtered, varied in coverage as pressure dropped, dripped from nozzle and stopped from clogging. Today nozzle design has greatly improved and seems to have standardized, but subtle differences occur in the stems. Being a take what you get situation with no adjustment except distance and pass speed, they are often difficult to control in more demanding work. At one time Floquil offered a three step, twisting adjustment to control pressure and paint volume simultaneously. Too often the can's location interferes with spraying motions. Another major drawback is that custom colors can not be mixed. In spite of their limitations some very good finishes have been produced by experienced users. Clear and translucent coatings spray better than pigmented. On occasion Testers Dullcoat and Floquil Instant Weathering are used for quicky jobs, when I am too lazy to fire up the spray booth. Within their limits, most techniques are similar to airbrushes.

Good airbrushes are the ultimate sprayers , but they are not all created equal. Often, with necessary accessories, they present a sizable investment. Quality, cost, utility, performance and beauty vary drastically. Understanding how they work can be a great aid in selection and operation. Before selecting a sprayer, the basic principles of SPRAY PAINTING _ should be thoroughly understood.

Airbrushes have been in use for centuries. Probably derived from an early practice, among monks, to blow pigments or metallic powders from the palm of the hand onto wet sticky figures on manuscripts. The addition of a straw was found to improve the aim and reduce waste. Later Bernoulli deduced the principle that a fluid flowing past a hole induces a vacuum in it, whose magnitude increases with the flow velocity. Also Venturi stated by constricting the cross section of the conduit, the flow velocity increases to maintain flow rate, thus increasing the vacuum in the constriction. Modern carburetor jets rely on these principles. Lung powered, early airbrushes consisted of a blow straw and a siphon straw, affixed so the open end was in the exiting jet stream of the blow straw nozzle, creating a vacuum. With the other end immersed in a liquid pool, atmospheric pressure forced fluid up the siphon straw to the nozzle. Some time later lungs were probably replaced by foot powered bellows. All modern airbrushes use these principles with variations in locations of the vacuum orifice and possibly a means to control the vacuum and flow. In some cases, increased pressure is applied to pool surface to increase flow for batch processing and heavier media. In others the pool level is raised above that of the nozzle to gain an assist from gravity.

Beyond the artist's airbrushes commonly used in modelling, they take many forms. Common industrial airbrushes are automotive paint guns, painter's spray guns, and automated types including a radial multi-nozzle head used to spray the insides of large pipes. More crude are the common triggered spray bottles and the old piston Flit insect sprayer, which exhibits the early tube method plainly. Often tried as an alternative, most atomizers are essentially airbrushes.

Most artist air brushes have removable caps or hoods enclosing nozzles, which help form spray cone and protect delicate pointed tips. To ensure proper pattern formation, cap must match nozzle.

The first division of any sized airbrushes is internal or external mix, with the former occurring outside, after the the nozzle, and the latter inside, before the nozzle. Internal increases the possibility of paint clogging tip, if drying commences due to the mixing of paint and air. Cleaning is also more involved. In spite of claims, from experience, there is almost no perceptible difference in the quality of spray produced by either in brushes of equal quality. Externals are usually less expensive due to simpler design. Often they do not include adjustments.

Better brushes have spring loaded air valves to turn either on and off or to adjust air flow. On smaller types, a finger button is used, while larger use triggers for fingers or thumb. Some artist types provide a screw stop, stipple adjustment, which limits air valve opening and derives its name from a technique used by commercial artists to produce very tiny dots, through low pressure and flow application at a short distance. It can be used to set maximum air and fluid flow. Although it is difficult, some experts claim they can control flow effectively by varying button depression.

The second division is single and double action. In the first, medium flow rate is set prior to application, while the latter permits rate changes in the midst of passes. Offered by Paasche, well over 80 years ago, with apparently only cosmetic and slight precision improvements, the most popular cone tip type has an external shell cone covering a fixed interior one. Flow adjustment is by screwing the outer cone to vary the spacing between them. Often classified as external, this seems nebulous, since the paint orifice is about midway along one side of the inner cone and surely some mixing occurs inside, before nozzle is reached. This type can handle almost every properly mixed, sprayable medium with ease. The second common type is derived by replacing the inner cone with a solid needle, whose insertion is controlled by a screw arrangement at the rear of the handle. The outer cone is usually smaller and with the more gradually tapered needle, a finer spray cone should be a result. Too often this is not the case, due to inferior design, machining and quality control. Since these are definitely internal mix, with paint orifice well behind cone tip; they tend to clog more often. Very often some will not handle common model spray mixtures.

Derived from the needle type, in the double action the air valve stem is articulated below the needle. By a fore and aft movement of the air button, the spring loaded, needle insertion and flow rate can be very easily varied during a pass. Better quality models have a screw, vertical stipple adjustment, in front of the stem, which permits settings similar to single action for steady base coat applications. Double action permits very easy shading and edge feathering plus many weathering techniques. With more difficulty, almost all these techniques can be duplicated using a single action brush.

As with buying cars, any advice in the selection of airbrushes is bound to be controversial, due to prejudices and personal preferences. Having used airbrushes since 1963 and sold them since 1969, statements are based on feedback from customers, personal experience or observations and discussions, often with professionals. We have stocked almost every suitable, common brand and model including some imports. Consistent with our policy, samples were tested before stocking in depth. Many were returned as defective or inferior. But the best advice and airbrush in the world can not produce good results, unless the user learns how to tame the beast. Bear in mind that these comments are not gospel, but my own learned opinion.

With all the variables, selection can be complicated and mistakes can be costly. Bearing in mind the factors above and determining the proposed applications, techniques, flexibility , speed, quantity and quality can narrow the choices. An important consideration is availability of required or desired accessories, which will add to expenses; such as air supplies, regulators, moisture traps, hoses, siphon bottles and spare parts. Many of these, from different sources, are not compatible. For long term use, future expansion capabilities, including changeable tips, should be considered to avoid obsolescence. Compare against alternative methods. It makes little sense to invest in an expensive airbrush system for casual use, when far less costly methods may yield satisfactory results. Other possible uses may influence decision and convince you wife. Hobby applications include miniatures , doll houses, doll faces, dope on planes, epoxie paints on boats, water colors on wedding cakes, military models, vehicles, ships, ceramics and automobile touch-up.

At the risk of being shot, sued or ostracized, certain pertinent criticisms should be presented. The most common needle airbrushes found in hobby shops, Badger, do not spray many acrylic or solvent paints well. Too often they sputter and clog, possibly from design or poor machining. Paint seems to collect around needle and tip, effecting spray pattern. The newer clone, H type clones spray much better, but not as well as the original. With most media, Binks brushes perform well, while Thayer-Chandler is better. Most other brands, including imported, seem to be directed more toward commercial artists, handling inks and lower viscosity media well. With some, newer to the hobby field , feedback is too scant to form a judgement.

Since 1969, well over 80% of the airbrushes sold in our shop were Paasche from the finer cone tip F-2 to the AB, considered by many to be the finest airbrush ever made. By far the most popular airbrush, with the fewest negative comments, was the Paasche H-3 with all 3 tips. Many beautiful, contest winning quality, finishes were created with it in many hobby areas; including weathering techniques. It sprays epoxie paints applied to fiber glass model boat hulls very well. In one case, even latex wall paint was sprayed successfully with the #5 tip.

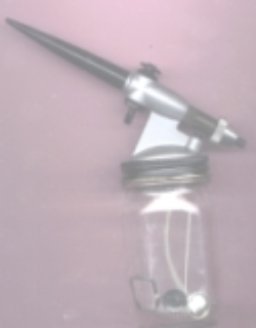

Note: Adjust brightness and contrast for optimum viewing.

PAASCHE H-3 SINGLE ACTION, 1963 VINTAGE.

Modified baby food jar adapter.

Those who required the flexibility of double action, placed the Paasche VL-3 in a solid second place. With spraying ability similar to the H, it performs similar duties with easier application. A large percentage of VL's were sold to commercial users for painting fancy decorations on automobiles and motorcycles, signs, murals, teeshirts, antiques and floral arrangements.

Note: Adjust brightness and contrast for optimum viewing.

PAASCHE VL-3 DOUBLE ACTION, 1970 VINTAGE.

Surprisingly in third place was the low end, Badger 250 sprayer with the larger bottle. Spraying water based media well with a broader coverage and cruder adjustment, applications included scenery dyes, misting powder-ballast mixtures, matte medium, and white glues for turf and foliage and other wetting chores. Not very critical, a small compressor, pressure cans or a portable tank can be used,

Note: Adjust brightness and contrast for optimum viewing.

BADGER 250 SPRAY GUN

Blending pigments into hydrocal for hardshell scenery tends to weaken it and produce too even coloring. Mixing saturated water solutions of common household dyes in jars to maintain constant color bases, they can be mixed and sprayed sloppily and variously, on set and dried plasters, to reproduce the randomness of nature. Tintex gold, neutralized with a small amount of purple, closely matches the gravel found throughout South Jersey. Lighter spraying produces dry sandy areas, while heavier yields darker damp areas.

Quite messy, requiring a catch vessel at bottom, a very thin mixture of plaster can be poured, onto a hardened shell, from the top and permitted to follow its own course, creates washouts and erosion effects. Following this with an application of water will produce natural cuts, caused by run-down. When set, pouring dye solution in the same manner will darken damp areas more naturally.

Abrasive blasting is another type of spraying, commonly used in model preparation. A couple of mini-sized types are available in hobbyshops, but for efficient use with faster cutting abrasives, at 35 or more psi, common compressors are not sufficient. A large aperture, metal nozzle, Brown Sandblast Gun does not permit finer work for erasing and wastes abrasive. Maximum pressure is 45 psi, but at lower pressures, siphon feed is not sufficient with heavier abrasives. Paasche's siphon/gravity feed, fine nozzle Air Eraser can produce delicate work. With 30 psi and their protein abrasive, erasing on paper or removing lettering is practical with some practice. At 45 psi, faster cutting carbide abrasive can remove paint, undercut solder and etch brass for tooth in painting. To avoid clogging feed, re-used abrasive should be sieved. All abrasives should be very dry. The long lasting, carboloy tips are highly recommended for use with fast cutting abrasives, which wear metal tips rapidly.

Note: Adjust brightness and contrast for optimum viewing.

BROWN SANDBLAST GUN

Note: Adjust brightness and contrast for optimum viewing.

PAASCHE AEC AIR ERASER, 1971 VINTAGE

For larger work, a blasting booth, with larger nozzle and pressure, should be used to save time. Several are available at under $100 US. Ours is a wooden version with sloped Plexiglas lid, exhaust fan for better seal and an on-off foot switch. Abrasive falls to bottom bin for syphoning. Spraying is crude, compared to the AEC, but effective for large work. Air is supplied by a large 125 psi compresser through a regulator.

Image to come.

BACK TO PREP

BACK TO PAINTING

BACK TO METHODS INDEX

BACK TO TOOLS INDEX