Although circular blades can be used for some outside trimming and concave dishing, they a primarily designed for fast accurate, straight line cuts. To perform well the must be securely and rigidly mounted on closely fitting mandrels, arbors or bushings on shafts with minimum wobble and runout. Any play in the system will widen the kerf. Very thin blades are susceptible to bending, which may jam them. Use of quality bench machines can avoid the problems . Speed control is essential to avoid overheating, which may soften or melt plastics, or burn wood and blades, Although slower cutting, Finer teeth should be used on metals and sheet stock.

Shared by many of the modelling sized saws the nominally 2" (50 mm) blade with 10 mm mounting hole is available in fine slitting, coarser wood, carbide tipped and diamond coated forms plus thin abrasive cutoff wheels. Very common in the metric world, they are a little difficult to find, at a reasonable price, in the USA. A few adapters can be found in Europe, but importers fail to recognize their value.

There is a fair variety of ROTARY TOOL SAW BITS _that may be used for quick freehand cuts. These are all mounted mandrels, fixed or changeable. Frequently they can fit in tight spaces, where others will not. Diameters range up to about 2"

DANGER; _These can cause

severe cuts and injury, if used improperly

DANGER; _These can cause

severe cuts and injury, if used improperly

The Minitool right angle unit can be used as a portable saw. The forward rim of the circular guard is truncated to expose the edge of a saw blade or grinding wheel. Minitool has an adapter for mounting both, which is included with some of their 2" saw blades. Neither importer, Sears nor Micro-Mark saw fit to import them and Minitool does not sell direct. Since almost all small imported circular saw blades have a 10 mm mounting hole and the OD of the screw-on sanding pad shaft is, ironically, 10 mm, one can be easily made for the price of a pad and a few nuts.

Note: Adjust brightness and contrast for optimum viewing.

MINITOOL RIGHT ANGLE UNIT AS SAW

Edge of blade can be seen at the left of shield.

Using the vertical column, the Unimat and some other screw machines can chuck mandrel or arbor mounted blades. This permits extremely accurate sawing in almost any position at almost any angle, unattainable by other methods. In addition to the rotary tool bit types, blades of almost any reasonable size and type can be adapted. Work can be securely clamped to the table and carefully and accurately positioned by the feed screws. Sufficient power is available for almost any modelling work. The major drawback is that it takes much more time to set up than to do the cutting.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT COLUMN SAWING

A special arbor threads onto spindle screw. The bushing is trued on the machine while turning to size to fit the required blade mounting hole. The same mandrel is used on the C5 milling machine but with a shank for mounting in chuck.

Note: Adjust brightness and contrast for optimum viewing.

C5 MILLING MACHINE MANDREL

Among the smallest table saws is the 12 V DC, Maxicraft with 4 1/2" x 5 1/2" split table. The right hand section is spring loaded to operate a safety switch, which powers motor only when pressed down by work. It accepts 2" blades with 10 mm holes. The hinged table tilts up for access to arbor and to empty debris. An adjustable fence is clamped to the calibrated table edge. A simple splitter and guard extends over blade. It cuts accurately but with thicker sheet tends to kick circuit breaker on standard power pack; however with heavier packs, it works well.

Note: Adjust brightness and contrast for optimum viewing.

MAXICRAFT TABLE SAW

The AC Proxxon table saw is a more robust unit with a x" X x" surface with Both an adjustable fence and miter guide. Also accepting 2" blades with 10 mm hole, it cuts well, but is too fast for some plastics and will be modified with a triac speed control. Possibly an oversight, since their scroll saw seems to share the same base housing.

Note: Adjust brightness and contrast for optimum viewing.

PROXXON TABLE SAW

Before any modifications.

Dremel offered a 4" blade, 45 ° tilting, AC, table saw designed chiefly for wood. Due to tilting the blade slot is wide, for clearance. Blank replacement plates are offered to narrow slot for finer blade and narrow strip cutting use. A kit is also available to improve performance. Blade uses common 1/2" mounting hole.

Note: Adjust brightness and contrast for optimum viewing.

DREMEL 4" BLADE TABLE SAW

45 ° tilt.

The original Unimat saw table has a rather crude 3 1/2" X 4" table with two blade slits and a bar stock fence that could be set to some small angles. It is mounted by vertical post in a hole in a bracket which is clamped on the carriage. By pivoting around the post, blade to slot alignment can be set. While vertical post adjustment set the blade exposure above table. Final adjustment of blade in slot us done by feed screws, Using the standard arbor, the blade cut line barely cleared the end of the motor. Blades were limited to about 2 1/2" to clear the ways. With the low speed attachment mounted the motor could not be dropped enough to clear wide sheets, unless the head stock raising block were used or the unit were mounted on sheet a 3/4" plywood to permit the pulley to drop below the bed base level. With a headstock raising block, a 3 1/2" blade could be used, In the end very precise cuts can be made, if the right blades were found. Standard blades have a 16 mm hole. Unfortunately the arbor screw is 12 mm preventing use with more common 10 mm saws. However using a chuck, 1/8" mandrel , Gyros fine slitting blades can be used.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT OB200 TABLE SAW.

Later a new 6" X 8" table was developed for the Unimat SL, with a blade guard, a fully adjustable fence plus longitudinal and cross slots for an angle guide. With a new design of motor brush holders the head stock raising block was definitely required. The mount is very similar and the arbor remained the same.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT SL TABLE SAW

Having become quite popular in construction work, a model sized AC miter chopper saw is available for cutting strips, rods, tubing and structural shapes at angles. Accepting 2" blades or abrasive cutoff disks with 10 mm hole, almost any material can be chopped fairly cleanly. To clamps items securely, a 7/8" opening miter vise is mounted on a rotating base with recess to clear blade. Although light deburring is usually required, it is far better than a tubing cutter, when making critical tube spacers for steam loco rods or drive trains, A speed control is highly recommended for low melt plastics .

Note: Adjust brightness and contrast for optimum viewing.

MITER CHOPPER

BLADE SELECTION

Modelling sized blades are a little difficult to find, due to nonstandard mounting holes and limited market. Of course if you are affluent enough, bushings, mandrels and arbors could be made. Due to stability reasons, slitting blades for splicing, thinner than .020 (.5mm) in the 2" range, are not found. SELECTION OF OTHER BLADE PARAMETERS_ is covered under Power Saws.

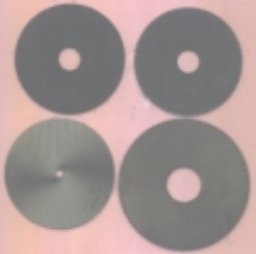

Note: Adjust brightness and contrast for optimum viewing.

HOLE SIZE COMPARISON OF CIRCULAR BLADES.

Proxxon abrasive .028 kerf. 10mm hole.

Proxxon .016 kerf.10 mm hole.

Gyros .014 kerf. 1/8" hole

Unimat .031 kerf. 16 mm hole

USEFUL LARGER SAWS

Portable and very handy around the layout, for straight trimming sheets and cutting legs, joists, risers and cleats; the circular saw is faster and more accurate than a saber saw. They can cut bevels and, with a guide, trim even slivers. A very wide selection of blade run from veneer through cross cut, ripping to carbide tipped. Available are many metal cutting and abrasive including masonry and diamond. Sizes run from about 4" on up.

Note: Adjust brightness and contrast for optimum viewing.

7 1/2" PORTABLE CIRCULAR SAW

BACK TO POWER SAWS

BACK TO TOOLS INDEX