Some early bench top, jig (scroll) saws were developed with a same principle as the Dremel hand saw, with the vibrator below a fixed table and the spring on a bent rod support. The cutting area of the blade was near the lower end. Rigidity and spring were usually insufficient to create enough tension to prevent blade wandering, during any side thrust. Accurate cuts were very difficult to attain. Most of the larger, inexpensive saws were of the same design. One of the disadvantages of almost all these saws is that only a small length of blade is used and worn. The remainder is usually wasted.

There is one factor associated with all these tools that limits the size of the work piece. That is the distance from the blade to the rear of the arm, known as the throat. Once the piece hits the arm no additional cutting can be done along the line between the blade and the arm. To permit cuts longer than the throat, some blade mounts allow blade clamping at perpendicular to the throat lime. But then the width of the piece is limited by the throat.

Used on more expensive models, walking beam types had a overhead lever that moved synchronously with the lower cam, maintaining tension and distance between ends of blade. Yet with jeweler's blades, wandering still occurred. Less expensive types rocked the entire arm, which in turn rocked the blade slightly.

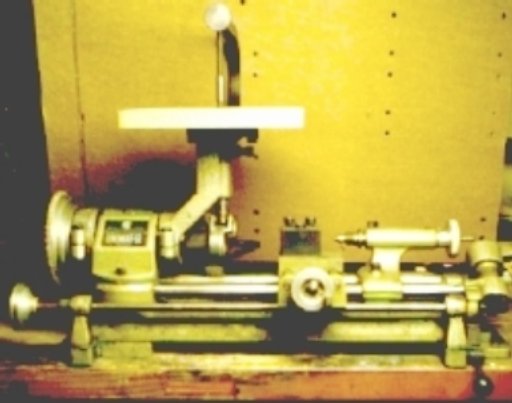

Dremel introduced their first table jig saw using the 4" pin blade and a tilting table, apparently for wood only. The upper pin holder tightened blades through a lever operated cam. Side play was a problem in fine work. No speed control was provided.

Note: Adjust brightness and contrast for optimum viewing.

EARLY DREMEL JIG SAW

Later they introduced a slightly beefed up model with larger table, longer throat and a power take-off for a mediocre flexible shaft tool. Essentially the remaining characteristics were the same.

Note: Adjust brightness and contrast for optimum viewing.

LATER DREMEL JIG SAW

Many attempts were made to introduce low priced saws, which overcame some of the deficiencies, including cam drives coupled to rotary motors and improved guides for use with jeweler's blades.

Unimat offered a unique solution for handling jeweler 's blades, consisting of a below table cam operated blade clamp and on an overhead arm, a vertically adjustable slotted rod; in which the blade is free to slide. With the lower end just clearing the surface of the work piece, it served as both hold=down and excellent stabilizer. Unfortunately with very thin blades, a little too much side play was permitted. A decided advantage is that most of the blade could be used by snapping off a sufficient length to lower worn area below table and re-clamping.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT SCROLL SAW

8" throat

Support and cam below table with open access to lower clamp.

Note: Adjust brightness and contrast for optimum viewing.

HOLD-DOWN GUIDE (closeup).

Jeweler's saw blade in slot.

Proxxon later introduced a spring loaded saw with a sewing machine like, foot hold-down, mounting a small vee cut, pulley type wheel as an excellent stabilizer. Limited to almost full length jeweler's blades, it wastes most of the unworn section and breakage loses the whole blade. Access to the lower clamp is through a removable door at the right with a long Allen wrench. A light source and an eye-level view are required, necessitating either a clear bench with face near it or up-ending housing. Aligning blade between the clamps and in the pulley groove is a bit tricky at first. However once set up it does fine work very well; but in spite of the fence and guide, long straight cut must be leveled afterward. The speed control works well with plastics. A blower attachment keeps blade in view.

Note: Adjust brightness and contrast for optimum viewing.

PROXXON SCROLL SAW

12" throat.

Old pencil sharpener clamp secures wood base to bench edge,

Note: Adjust brightness and contrast for optimum viewing.

FOOT, GUIDE WHEEL AND BLOWER TUBE

For the connoisseur with a large pocket book, there are several larger, more expensive models available.

BLADE SELECTION

Excluding the Unimat, since both ends of blades are clamped and most saws accept only one, length is the most critical parameter. In addition, although most will clamp flat tangs , some require pins (Dremel) or holes. A simple pin substitution can be made from a 1/8' steel rod by slitting across the middle about 3/32" deep, then by drilling and tapping, from one end, for a 2-56 screw. As substitutes , a few abrasive coated blades, including diamond, are available. Abrasive cords and ribbons can be effectively clamped in most. SELECTION OF OTHER BLADE PARAMETERS_ is covered under Power Saws.

Note: Adjust brightness and contrast for optimum viewing.

SIZE COMPARISON OF DOUBLE END BLADES.

Fine Dremel 4" pin.

Coarse jeweler's 's

BACK TO POWER SAWS

BACK TO TOOLS INDEX