Over the years the Unimat in various models has provided the hobbyist, jeweler and and other miniature machinists with a very versatile and accurate tool. Convertible from drill press, mill and lathe through jig and circular saw, to grinder, planer and shaper with accessories and a little cost in setup time. Since only a less versatile CAM version is produced, finding a good, used unit can provide a totally new dimension to your modelling.

Note: Adjust brightness and contrast for optimum viewing.

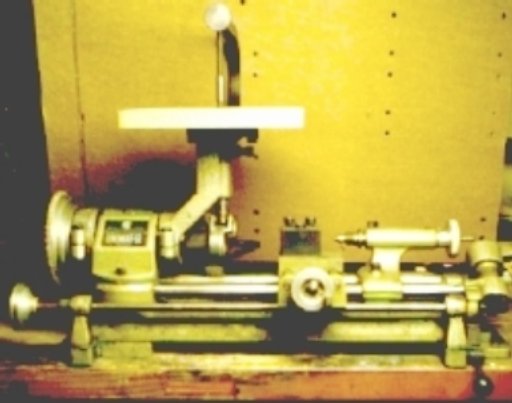

1952 DB200 setup for drill press and vertical mill.

The mainstay until 1971, when we obtained a Unimat distributorship and a Unimat SL was acquired. Instead of selling at a low price, the unit was permanently setup for milling and drilling. Still in use, it provides a very accurate and sensitive drill press and mill.

The Unimat SL provided a more robust lathe and a wider variety of improved accessories.

It has enough power to handle almost any hobby sawing very accurately with the correct blades. Since the space below the table is open, access to clamp is relatively easy. It has been used to cut and shape brass drainage fittings to make ferrules to mount a sailing mast on a canoe thwart. Accurate cutting with larger saws was impractical to set up.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT SINGLE ENDED BLADE SAW

Note: Adjust brightness and contrast for optimum viewing.

Unimat SL jigsaw setup.

This is a very fine jig saw setup in which the upper blade slides in a slot in the hold down rod. Only a very small portion of the blade is free, which drastically reduces side wandering. Added advantages are reduced breakage and almost the entire blade can be used by snapping off the lower worn section and rechucking.

Using the vertical column, the Unimat and some other screw machines can chuck mandrel or arbor mounted blades. This permits extremely accurate sawing in almost any position at almost any angle, unattainable by other methods. In addition to the rotary tool bit types, blades of almost any reasonable size and type can be adapted. Work can be securely clamped to the table and carefully and accurately positioned by the feed screws. Sufficient power is available for almost any modelling work. The major drawback is that it takes much more time to set up than to do the cutting.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT COLUMN SAWING

A special arbor threads onto spindle screw. The bushing is trued on the machine while turning to size to fit the required blade mounting hole. The same mandrel is used on the C5 milling machine but with a shank for mounting in chuck.

Although some juggling of mandrels is required, very accurate straight line cuts can be made on the table or in mid-air at almost any angle. Great for kit bashing.

The original Unimat saw table has a rather crude 3 1/2" X 4" table with two blade slits and a bar stock fence that could be set to some small angles. It is nounted by vertical post in a hole in a bracket which is clamped on the carriage. By pivoting aroubd the post, blade to slot alignment can be set. While vertical post adjustment set the blade exposure aboe table. Final adjustnent of blade in slot us done by feed screws, Using the standard arbor, the blade cut line barely cleared the end of the motor. Blades were limited to about 2 1/2" to clear the ways. With the low speed attachment mounted the motor could not be dropped enough to clear wide sheets, unless the head stock raising block were used or the unit were mounted on sheet a 3/4" plywood to permit the pulley to drop below the bed base level. With a headstock raising block, a 3 1/2" blade could be used, In the end very precise cuts can be made, if the right blades were found. Standard blades have a 16 mm hole. Unfortunately the arbor screw is 12 mm preventing use with common 10 mm saws.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT DB200 TABLE SAW.

Later a new 6" X 8" table was developed for the Unimat SL, with a blade guard, a fully adjustable fence plus longitudinal and cross slots for an angle guide. With a new design of motor brush holders the head stock raising block was definitely required. The mount is very similar and the arbor remained the same.

Note: Adjust brightness and contrast for optimum viewing.

UNIMAT SL TABLE SAW

BACK TO METHODS

BACK TO DRILLING UNIMAT

BACK TO TOOLS INDEX